Integrated powder mixing vacuum drying device and powder mixing drying system

A vacuum drying device and an integrated technology, applied in the direction of solid-solid mixing, mixer, mixing method, etc., can solve the problems of low mixing efficiency, potential safety hazards, uneven mixing, etc., to ensure uniformity and facilitate scientific research work , better applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

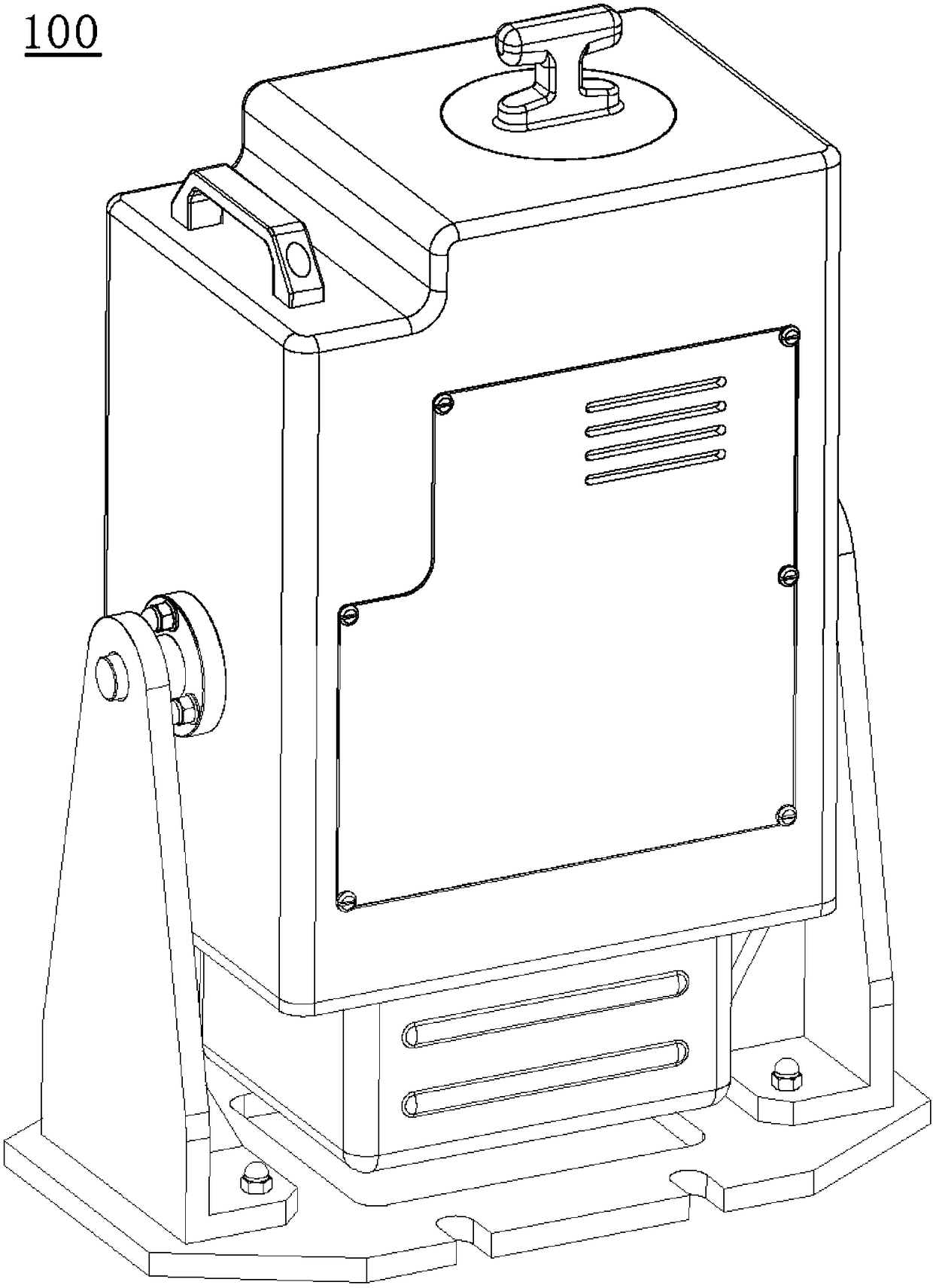

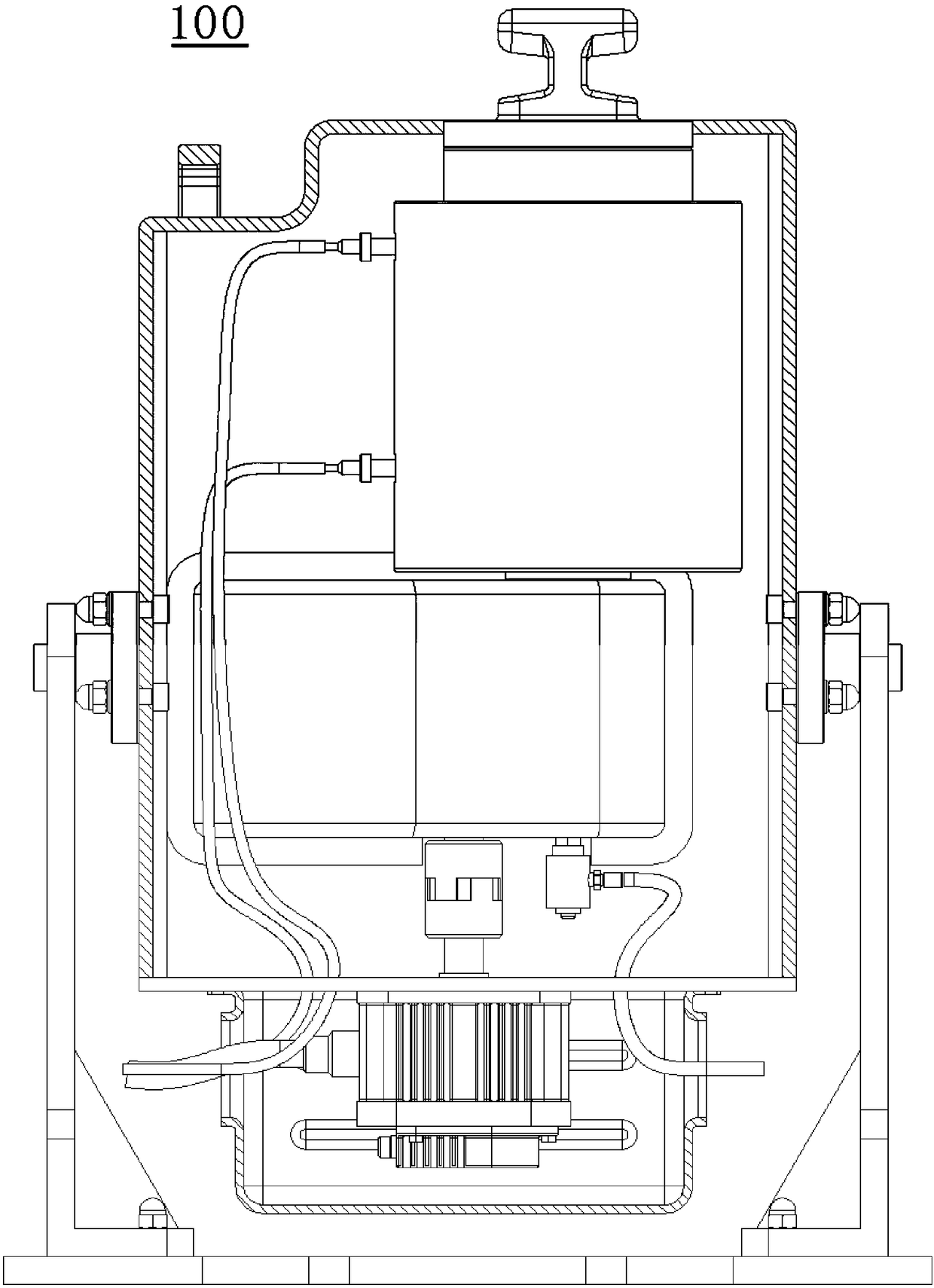

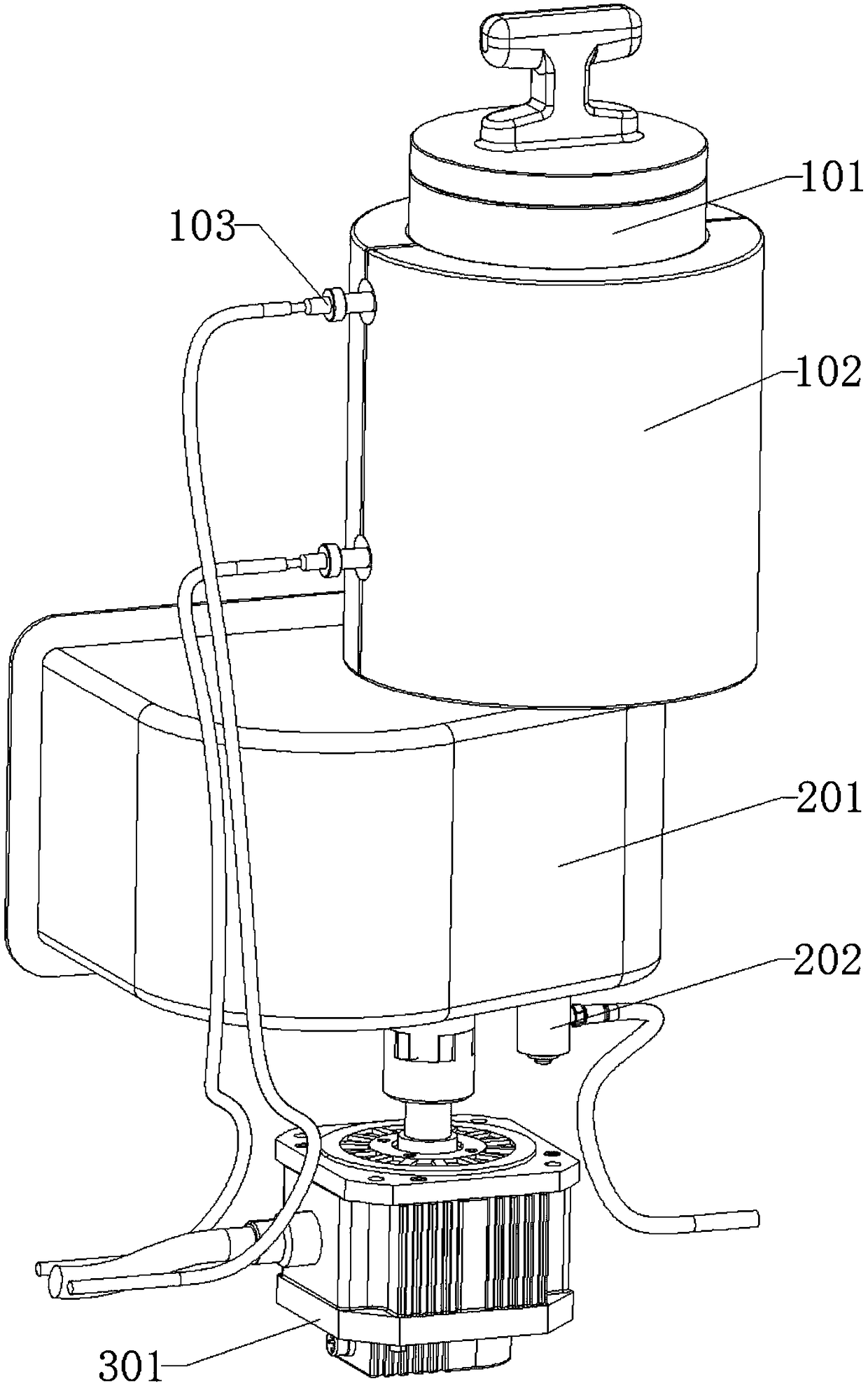

[0049] Please refer to Figure 1 to Figure 14 , this embodiment provides an integrated powder mixing vacuum drying device 100, including:

[0050] device base;

[0051] The main body of the device, the main body of the device is rotatably arranged on the base of the device, the main body of the device includes a housing, a powder mixing cylinder 101, a fixed-axis gear train 201, a driving motor 301 and an airtight joint for connecting with a vacuum pump;

[0052] The inside of the housing has an accommodating cavity, and the end of the housing away from the drive motor 301 has an opening, the drive motor 301 and the fixed-axis wheel train 201 are fixed in the housing, the cylinder head of the powder mixing cylinder 101 is located at the opening, and the output of the drive motor 301 The shaft is connected to the powder mixing cylinder 101 through a fixed shaft gear train 201;

[0053] The powder mixing cylinder 101 includes a central powder mixing roller 106, the fixed shaft...

Embodiment 2

[0073] This embodiment provides a powder mixing and drying system, including a vacuum pump and the integrated powder mixing vacuum drying device 100 in Embodiment 1, and the vacuum pump is connected to the airtight joint of the integrated powder mixing vacuum drying device 100 .

[0074] By using the integrated powder mixing vacuum drying device 100 in Example 1, the powder mixing and drying system can produce composite powder well, so that various powders can be mixed evenly, and are not easy to be wet and oxidized, and the production efficiency of composite powder can be improved.

[0075] To sum up, the integrated powder mixing vacuum drying device 100 of the present invention can realize uniform mixing and synchronous drying of metal powder and ceramic powder or powders of different alloy systems at the same time.

[0076]The innovative design of the internal structure of the device can fully ensure the uniformity of small batches of various types of powder mixing, and on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com