Horizontal well structure for heap precipitation of garbage landfill site and construction method

A technology for a landfill site and a construction method, which is applied in the field of leachate water level control in a landfill site, can solve problems such as difficulty in meeting the water level control requirements of a heap body, achieve good corrosion resistance and deformation resistance, improve work performance, and ensure Feasibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

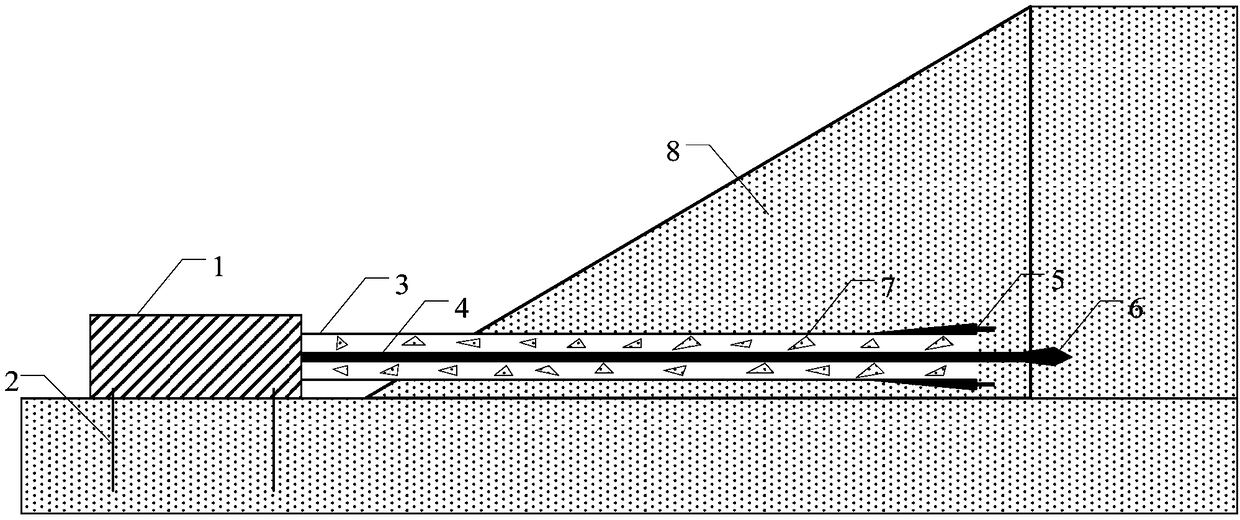

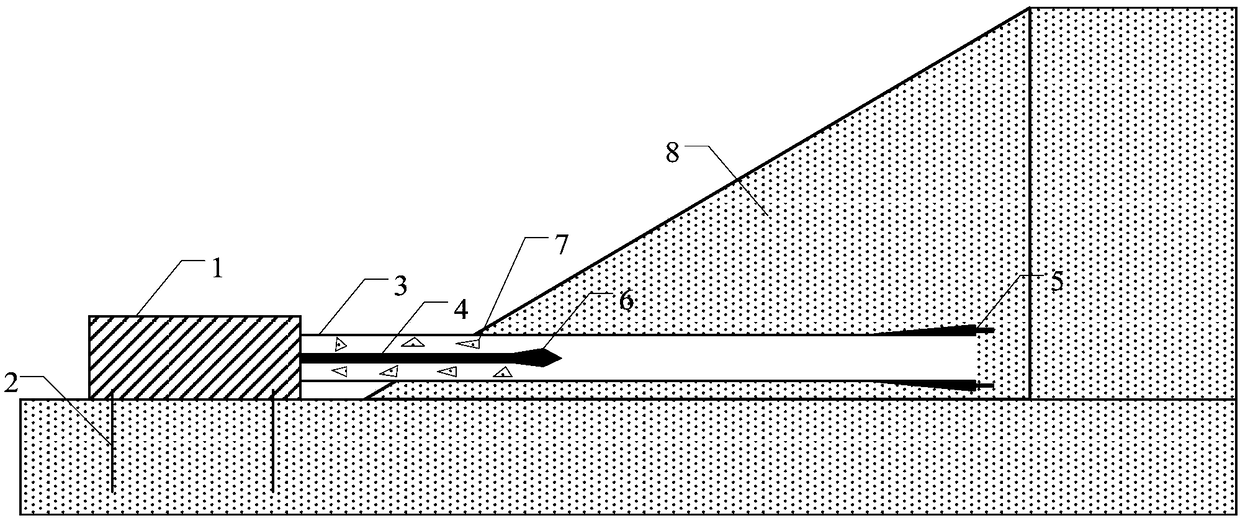

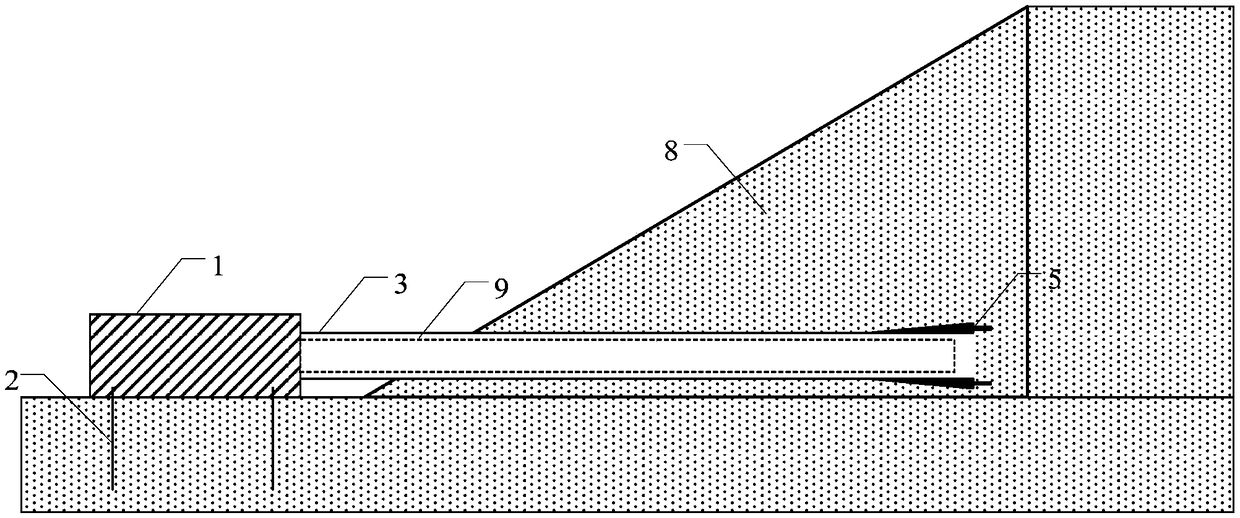

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] The well pipe 9 of the horizontal well of the present invention has a diameter of 133mm and a wall thickness of 6mm; the front section is a galvanized steel pipe without holes, and is used as a negative pressure suction sealing section, and the length is 12m; the middle section has holes in the upper semicircle and no holes in the lower semicircle The galvanized steel pipe, in which the upper semicircle has holes, the hole diameter is 12mm, and the hole rate is 6%. It is used as the leachate inflow surface, and the bottom semicircle has no holes, which is used as the leachate flow channel, and the length is 42m; galvanized steel pipe, the end is sealed with a plug to prevent garbage from entering the well pipe, the length is 3m; the length of a single well pipe is 3m, in order to ensure that the upper semicircle of each well pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com