Tunnel structure suitable for strong-expanding potential fault crushed zone

A tunnel structure and fracture zone technology, applied in tunnels, tunnel linings, shaft linings, etc., can solve problems such as slow release of expansion stress, impact on expressway safety, poor crack resistance, etc., to reduce surrounding rock pressure and ensure safety The effect of operation and good anti-crack performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

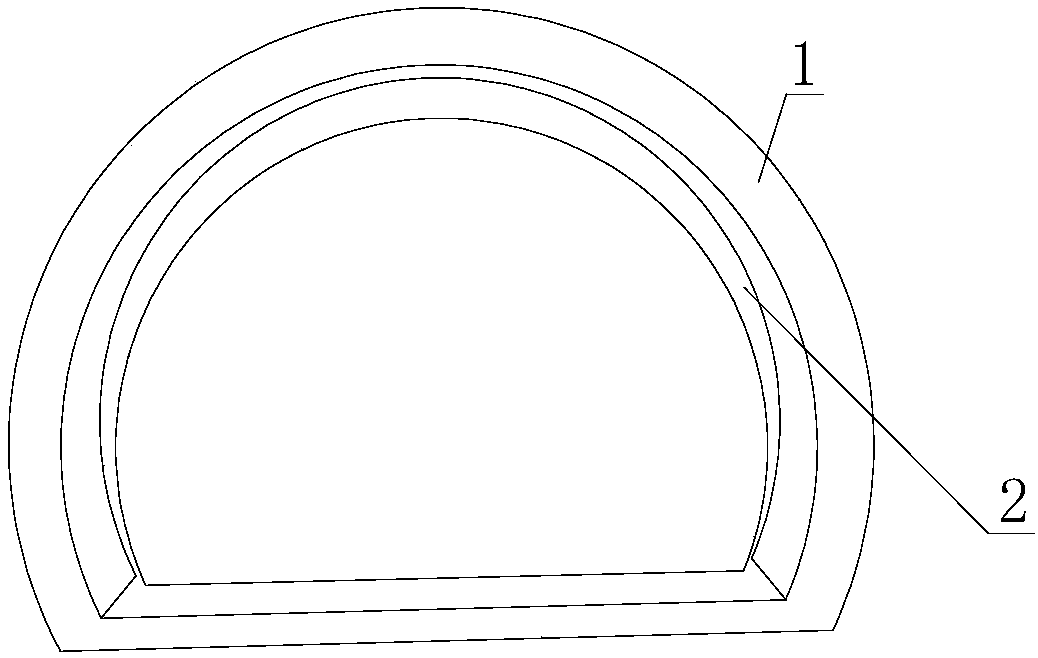

[0027] Example: such as figure 1 As shown, a tunnel structure suitable for the strong expansion potential fault fracture zone includes a tunnel outer arch ring 1 and a tunnel inner arch ring 2, and the tunnel outer arch ring 1 is made of rubber concrete.

[0028] The tunnel outer arch ring 1 made of rubber concrete has the following advantages: 1) The tunnel outer arch ring 1 is made of rubber concrete material, which has good impact resistance and deformation resistance, and can reduce the damage caused by the increase in the volume of expansive soil. Increased expansion pressure to avoid damage or reduce damage to the tunnel structure; 2) The outer arch ring 1 of the tunnel is made of rubber concrete material, which has good anti-crack performance and avoids water seepage and leakage to ensure the safety of the expressway Operation; 3) The outer arch ring 1 of the tunnel is made of rubber concrete material, which has a relatively dense structure and a certain expansion rate,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com