Multidimensional composite tensile-bearing-type anti-seismic joint device

A composite and tensile technology, which can be applied in earthquake resistance, building type, protective buildings/shelter, etc., can solve the problems of poor anti-overturning ability and low energy consumption efficiency of anti-seismic joint devices, so as to improve the anti-seismic and shock absorption. Efficiency, preventing sudden collapse to both sides, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with examples, but the implementation of the present invention is not limited thereto.

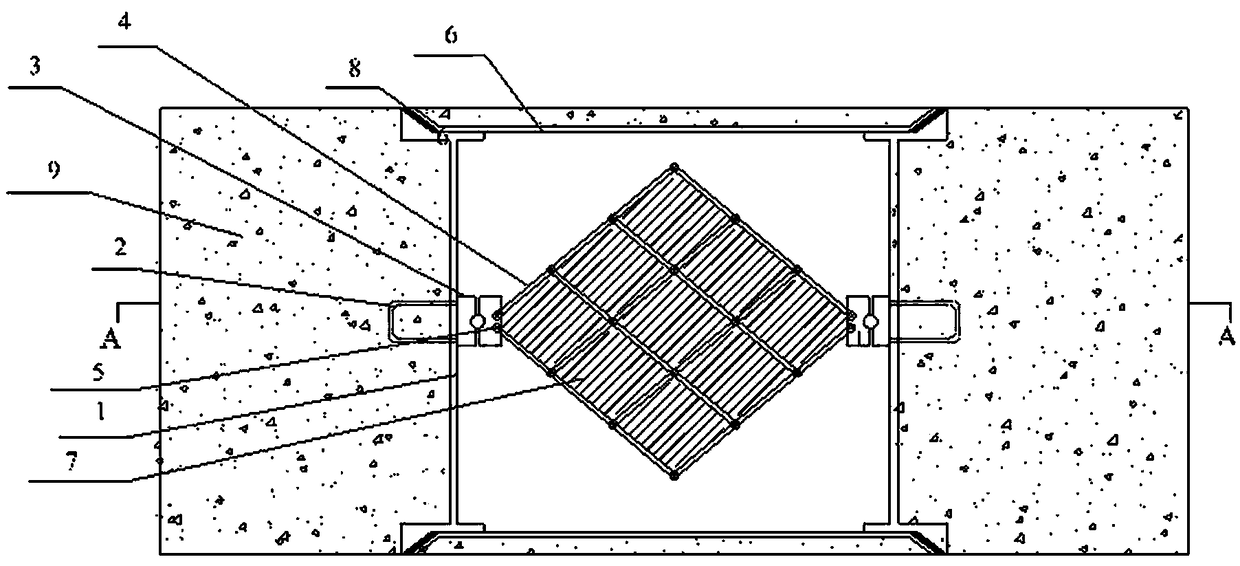

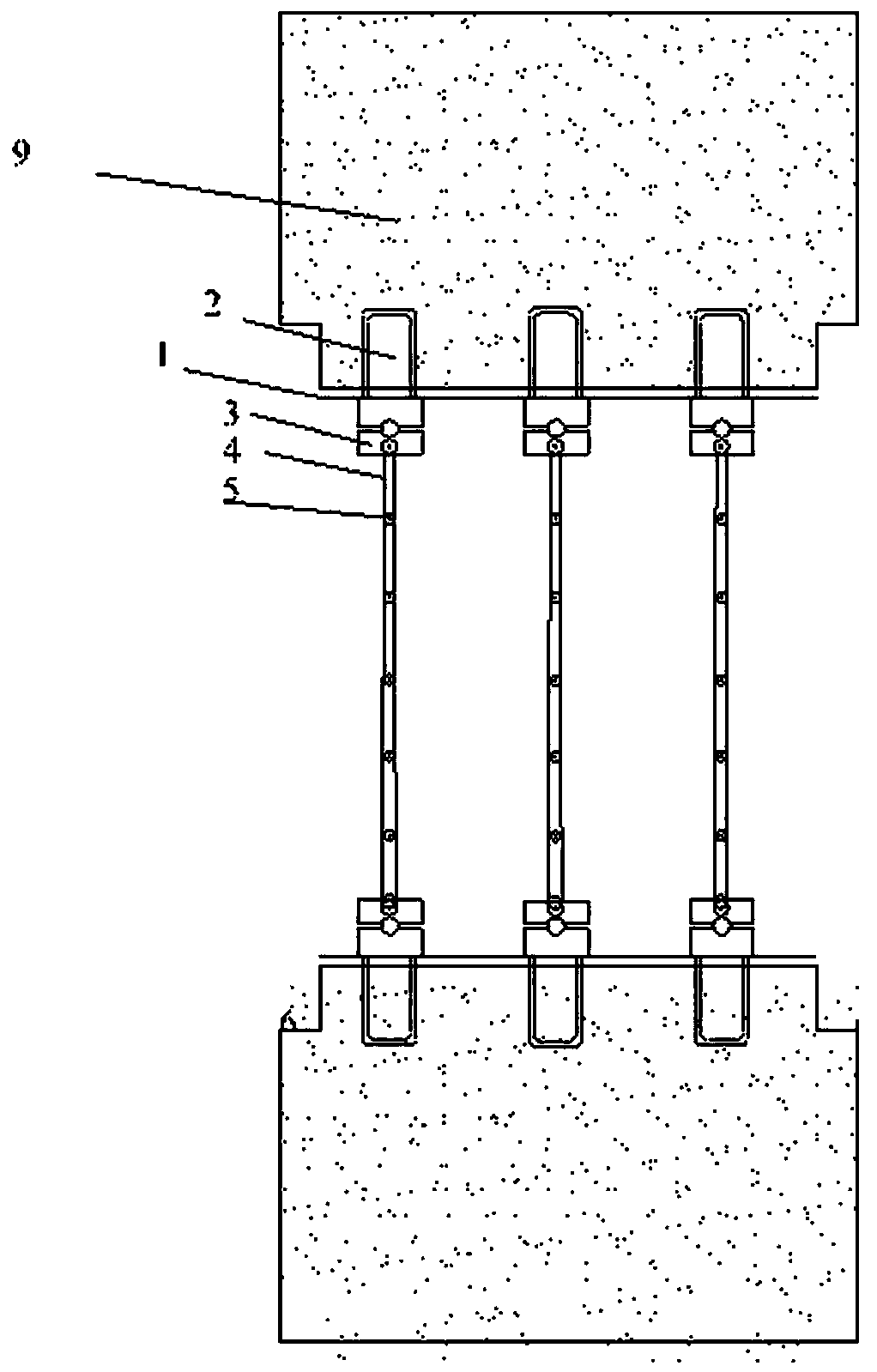

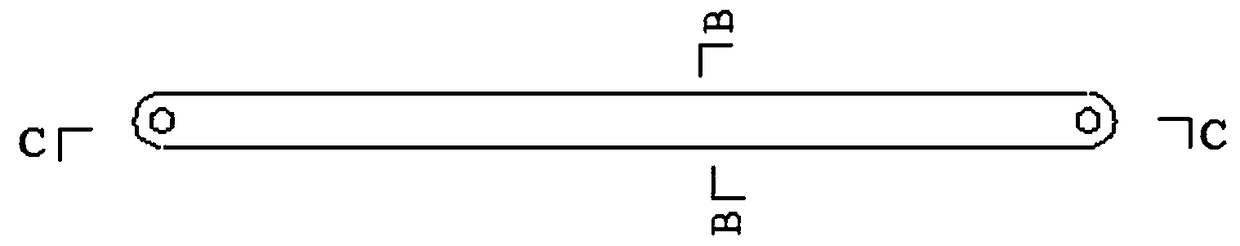

[0021] Such as figure 1 with figure 2 As shown, a multi-dimensional composite tension-type seismic joint device is composed of a special-shaped steel base 1, an anchoring member 2, a ball-cage universal coupling 3, a shock-absorbing energy-consuming tension rod 4, a bolt 5, and an aluminum alloy Cover plate 6, rubber cushion 7 and rubber strip 8; the special-shaped steel base 1 is made of 15CrMoR steel plate, which has good toughness, shape and weldability. The anchoring member 2 is an earring-type steel bar, welded to On the outer side of the special-shaped steel base 1, the anchoring member 2 and the concrete beam 9 are poured together, so that the special-shaped steel base 1 and the concrete beam 9 are connected into a whole through the anchoring member 2, which is The buildings on both sides of the seis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com