Contact fatigue risk assessment method for carburized hardened gears considering residual stress

A residual stress, carburizing and hardening technology, applied in the testing of mechanical components, testing of machine/structural components, instruments, etc., can solve problems such as difficulty in evaluating gear contact fatigue failure, affecting equipment reliability, gear contact fatigue failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] like Image 6 Shown is the megawatt-class wind turbine gearbox that this gear sample serves. In practical engineering applications, the probability of failure of this sample gear is significantly higher than that of other gears.

[0053] The main parameters of the gear pair are as follows:

[0054]

[0055] Step 1. According to the formulas (1)~(2), by r 1 =684mm, r 2 = 136mm Calculate the comprehensive radius of curvature in the two-dimensional contact model as r = 41.76mm, from E 1,2 =2.10×10 11 Pa can obtain the equivalent elastic modulus as E=1.15×10 11 Pa. According to the above parameters, a two-dimensional contact model is established, and the established model is as follows: Figure 5 shown.

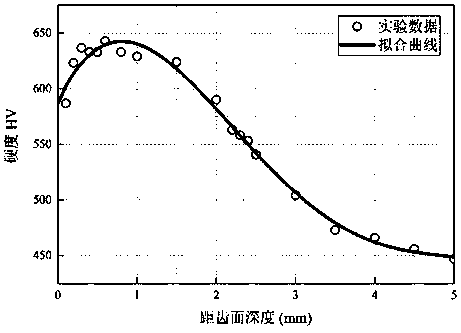

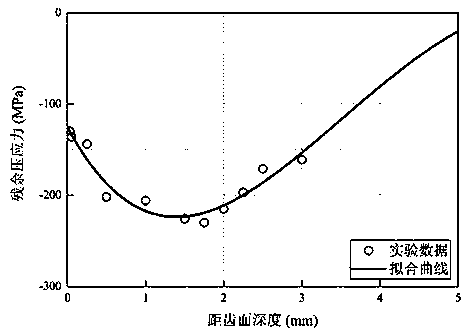

[0056] Step 2. The hardness and residual stress of the gear are tested respectively by Vickers hardness test method and X-ray diffraction method, and the obtained hardness distribution is as follows: figure 1 As shown, the residual stress distribution is as fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com