A preparation method of quasi-low-dimensional bismuth-based perovskite nanomaterials

A technology of perovskite materials and nanomaterials, which is applied in the field of preparation of quasi-low-dimensional bismuth-based perovskite nanomaterials, can solve the problems of complex synthesis methods, low yield, and low concentration of nanomaterial colloidal solutions, and overcome the problems of low concentration Effects of low and high fluorescence quantum yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

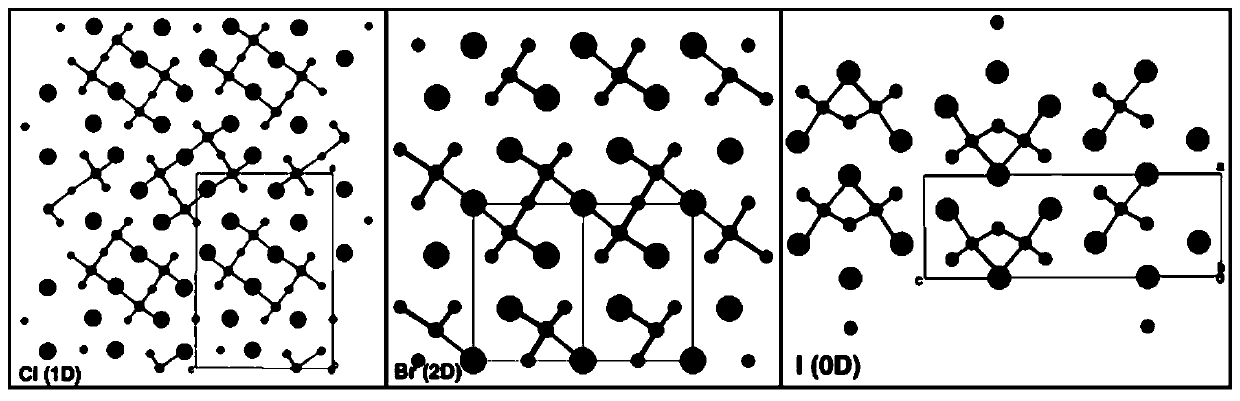

[0022] The preparation method of the quasi-low-dimensional bismuth-based perovskite nanomaterial in the present invention comprises the following steps: adopting the quasi-low-dimensional bismuth-based perovskite material MA 3 Bi 2 x 9 (X=Cl, Br, I) powder is used as raw material, amine is added as a stripping agent, and n-octane is used as a solvent (other solvents can also be used, as long as they can simultaneously meet: insoluble or slightly soluble perovskite material , needs to be able to dissolve the stripping agent; for example, n-hexane, toluene, methanol / n-octane mixed solvents, etc. can be used); the quasi-low-dimensional bismuth-based perovskite material is split by using the cell pulverizer to give strong energy and the stripping effect of the amine Open to realize the synthesis of new nanomaterials "from high to low, from existence to non-existence"; after centrifugation, take the supernatant to obtain the chemical formula MA 3 Bi 2 x 9 of nanomaterials.

[00...

Embodiment 1

[0028] In this embodiment, the quasi-low-dimensional bismuth-based perovskite nanomaterials, the specific preparation steps are as follows:

[0029] Step 1: Clean a glass bottle; for example, you can clean the white glass bottle with deionized water, acetone, isopropanol, and deionized water for ten minutes each, and then dry it with a nitrogen gun;

[0030] Step 2: Add 0.02mmol MA 3 Bi 2 Br 9 Put it into a glass bottle, add 5mL n-octane and 0.5mL oleic acid to the bottle as solvent and ligand respectively, and then add 100uL n-octylamine as stripping agent;

[0031] Among them, the raw material MA 3 Bi 2 Br 9 It is a quasi-2-dimensional bismuth-based perovskite powder;

[0032] Step 3: Put the glass bottle into the cell pulverizer and adjust the power to 45 (that is, the power is 300W) and start pulverizing for 30 minutes;

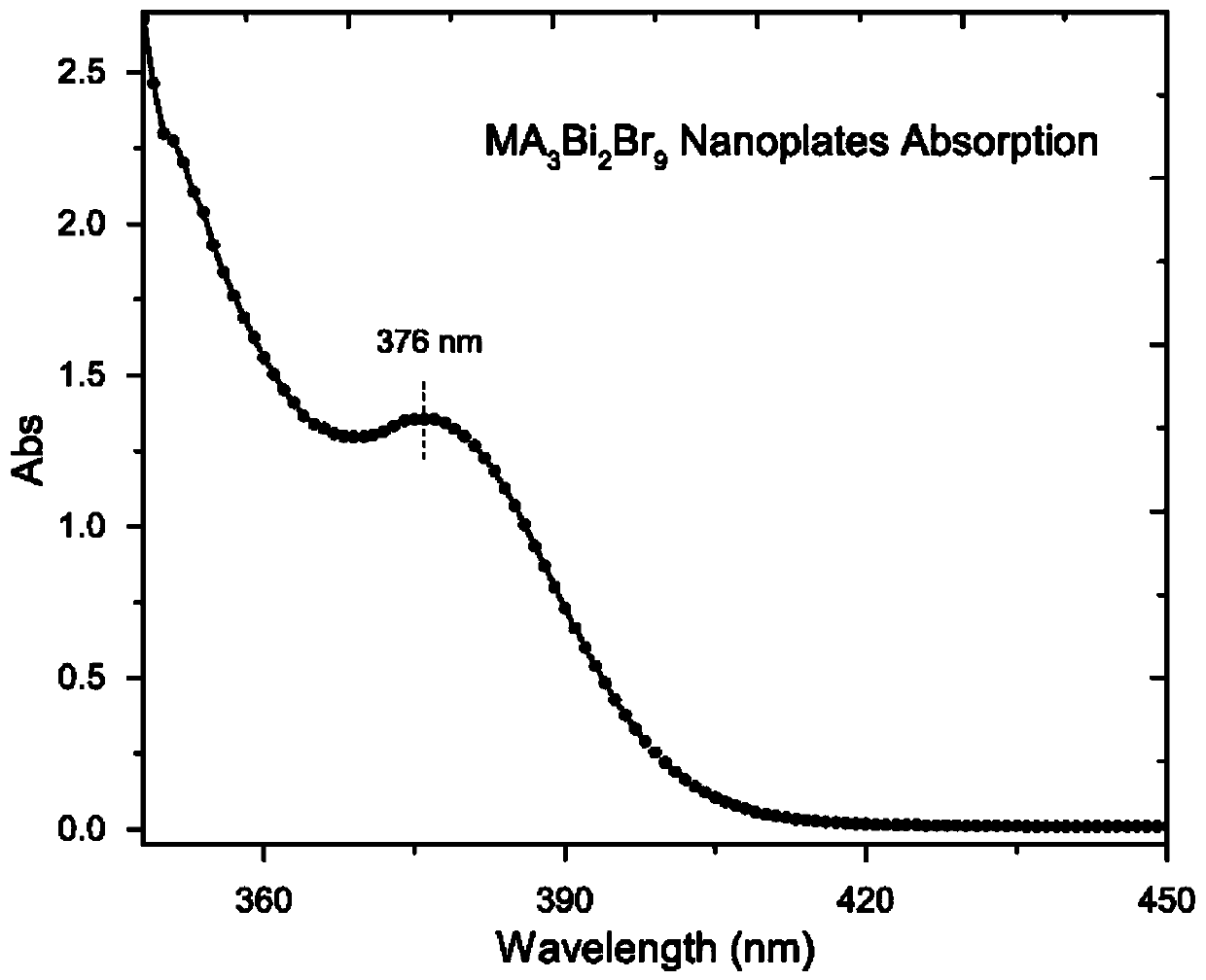

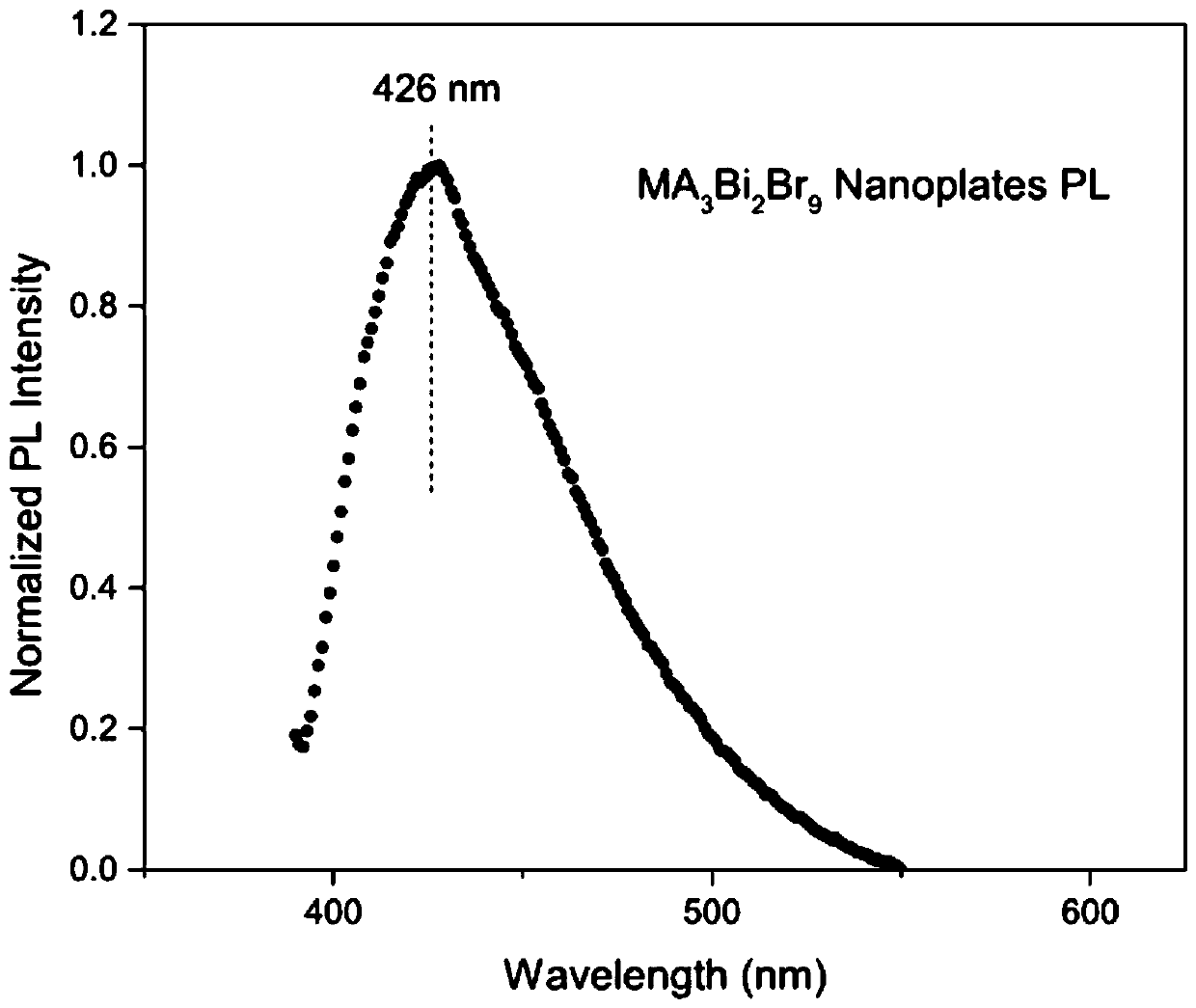

[0033] Step 4: Take out the suspension in the glass bottle, centrifuge it at 8000rpm and take the supernatant to obtain a pale yellow colloidal so...

Embodiment 2

[0035] In this embodiment, the quasi-low-dimensional bismuth-based perovskite nanomaterials, the specific preparation steps are as follows:

[0036] Step 1: Clean a glass bottle; wash the white glass bottle with deionized water, acetone, isopropanol, and deionized water for ten minutes each, and then dry it with a nitrogen gun;

[0037] Step 2: Add 0.02mmol MA 3 Bi 2 I 9 Put it into a glass bottle, add 5mL n-octane and 0.5mL oleic acid to the bottle as solvent and ligand respectively, and then add 200uL n-octylamine as stripping agent;

[0038] Among them, the raw material MA 3 Bi 2 I 9 It is a quasi-0-dimensional bismuth-based perovskite powder;

[0039] Step 3: Put the glass bottle into the cell pulverizer, adjust the power to 45 and start pulverizing for 30 minutes;

[0040] Step 4: Take out the suspension in the glass bottle, centrifuge it at 8000rpm and take the supernatant to obtain a light red Bi-based perovskite quantum dot colloidal solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com