Lithium iron phosphate power battery with improved low temperature charge performance

A lithium iron phosphate, charging performance technology, applied in the field of lithium iron phosphate power batteries, can solve the problems of reducing the effective capacity of the negative electrode, reducing the degree of graphitization, etc., to reduce the negative electrode interface impedance, improve low-temperature performance, and have no negative impact on energy density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

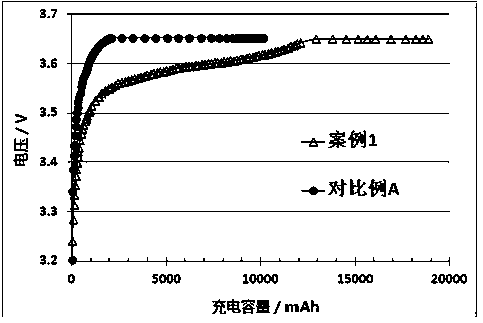

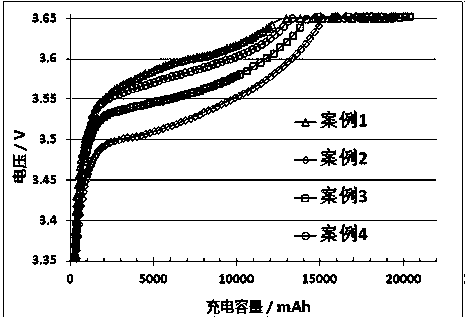

[0017] The invention discloses a lithium iron phosphate power battery with improved low-temperature charging performance, comprising a positive pole piece, a negative pole piece and an electrolyte.

[0018] The positive electrode sheet contains lithium iron phosphate, positive electrode composite conductive agent, positive electrode binder, and aluminum foil coated with conductive carbon on the surface. Lithium iron phosphate is prepared by using iron phosphate as the precursor, and its primary particle size is 100-300 nanometers; the positive electrode composite conductive agent contains conductive carbon black (SP), carbon nanotubes (CNTs), flake conductive graphite (KS- 6) Two or more components of vapor grown carbon fiber (VGCF), Ketjen black (ECP), and acetylene black (AB), the positive electrode binder is polyvinylidene fluoride (PVDF); the surface The aluminum foil coated with conductive carbon has a thickness of 15 microns as the base material of the aluminum foil, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com