Super-gravity field high-frequency high-thrust single-degree-of-freedom horizontal vibrating table

A super-gravity field and high-thrust technology is applied in vibration testing, measuring devices, and testing of machine/structural components. It can solve the problems of piston rod movement hysteresis, limited load quality, and stagnation, and achieve reduced friction. Realize the effect of high frequency excitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

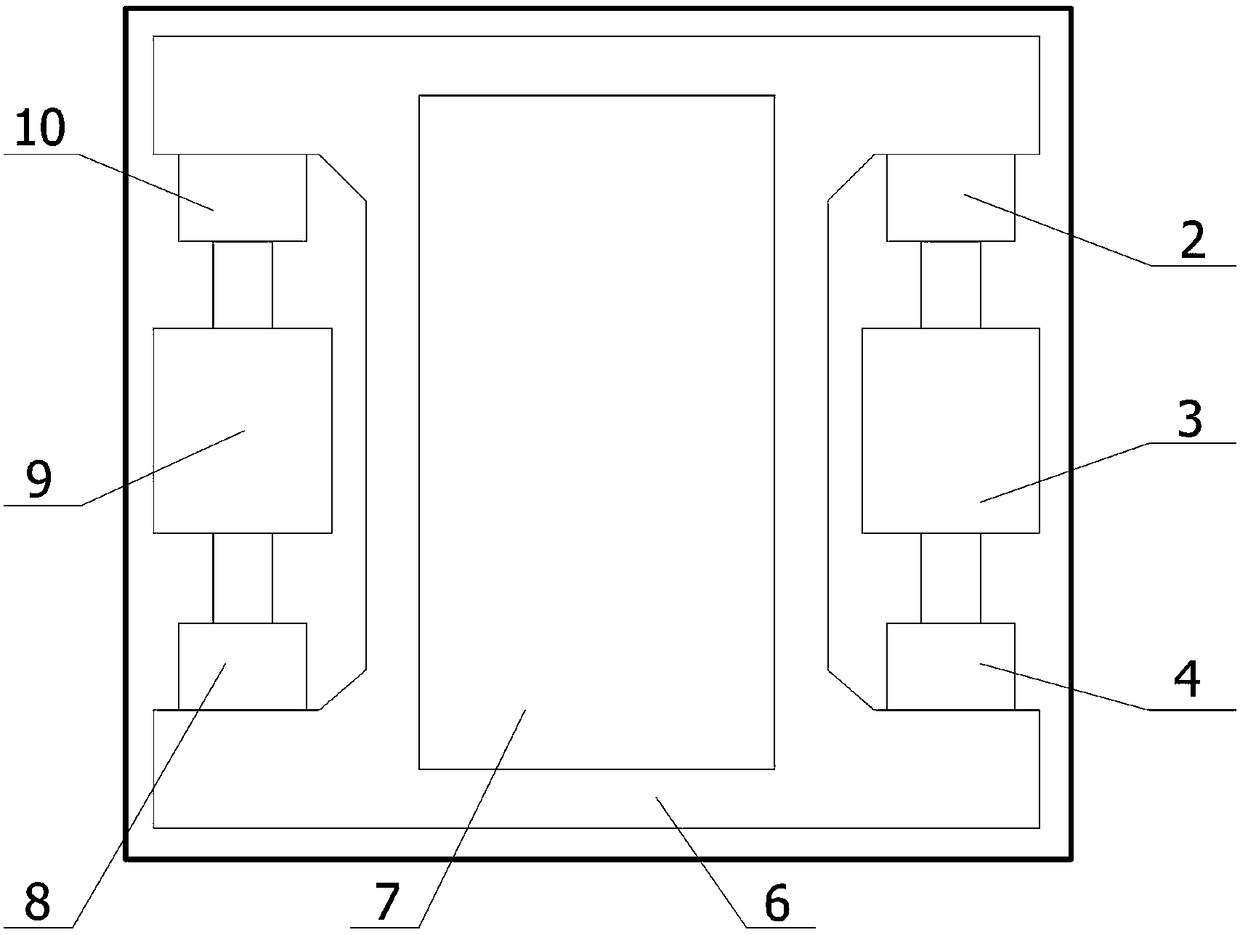

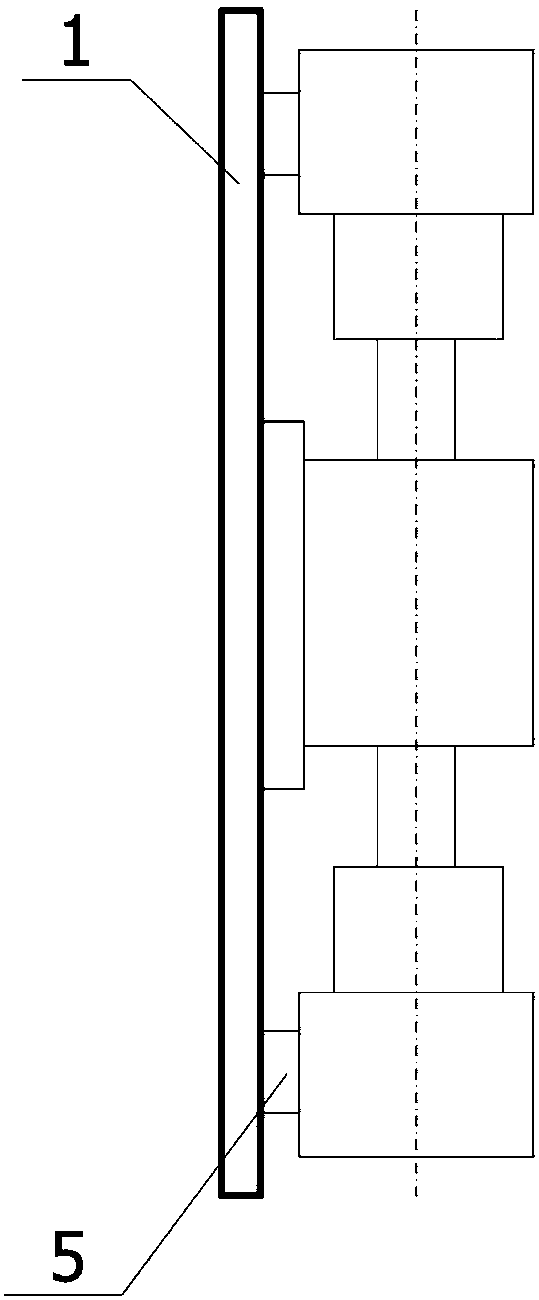

[0028] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, the present invention includes a foundation base plate 1, a vibrating table top 6 and a model box 7 for placing loads. The base base plate 1 is provided with a guide rail, and a slide block 5 is arranged in the guide rail. The block 5 is fixedly connected, and the guide rail is used as the motion support of the vibrating table 6, and is installed on the foundation base plate 1 according to the distribution of the load-bearing condition, and the hydraulic cylinder is fixed on the base base plate 1;

[0029] The vibration table 6 is an I-shaped structure, and the depressions on the left and right sides of the vibration table 6 are symmetrically installed with two hydraulic push mechanisms;

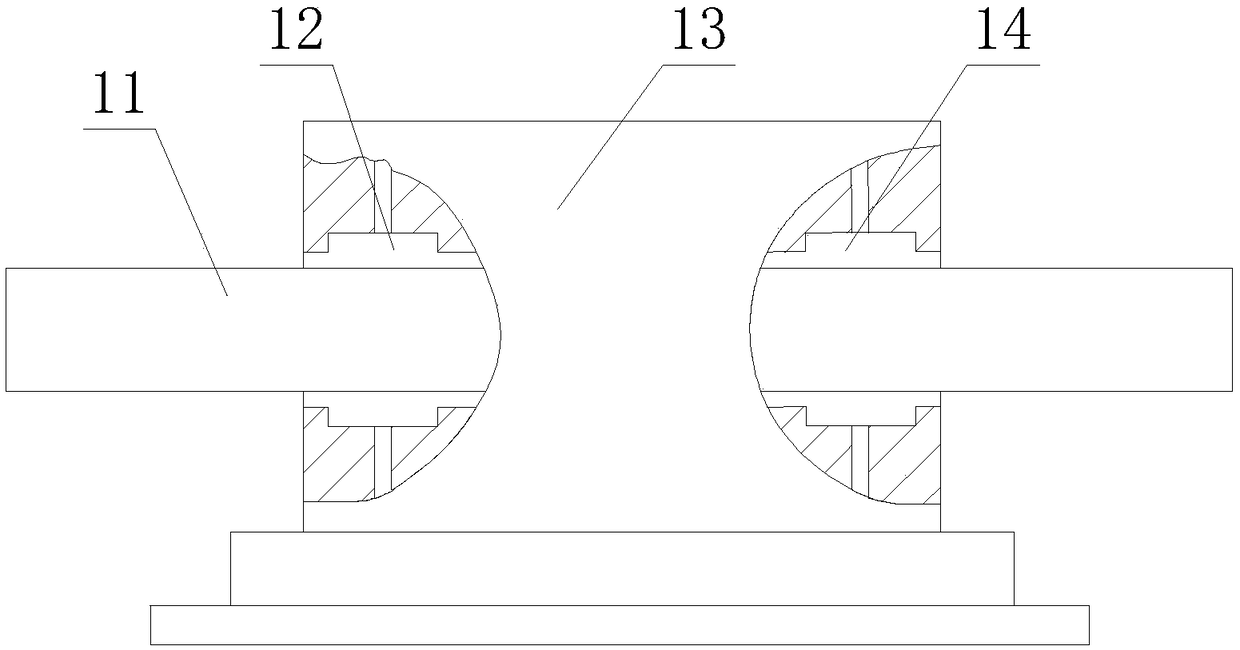

[0030] The hydraulic pushing mechanism includes a hydraulic cylinder and two connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com