Water permeable brick for sponge city and preparation method thereof

A technology of sponge city and permeable bricks, which is applied to paving with prefabricated blocks, climate change adaptation, pavement details, etc., can solve the problems of rainwater loss, aggravating the city, low production efficiency, etc., to increase strength and prevent impurities from clogging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

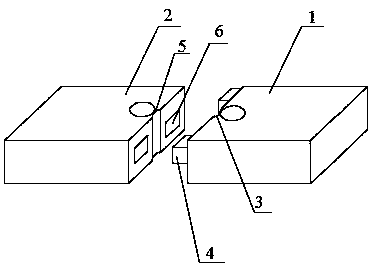

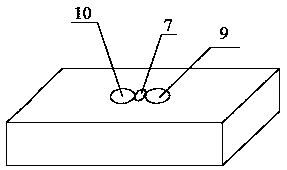

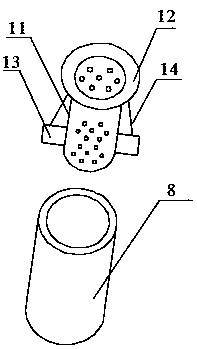

[0028] A permeable brick for sponge city, the permeable brick includes a main body of the permeable brick, the main body of the permeable brick includes an upper layer and a lower layer, the end surface of the upper layer is provided with several placement grooves, the placement grooves A luminous block is embedded, and the luminous block is a light storage type luminous material.

[0029] The upper layer includes the following raw materials in parts by weight: 35 parts of quartz sand, 10 parts of cement, and the lower layer includes the following parts by weight of raw materials: 45 parts of blast furnace heavy slag, 5 parts of silica fume, 10 parts of cement, 6 parts Crushed pebbles, 0.5 parts of water-based epoxy acrylic emulsion.

[0030] The thickness of the upper layer is 15 mm, and the thickness of the lower layer is 40 mm.

[0031] A preparation method for a permeable brick for a sponge city, comprising the steps of:

[0032] Step 1, preparation of the lower layer: h...

Embodiment 2

[0039] A permeable brick for sponge city, the permeable brick includes a main body of the permeable brick, the main body of the permeable brick includes an upper layer and a lower layer, the end surface of the upper layer is provided with several placement grooves, the placement grooves Embedded with luminous blocks, the luminous blocks are light-storing luminous materials, the upper layer includes the following raw materials in parts by weight: 38 parts of quartz sand, 11 parts of cement, and the lower layer includes the following raw materials in parts by weight: 48 parts Blast furnace heavy slag, 7 parts of silica fume, 11 parts of cement, 7 parts of crushed pebbles, 0.7 parts of water-based epoxy acrylic emulsion.

[0040] The thickness of the upper layer is 18 mm, and the thickness of the lower layer is 45 mm.

[0041] A preparation method for a permeable brick for a sponge city, comprising the steps of:

[0042] Step 1, preparation of the lower layer: heating the blast ...

Embodiment 3

[0048] A permeable brick for sponge city, the permeable brick includes a main body of the permeable brick, the main body of the permeable brick includes an upper layer and a lower layer, the end surface of the upper layer is provided with several placement grooves, the placement grooves A luminous block is embedded, and the luminous block is a light storage type luminous material.

[0049] The upper layer includes the following raw materials in parts by weight: 40 parts of quartz sand, 12 parts of cement, and the lower layer includes the following parts by weight of raw materials: 50 parts of blast furnace heavy slag, 9 parts of silica fume, 12 parts of cement, 8 parts crushed pebbles, 1 part water-based epoxy acrylic emulsion.

[0050] The thickness of the upper layer is 20 mm, and the thickness of the lower layer is 50 mm.

[0051] A preparation method for a permeable brick for a sponge city, comprising the steps of:

[0052] Step 1, preparation of the lower layer: heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com