Extraction method and applications of nymphaea tetragona essential oil

A technology of essential oil extraction and water lily, which is applied in the direction of essential oil/fragrance, fat production, etc., can solve the problems of easy decomposition of volatile oil, many impurities of essential oil, low yield of essential oil, etc., achieve high extraction efficiency, simple operation, and reduce experimental steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

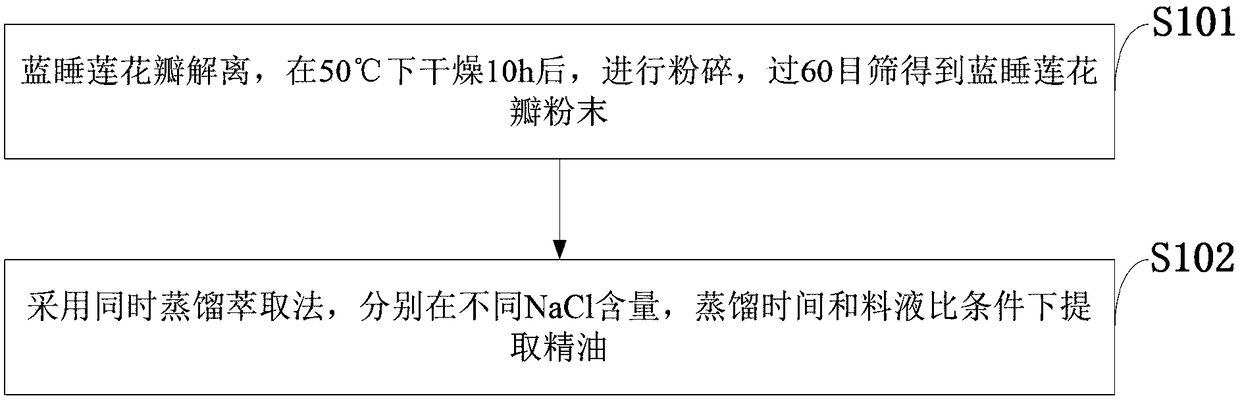

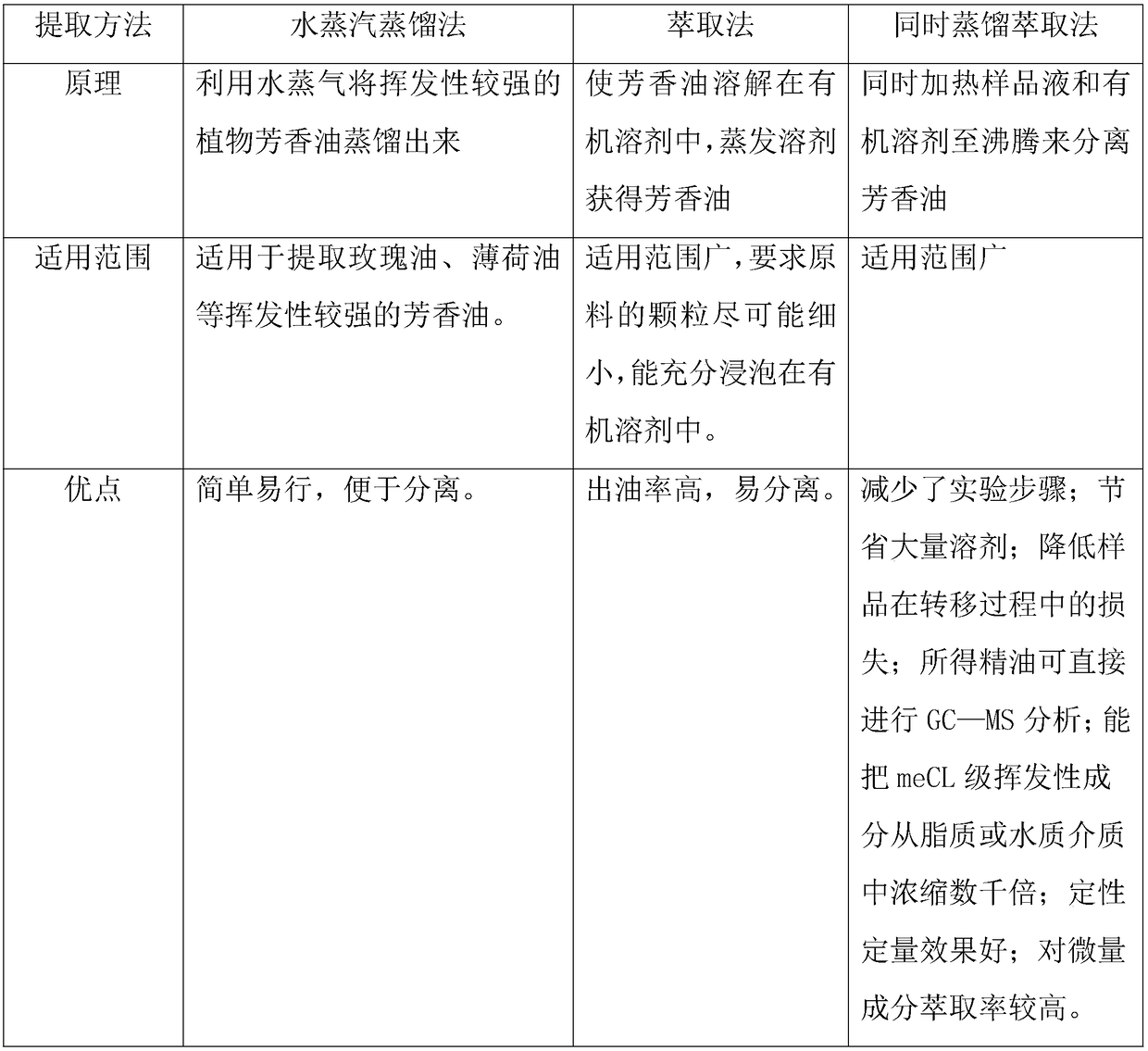

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: Accurately weigh 30g of blue water lily petal powder. Put it in a 1L flask, soak the petal powder with 600mL 5% NaCl solution, let it soak for 4 hours, install it on the left end of the simultaneous distillation extraction device, and heat it with an electric heating mantle until it boils; put 100mL of dichloromethane into a 500mL flask , connected to the right end of the simultaneous distillation and extraction device, and heated to 50°C with a constant temperature water bath to make it boil. After distilling and extracting for 2 hours at the same time, the flask with dichloromethane at the right end was removed, anhydrous sodium sulfate was added for drying, and the organic reagent was removed by rotary evaporation to obtain the essential oil product with a calculated yield of 0.10%.

Embodiment 2

[0031] Embodiment 2: Accurately weigh 30g of blue water lily petal powder. Put it in a 1L flask, soak the petal powder with 600mL10% NaCl solution, let it soak for 4 hours, install it on the left end of the simultaneous distillation extraction device, and heat it with an electric heating mantle until it boils; put 100mL of dichloromethane into a 500mL flask, Connect to the right end of the simultaneous distillation and extraction device, and heat it to 50°C with a constant temperature water bath to make it boil. At the same time, after distillation and extraction for 2 hours, the right end of the flask containing dichloromethane was removed, anhydrous sodium sulfate was added for drying, and the organic reagent was removed by rotary evaporation to obtain an essential oil product with a calculated yield of 0.14%.

Embodiment 3

[0032] Embodiment 3: Accurately weigh 30g of blue water lily petal powder, place it in a 1L flask, soak the petal powder with 600mL10% NaCl solution, let it soak for 4h, install it on the left end of the simultaneous distillation extraction device, and heat it to its peak with an electric heating mantle Boiling; put 100mL of dichloromethane into a 500mL flask, connect it to the right end of the simultaneous distillation and extraction device, and heat it to 50°C with a constant temperature water bath to make it boil. At the same time, after distillation and extraction for 4 hours, the right end of the flask containing dichloromethane was removed, anhydrous sodium sulfate was added for drying, and the organic reagent was removed by rotary evaporation to obtain an essential oil product with a calculated yield of 0.16%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com