Vertically-structured LED chip and manufacturing method thereof

An LED chip, vertical structure technology, applied in electrical components, nanotechnology, circuits, etc., can solve the problems of easy falling off of the Ag layer, chip leakage yield, and falling off of the Ag layer, so as to improve the light extraction efficiency, save costs, prevent shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 31

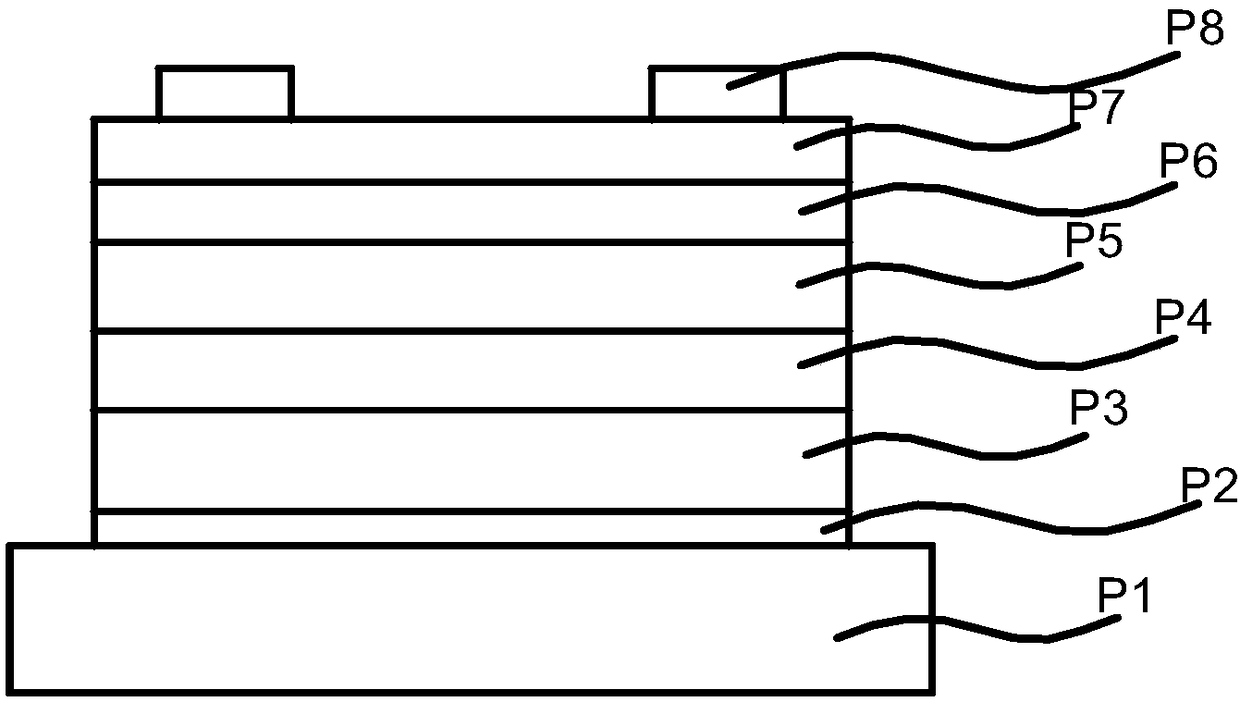

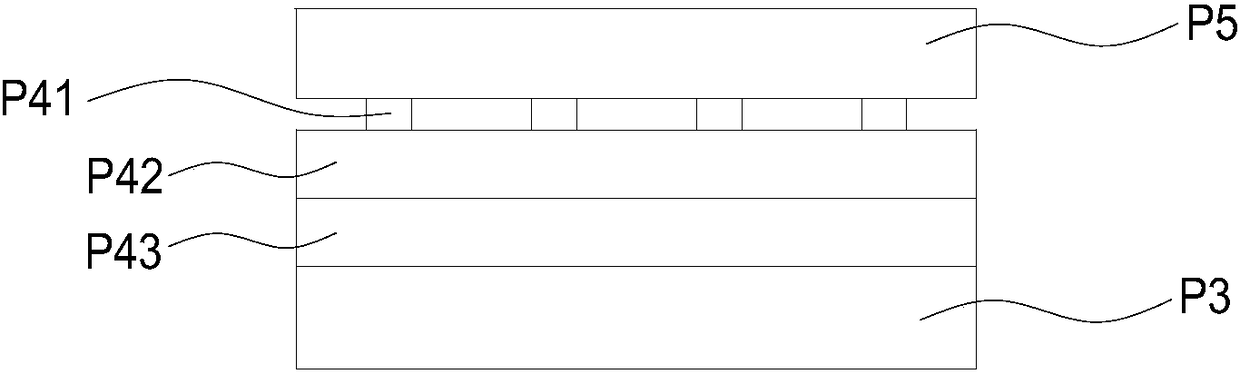

[0063] (1) Growth of LED epitaxial wafers: First, LED epitaxial wafers are epitaxially grown on Si substrates, including n-type doped GaN thin films grown on Si substrates (n-GaN layer P7), grown on n-type doped GaN thin films On the InGaN / GaN quantum well (that is, the InGaN / GaN quantum well layer P6), and the p-type doped GaN film (that is, the p-GaN layer P5) grown on the InGaN / GaN quantum well.

[0064] (2) The first step of growing the nano-point contact layer (metal layer growth): use electron beam evaporation equipment on the surface of the LED epitaxial wafer to evaporate the first contact layer metal Ni / Ag (that is, first evaporate a layer of Ni, and then evaporate Plating a layer of Ag), wherein the thickness of the Ni layer is 3nm; the thickness of the Ag layer is 100nm.

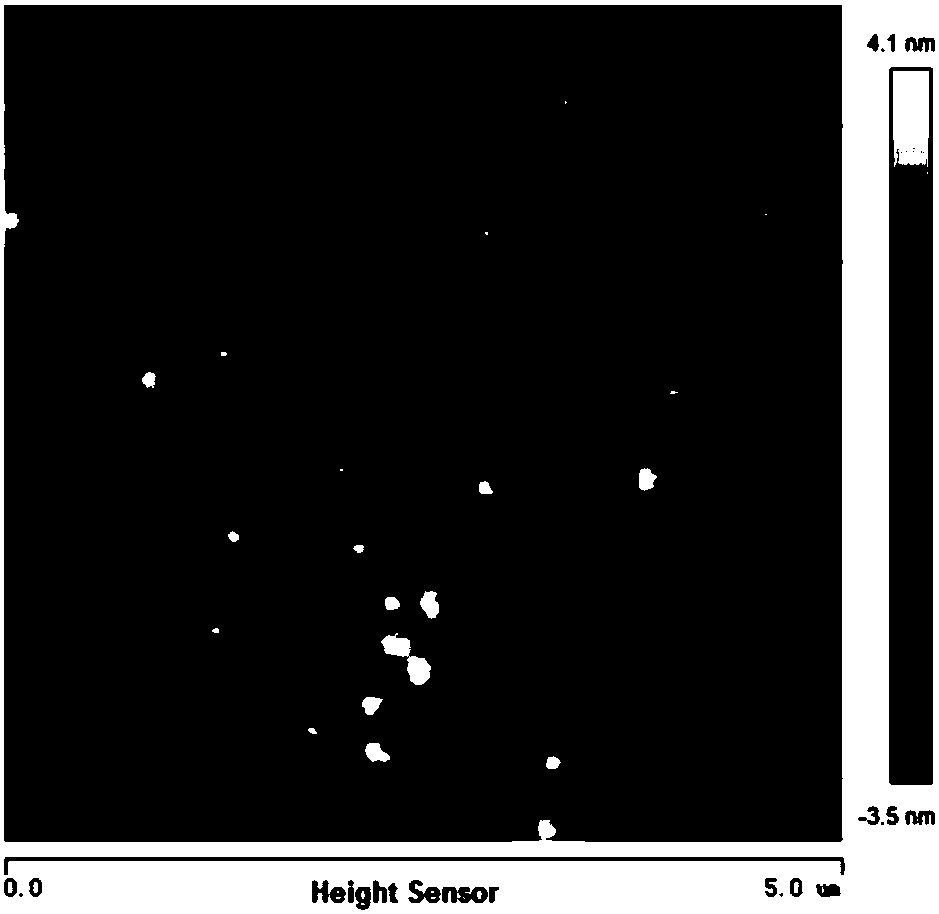

[0065] (3) The second step of growing the nano-point contact layer (metal layer annealing): performing high-temperature annealing on the first contact layer metal Ni / Ag in a rapid annealing furnac...

Embodiment 32

[0077] Example 32 The method for preparing a vertical structure LED chip is generally the same as that of Example 31, the difference lies in:

[0078] (3) The second step of growing nano-point contact layer (metal layer annealing): N 2 with O 2 The ratio of the amount of substances to N 2 :O 2 =20:1, the annealing temperature is 300°C, and the annealing time is 300s.

[0079] (4) The third step of growing nano-dot contact layer (wet etching to produce nano-dots): place the alloyed first contact layer prepared in (3) in the prepared acidic corrosion solution aqua regia, soak for 3s and take out .

[0080] (7) The second step of growing mirror layer (metal layer annealing): N 2 with O 2 The ratio of the amount of substances to N 2 :O 2 =1:20, the annealing temperature is 300°C, and the annealing time is 10s.

[0081] (10) Bonding and substrate transfer: the thickness of Sn is 3000nm, and the thickness of Au is 10nm. The LED epitaxial wafer is transferred to the conduct...

Embodiment 33

[0085] (1) Growth of LED epitaxial wafers: First, LED epitaxial wafers are epitaxially grown on Si substrates, including n-type doped GaN thin films grown on Si substrates (n-GaN layer P7), grown on n-type doped GaN thin films On the InGaN / GaN quantum well (that is, the InGaN / GaN quantum well layer P6), and the p-type doped GaN film (that is, the p-GaN layer P5) grown on the InGaN / GaN quantum well.

[0086] (2) The first step of growing the nano-point contact layer (metal layer growth): use thermal evaporation equipment on the surface of the LED epitaxial wafer to evaporate the first contact layer metal Pd / Ag (that is, first evaporate a layer of Pd, and then evaporate Plating a layer of Ag), wherein, the thickness of the Pd layer is 1.5nm; the thickness of the Ag layer is 150nm.

[0087] (3) The second step of growing the nano-point contact layer (metal layer annealing): performing high-temperature annealing on the first contact layer metal Pd / Ag in a rapid annealing furnace t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com