Dry reaction accelerator with elevated circulating fluid mixing flow

An accelerator, dry technology, used in gas treatment, lighting and heating equipment, chemical instruments and methods, etc., can solve the problems of low desulfurization rate, short waste gas residence time, complex structure desulfurization rate, etc., and achieve the effect of effective reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

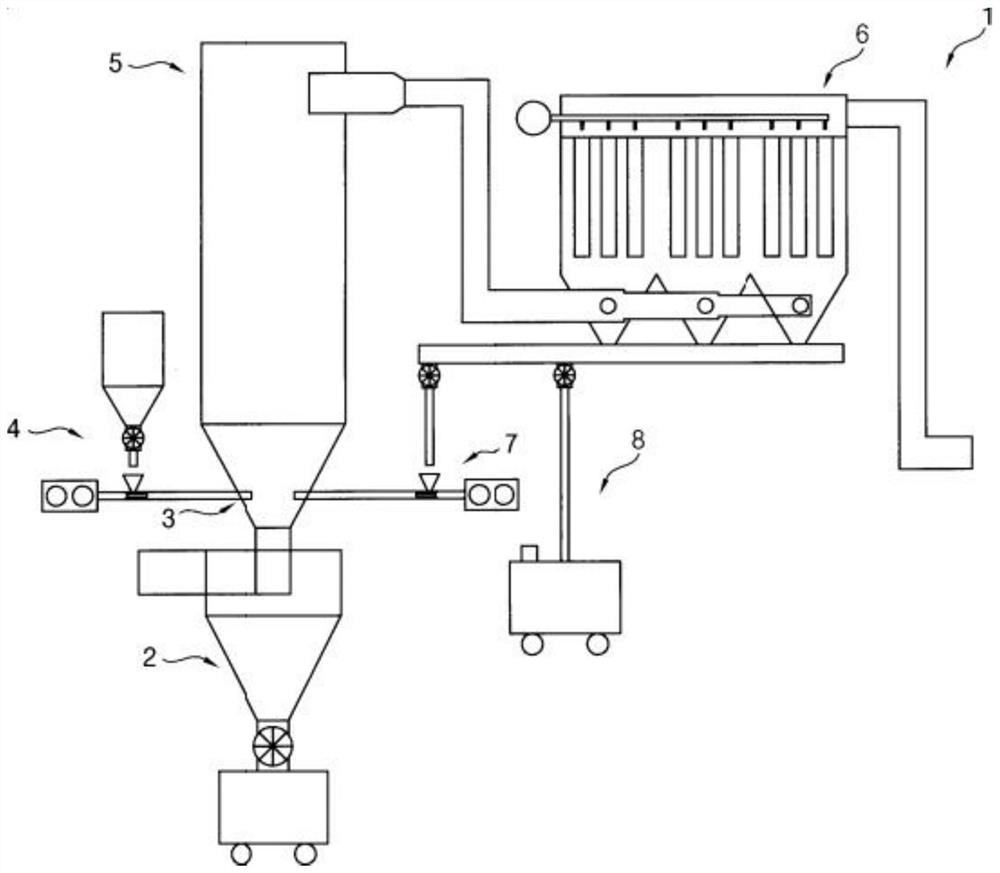

[0035] figure 1 is a schematic diagram showing a conventional dry reaction accelerator.

[0036] see figure 1 , Dry reaction accelerator 1 (Korean Patent No. 10-1617759) includes a cyclone chamber 2, an accelerating part 3, a reactant provider 4, a reaction chamber 5, a filter collection part 6, a reactant re-provider 7 and a particle outlet 8.

[0037] More specifically, the cyclone chamber 2 circulates the incoming exhaust gas to remove particulate matter contained in the exhaust gas. The acceleration part 3 is connected to the upper part of the cyclone chamber 2 , and reactants flow into the acceleration part 3 . The accelerating part 3 accelerates the circulation and rising speed of the exhaust gas to more evenly distribute and diffuse the reactant and the exhaust gas.

[0038] The reactant supplier 4 supplies a reactant to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com