A method for detecting the failure of a rubber sealing ring

A rubber sealing ring and detection method technology, applied in the field of rubber sealing rings, can solve the problems of low operability, time-consuming, material and manpower, and high disassembly costs, and achieve simple operation process, high practical operability, and low detection cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for detecting the failure of a rubber sealing ring for long storage with bullets, which is carried out in sequence with the following steps:

[0031] Step 1: Select 6 new nitrile rubber seals (height 3mm) used on the ammunition packaging barrel, and use the same pressure direction and compression ratio as the storage process of the ammunition for stress loading. Specifically, non-standard clamps are used First carry out radial stress loading on each new rubber sealing ring, the compression ratio is 22.3%, the compression ratio calculation formula is P=(h 0 -h 1 ) / h 0 *100%, where h 0 Is the initial height of the rubber seal, h 1 It is the specified height reached by the rubber sealing ring after stress loading;

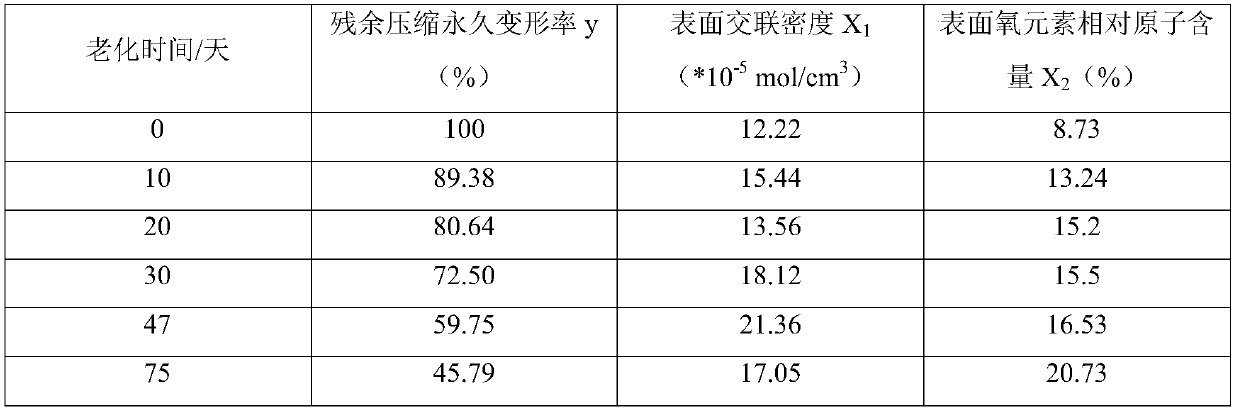

[0032] Step 2: Put the 6 nitrile rubber seals under load in step 1 into the damp heat test box, set the damp heat test conditions to 80℃, 90% RH, and carry out the damp heat aging test with different aging cycles; 6 nitrile rubber seals were aged 0, 10, 20,...

Embodiment 2

[0058] A method for detecting the failure of a rubber sealing ring for long storage with bullets, which is carried out in sequence with the following steps:

[0059] Step 1: Select 6 new nitrile rubber seals (height 2.5mm) used on the ammunition pilot, and use the same pressure direction and compression ratio as the storage process of the ammunition for stress loading. Specifically, non-standard The fixture first loads each new rubber sealing ring with radial stress, the compression ratio is 25%, and the compression ratio calculation formula is P=(h 0 -h 1 ) / h 0 *100%, where h 0 Is the initial height of the nitrile rubber seal ring, h 1 It is the specified height reached by the nitrile rubber seal ring after stress loading;

[0060] Step 2: Put the 6 nitrile rubber seals in the loaded state in step 1 into the high temperature aging test box, set the high temperature test condition to 80 ℃, and carry out the high temperature aging test with different aging cycles; Nitrile rubber sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com