Plasma generation module and air cleaner

An air purification device and plasma technology, applied in plasma, electrical components, deodorization, etc., can solve problems such as difficult to achieve surface glow plasma generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

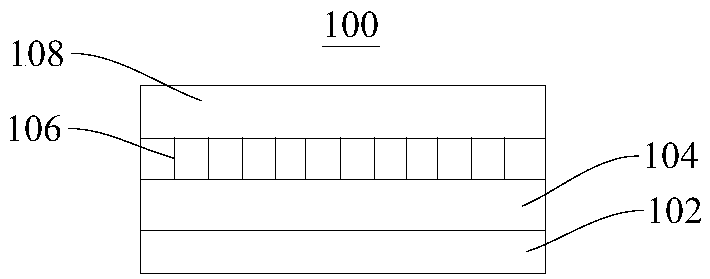

[0033] Please refer to figure 1 , figure 1 Shown is a schematic structural diagram of the plasma generating assembly 100 . The present embodiment provides a plasma generating assembly 100, which is mainly used for generating surface glow plasma.

[0034] In this embodiment, the plasma generating assembly 100 includes a power source (not shown in the figure), and a first electrode 102 , an insulating medium 104 , a second electrode 106 , and an insulating layer 108 connected in sequence. The first electrode 102 and the second electrode 106 are respectively connected to the positive pole and the negative pole of the power supply, that is, the first electrode 102 is used as a high voltage electrode, and the second electrode 106 is used as a ground electrode. The first electrode 102 , the insulating medium 104 , the second electrode 106 , and the insulating layer 108 are tightly bonded in sequence.

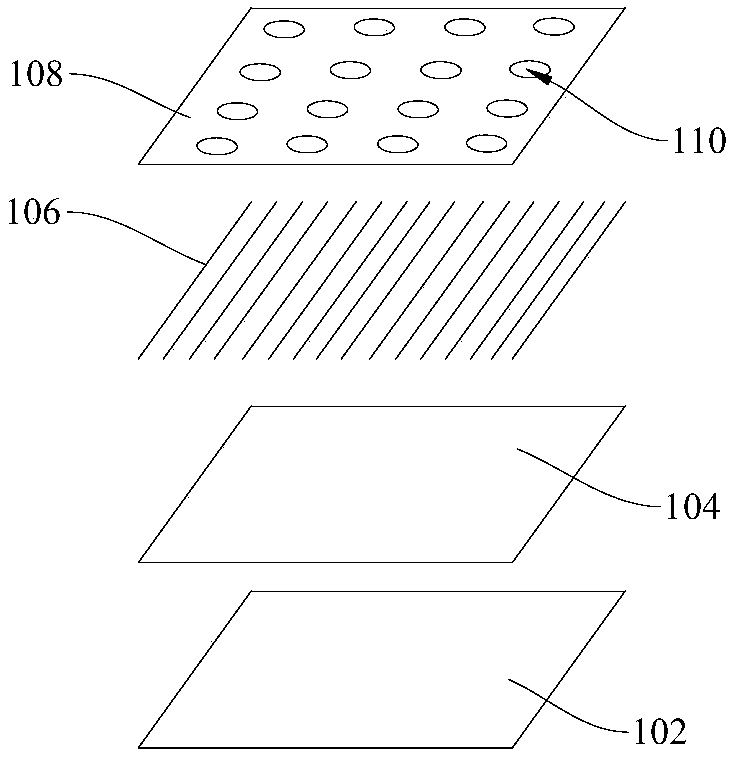

[0035] Please refer to figure 2 , figure 2 Shown is a schematic diagram of...

Embodiment 2

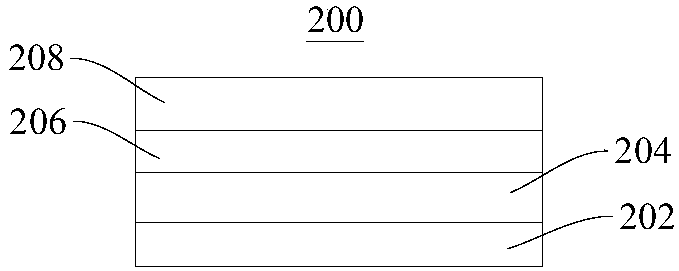

[0048] Please refer to image 3 , image 3 Shown is a schematic structural diagram of the plasma generating assembly 200 provided in this embodiment. This embodiment provides a plasma generating assembly 200, which is mainly used for generating surface glow plasma.

[0049] In this embodiment, the plasma generating assembly 200 includes a power source (not shown in the figure), and a first electrode 202 , an insulating medium 204 , a second electrode 206 , and an insulating layer 208 connected in sequence. The first electrode 202 and the second electrode 206 are respectively connected to the positive pole and the negative pole of the power supply, that is, the first electrode 202 is used as a high-voltage electrode, and the second electrode 206 is used as a ground electrode. The first electrode 202 , the insulating medium 204 , the second electrode 206 , and the insulating layer 208 are tightly bonded in sequence.

[0050] Please refer to Figure 4 , Figure 4 Shown is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com