Pre-treatment system of infrared oil analyzer

A pretreatment and oil measurement technology, applied in the field of oil measurement instrument, can solve the problems of complicated device structure, large amount of extraction agent, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

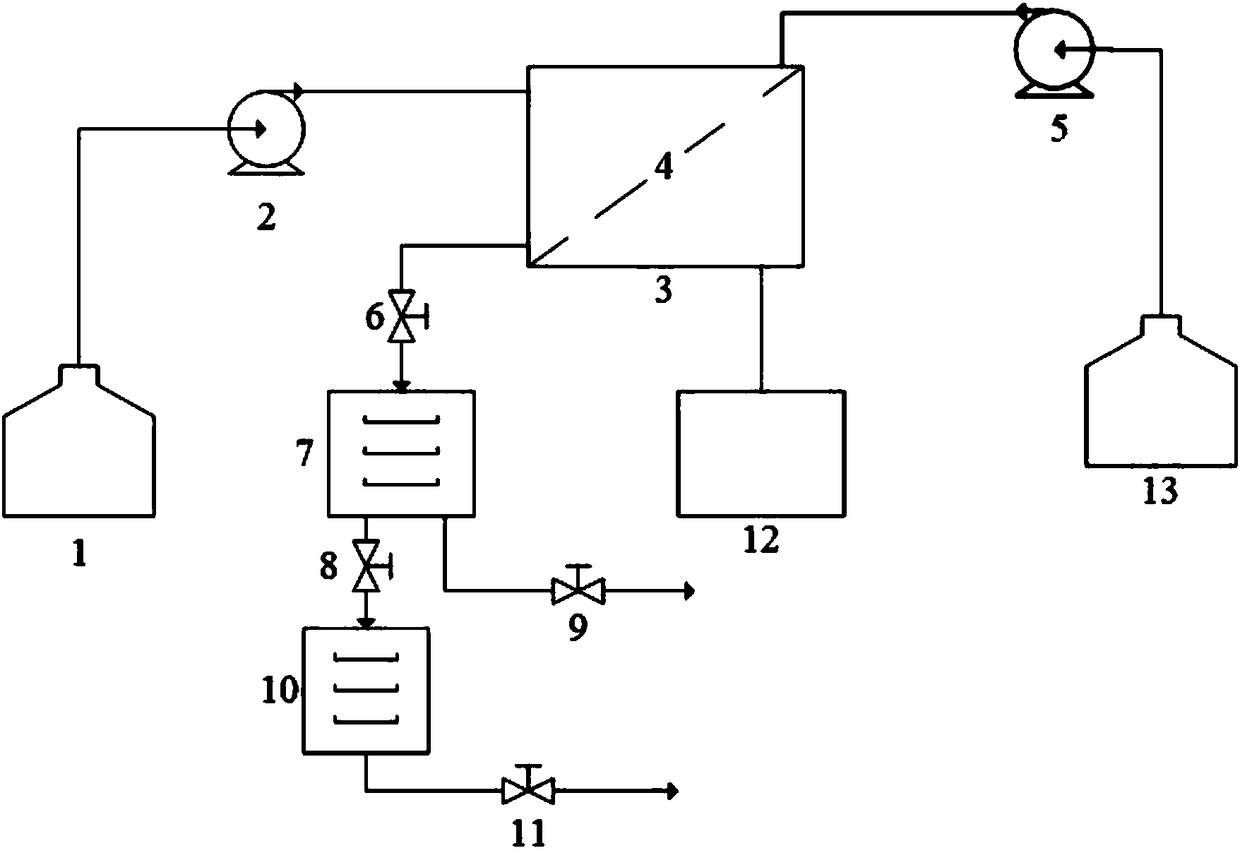

[0011] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0012] Such as figure 1 As shown, a pretreatment system of an infrared oil measuring instrument includes a sampling part, an oil-water film separation collection part and an adsorption separation part; the sampling part includes a sample bottle (1) and a sample pump (2); the oil-water film separation collection part Part comprises oil-water membrane separator (3), solvent pump (5), solvent bottle (13), waste water bottle (12) and regulating valve (6); Described adsorption separation part comprises Na 2 SO 4 Adsorption dehydration tank (7), MgSiO 3 Adsorption and deanimation vegetable oil tank (10) and regulating valves (8), (9) and (11); wherein said oil-water membrane separator (3) has an oblique oil-water separation membrane (4) inside, and the oil-water separation membrane (4) The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com