Grain deep processing integrated production technology for producing distilled liquor, rice vinegar and feed

A distilled wine and deep processing technology, which is applied in the field of grain deep processing, can solve the problems of animal palatability and poor absorption, low nutrient content of feed, and poor taste of sparkling wine, etc., to achieve palatability and good absorption, rich nutrition and stable wine quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

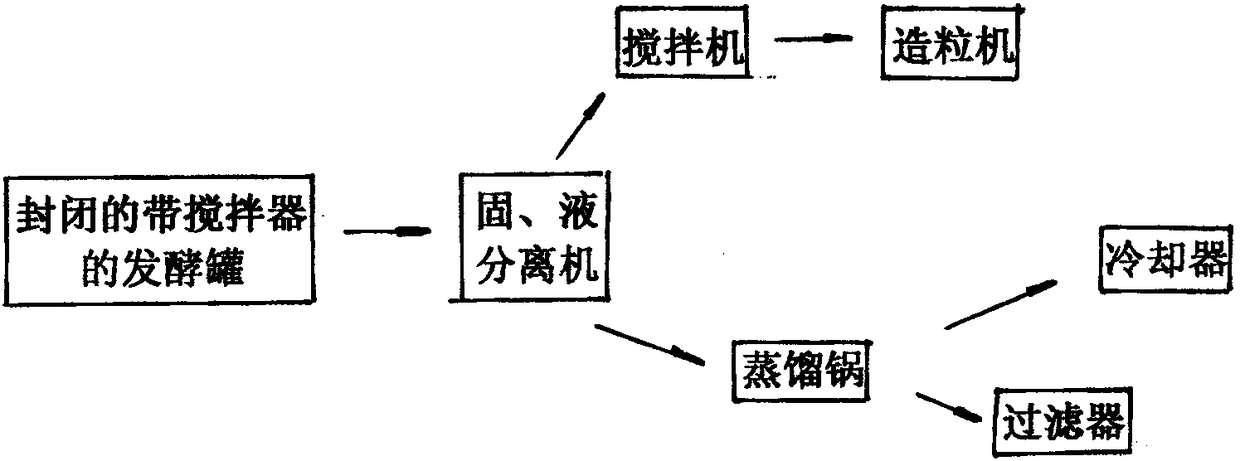

[0018] See figure 1 , the present invention integrates the production process of grain deep processing to prepare distilled wine, rice vinegar and feed. Taking corn, sorghum and rice as examples, the following steps are adopted:

[0019] 1. The raw materials for production are corn, sorghum and rice, and the distiller's koji is from Zhengzhongchun distiller's koji;

[0020] According to the ratio of grain: water: distiller's yeast = 100kg: 220~250kg: 0.6kg, the production raw materials are taken;

[0021] After crushing the grain, put it into water at a temperature of 25°C, add Zhengzhongchun wine koji and put it in a closed fermenter with agitator for fermentation. Fermentation temperature: the temperature outside the container is 30°C; time: 8-15 days to ferment and mature;

[0022] 2. The above-mentioned fermented and mature raw materials are pumped to the solid-liquid separator through pipelines and slag slurry for solid-liquid separation. The dry residue of grain solids ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com