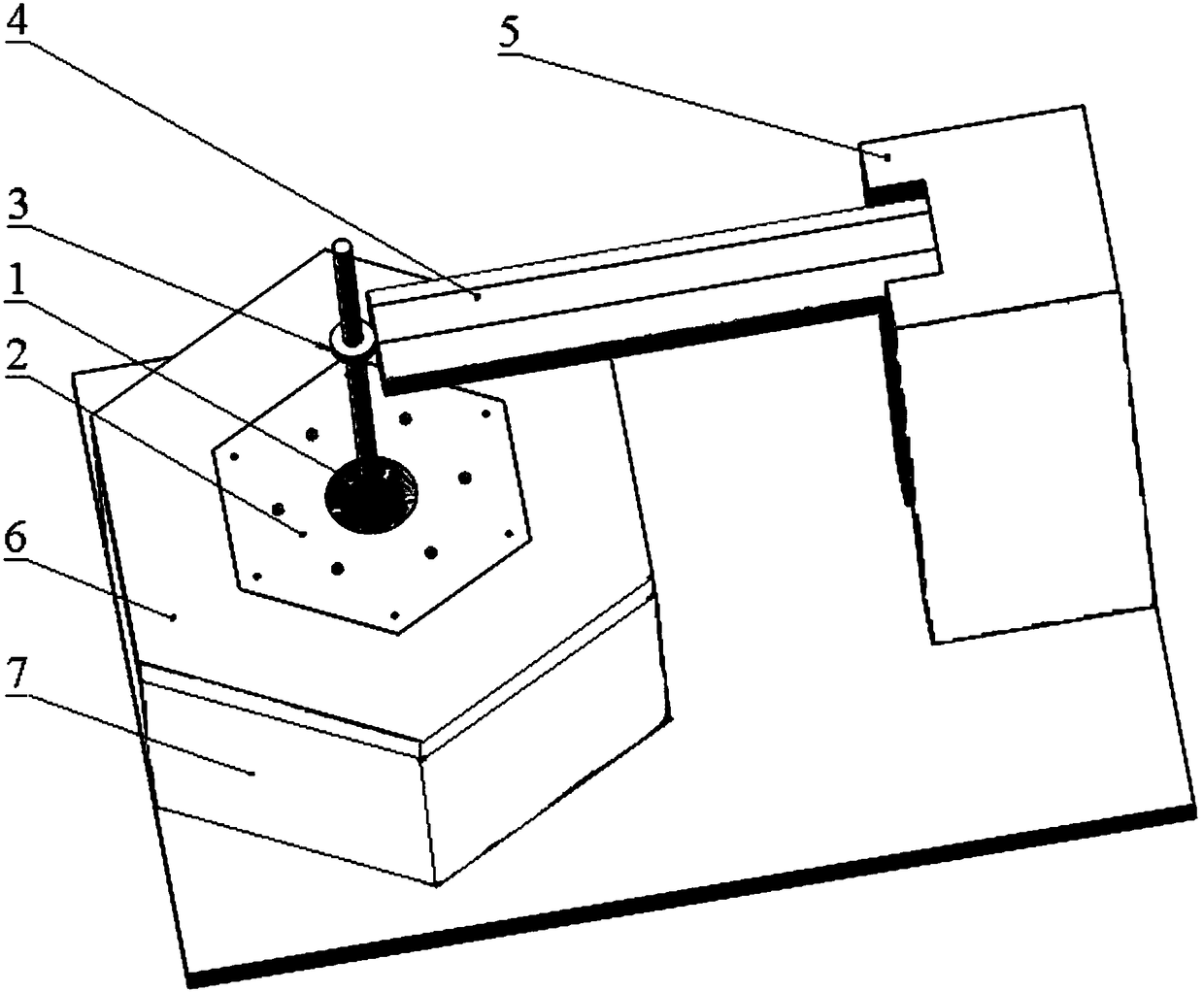

Device and method for focusing cold plasma to process 3D object

A cold plasma, 3D technology, applied in the direction of plasma, electrical components, etc., can solve the problems of small processing range, limited planar material processing, low processing efficiency, etc., and achieve industrial transformation, easy operation, and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

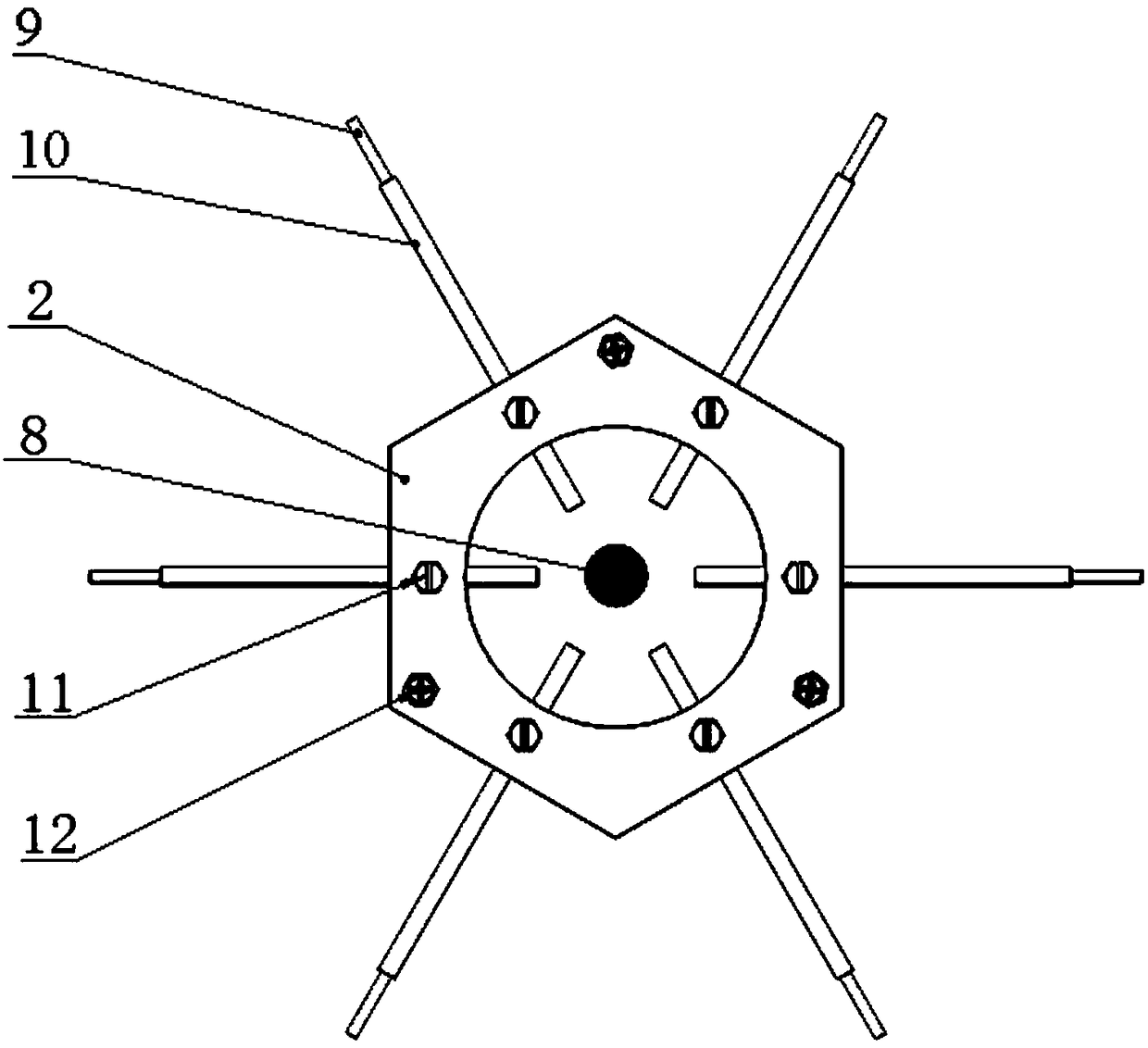

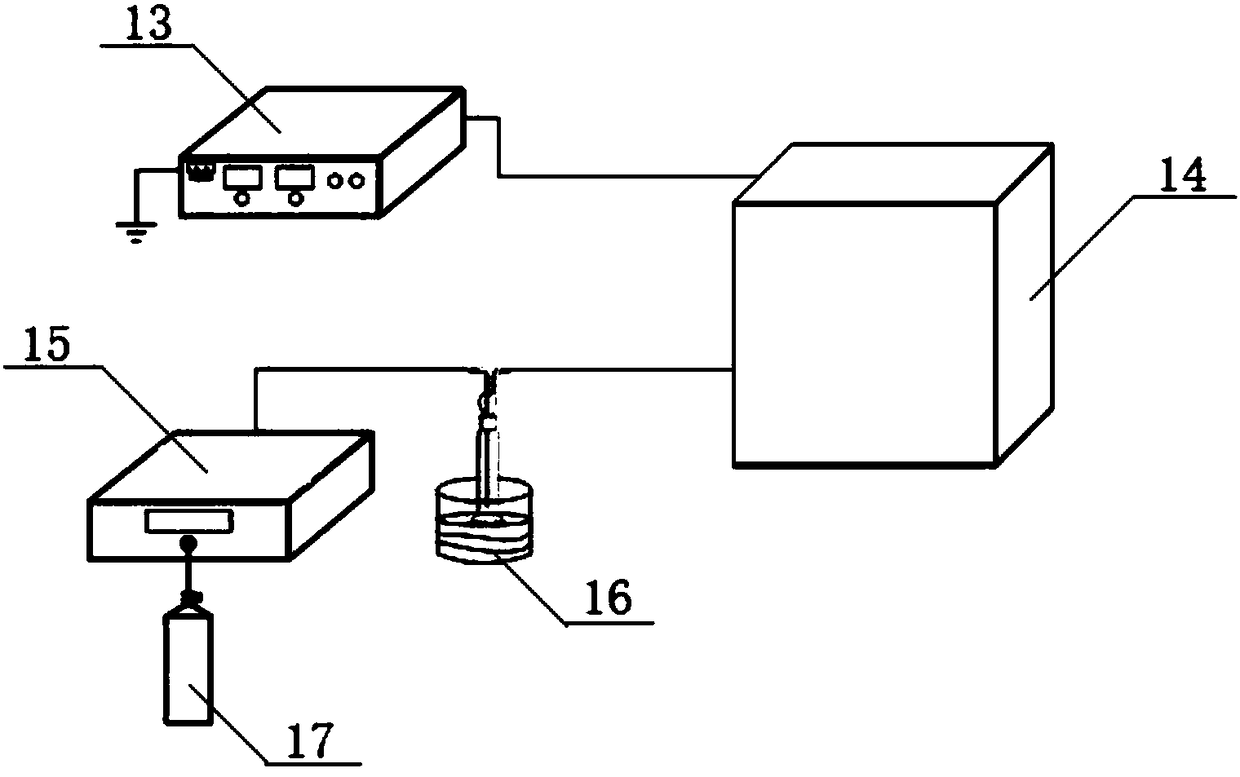

Embodiment 1

[0053] Direct modification of the surface of the cylindrical copper electrode: use six dielectric barrier tubes 10 to simultaneously excite the plasma to directly treat the surface of the copper electrode, set the total flow rate of the discharge excitation gas argon to 4slm, select the nanosecond pulse excitation power supply for the power supply 13, and apply a voltage of 12.3kV, frequency 1400Hz voltage, discharge under atmospheric pressure to generate low temperature plasma.

Embodiment 2

[0055] Deposition of TiO on the Surface of Cylindrical Copper Electrode 2 Thin film: use six dielectric barrier tubes 10 to simultaneously stimulate plasma to deposit TiO on the surface of copper electrodes 2 thin film, using TiCl 4 As a precursor, heat the scrubber bottle containing the precursor to 70°C in an oil bath, set the flow rate of the discharge excitation gas argon to 4slm, the flow rate of the carrier gas to 40sccm, and the flow rate of air to 40sccm, and heat the copper electrode to 100°C; The nanosecond pulse power supply is used as the excitation source, the discharge voltage is 13kV, the frequency is 13kHz, and the deposition process is 3min. After treatment, AFM (atomic force microscope) was used to observe and analyze the electrode surface. The test results show that the surface of the electrode is relatively rough before treatment, and there are a large number of pointed protrusions on the surface. At the same time, the surface of the electrode is randomly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com