A kind of ultra-light ultra-wear-resistant rubber and preparation method thereof

A super wear-resistant and rubber technology, applied in the field of materials, can solve the problems of difficult to achieve various structures of rubber molds, multi-color production, difficult to control the size of finished products, unsatisfactory anti-slip effect, etc., to achieve the best tear resistance and anti-slip effect. good anti-slip effect and small specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

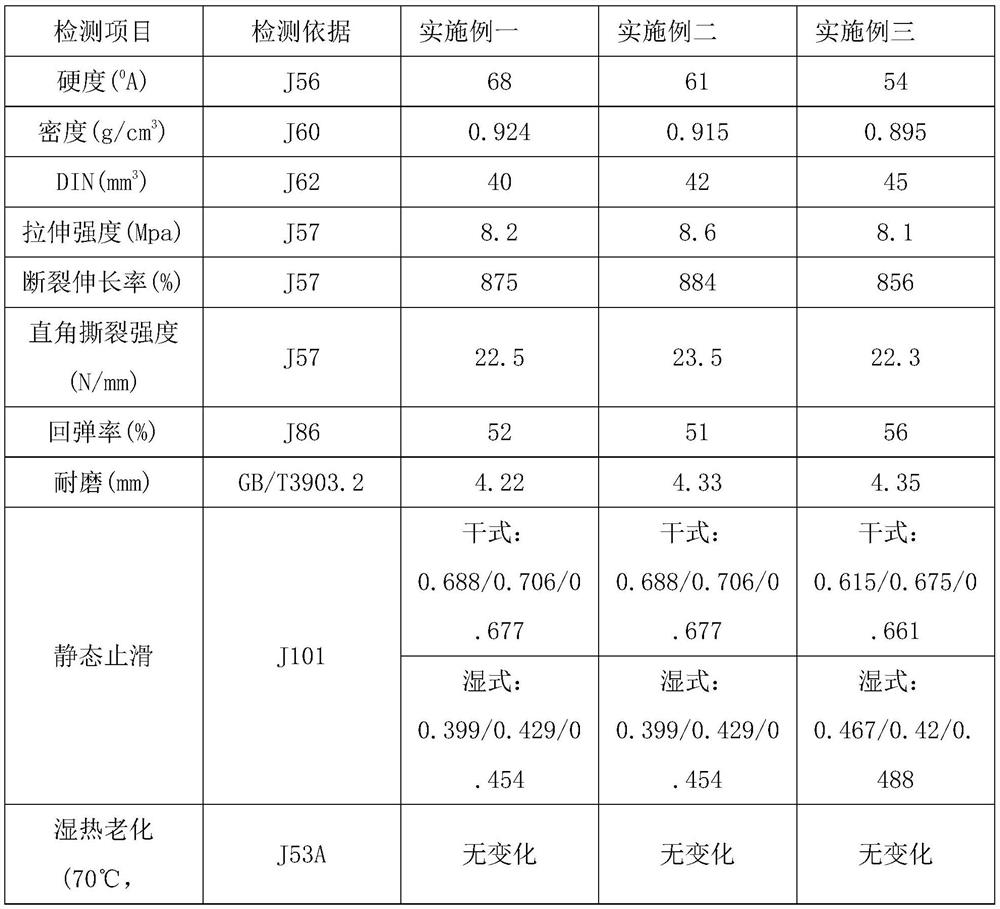

Embodiment 1

[0027] The invention provides an ultra-light and ultra-wear-resistant rubber, which comprises 45 parts of polyolefin elastomer, 20 parts of polybutadiene rubber, 20 parts of olefin block copolymer, 20 parts of polyisoprene rubber, 5 parts of filler, 1.5 parts of zinc oxide, 0.88 parts of stearic acid, 4.5 parts of anti-wear agent, 0.5 parts of crosslinking auxiliary agent, 1 part of crosslinking agent and 1 part of foaming agent.

[0028] Among them, the model of polyolefin elastomer is LC170; the model of polybutadiene rubber is VCR412; the model of olefin block copolymer is OBC9107; the model of polyisoprene rubber is SVR3L; It is greater than or equal to 95%, and the specific surface area of zinc oxide is greater than or equal to 45; the crosslinking agent is odorless DCP; the foaming agent model is F-105 in-mold foaming agent.

[0029] The present invention also provides a method for preparing ultra-light and ultra-wear-resistant rubber, comprising the following steps: ...

Embodiment 2

[0039] An ultra-light and ultra-wear-resistant rubber, in parts by mass, comprising 40 parts of polyolefin elastomer, 35 parts of polybutadiene rubber, 12 parts of olefin block copolymer, 10 parts of polyisoprene rubber, and 3 parts of filler 1 part, 2 parts of zinc oxide, 1 part of stearic acid, 7 parts of anti-wear agent, 0.5 part of crosslinking auxiliary agent, 0.3 part of crosslinking agent and 0.5 part of foaming agent.

[0040] Among them, the model of polyolefin elastomer is LC175; the model of polybutadiene rubber is VCR617; the model of olefin block copolymer is OBC9107; the model of polyisoprene rubber is SKI-3S; The zinc content is greater than or equal to 95%, and the specific surface area of zinc oxide is greater than or equal to 45; the crosslinking agent is odorless DCP; the foaming agent model is F-78K in-mold foaming agent.

[0041] The preparation method of the above-mentioned ultra-light and ultra-wear-resistant rubber is basically the same as that of Exa...

Embodiment 3

[0043] An ultra-light and ultra-wear-resistant rubber, in parts by mass, comprising 30 parts of polyolefin elastomer, 40 parts of polybutadiene rubber, 15 parts of olefin block copolymer, 15 parts of polyisoprene rubber, and 3 parts of filler 1 part, 2 parts of zinc oxide, 1 part of stearic acid, 7 parts of anti-wear agent, 0.5 part of crosslinking auxiliary agent, 0.3 part of crosslinking agent and 0.8 part of foaming agent.

[0044]Among them, the model of polyolefin elastomer is LC565; the model of polybutadiene rubber is VCR617; the model of olefin block copolymer is OBC9107; the model of polyisoprene rubber is IR-2200; The zinc content is greater than or equal to 95%, and the specific surface area of zinc oxide is greater than or equal to 45; the crosslinking agent is odorless DCP; the foaming agent model is F-48 in-mold foaming agent.

[0045] The preparation method of the above-mentioned ultra-light and ultra-wear-resistant rubber is basically the same as that of Exam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com