Depth imaging super-resolution microscopic imaging system

A microscopic imaging and super-resolution technology, applied in microscopes, analytical materials, material excitation analysis, etc., to achieve the effects of low photobleaching and phototoxicity, high imaging quality, and correction of aberrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

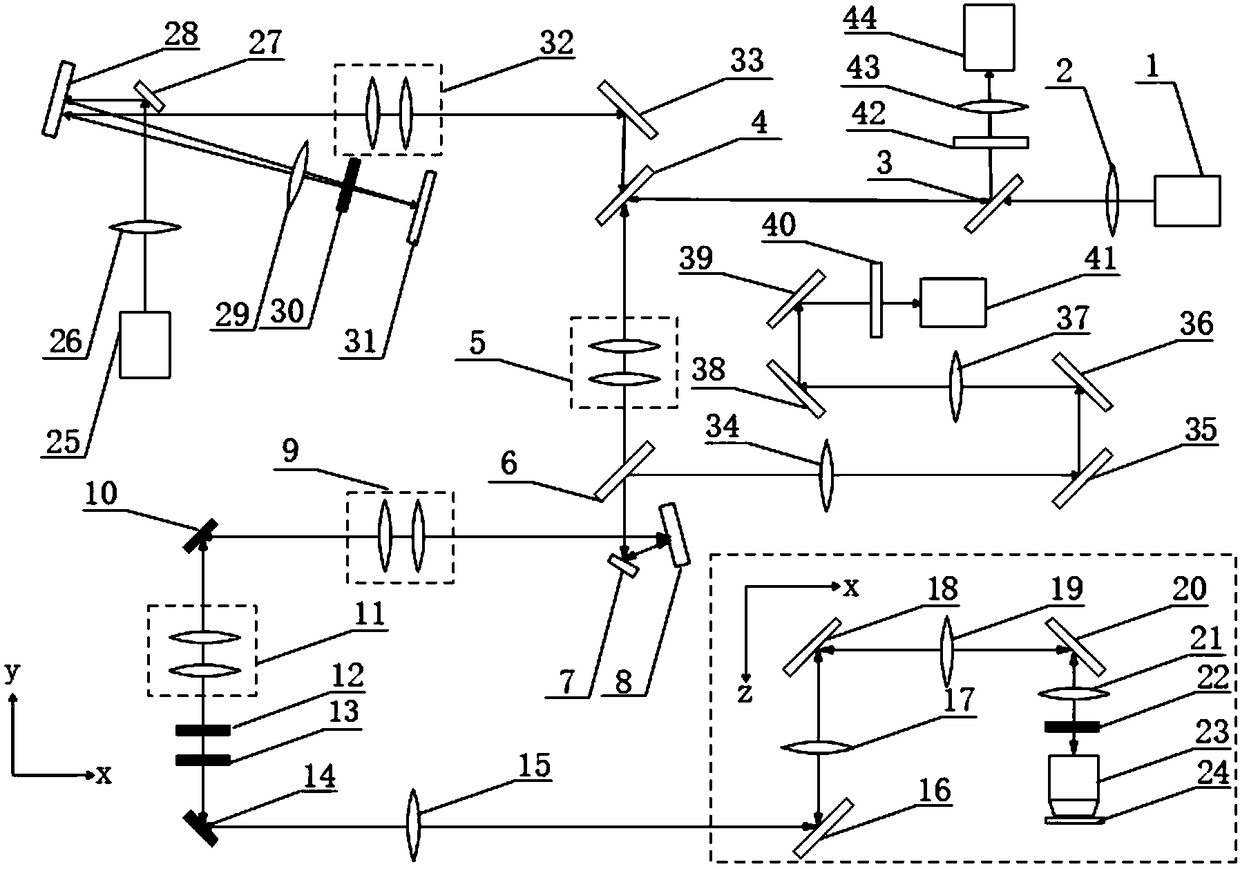

[0050] like figure 1 Shown is an optical path diagram of an embodiment of a depth imaging super-resolution microscope system structure of the present invention, the system of this embodiment includes:

[0051] The first laser 1, the first lens 2, the first dichroic mirror 3, the second dichroic mirror 4, the first telescopic system 5, the third dichroic mirror 6, the first mirror 7, the deformable mirror 8, the first mirror Two telescopic system 9, X-axis scanning galvanometer 10, third telescopic system 11, half-wave plate 12, first quarter-wave plate 13, Y-axis scanning galvanometer 14, second lens 15, second reflector Mirror 16, the third lens 17, the third reflection mirror 18, the fourth lens 19, the fourth reflection mirror 20, the fifth lens 21, the second quarter wave plate 22, the microscope objective lens 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com