Dephasing self-coupling zigzag transformer

A zigzagging transformer and transformer technology, applied in the field of transformers, can solve the problems of broken lines, increased transformer loss, large transformer zero-sequence current, etc., and achieve the effects of small no-load current, small no-load loss, and small impedance drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

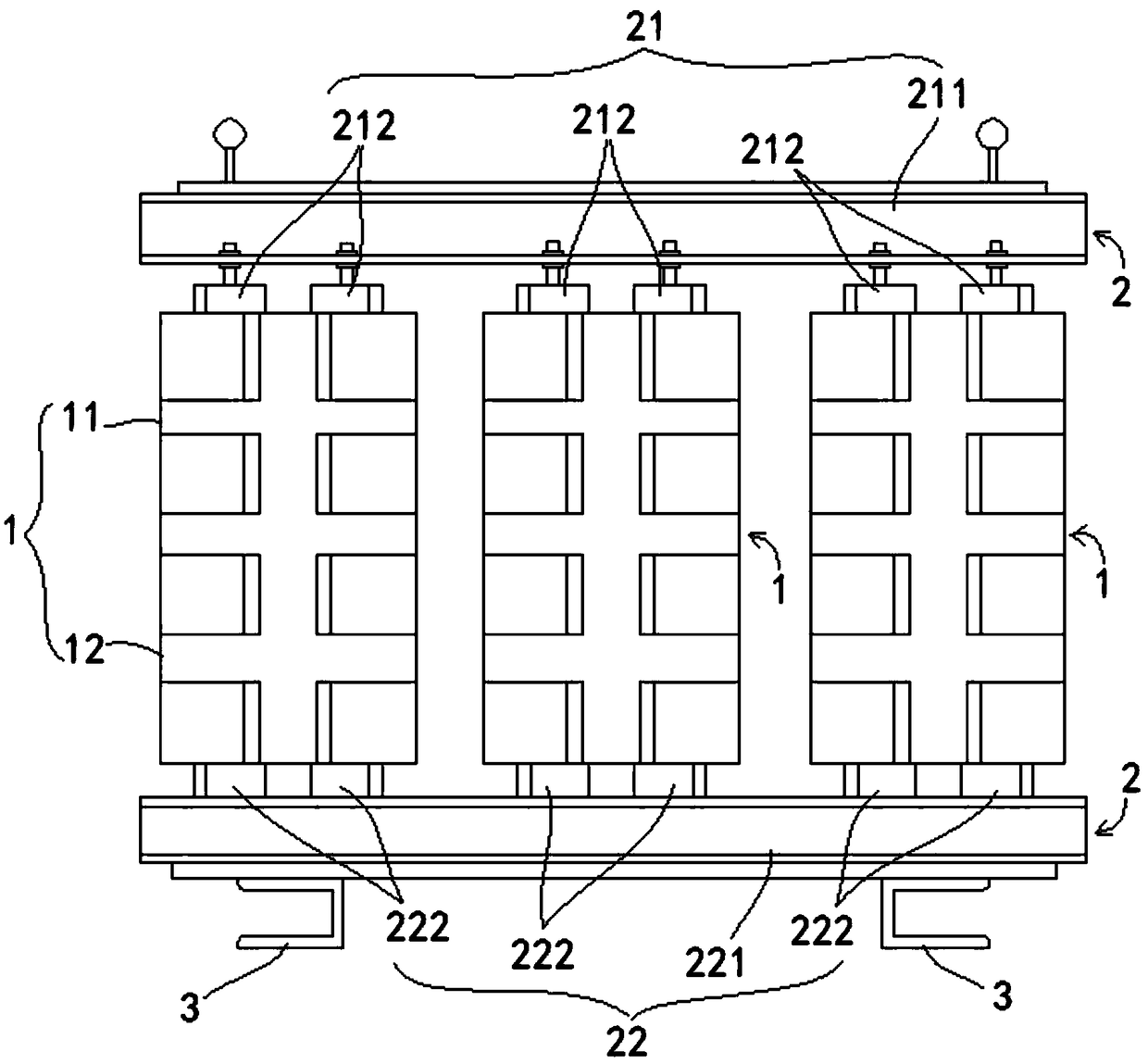

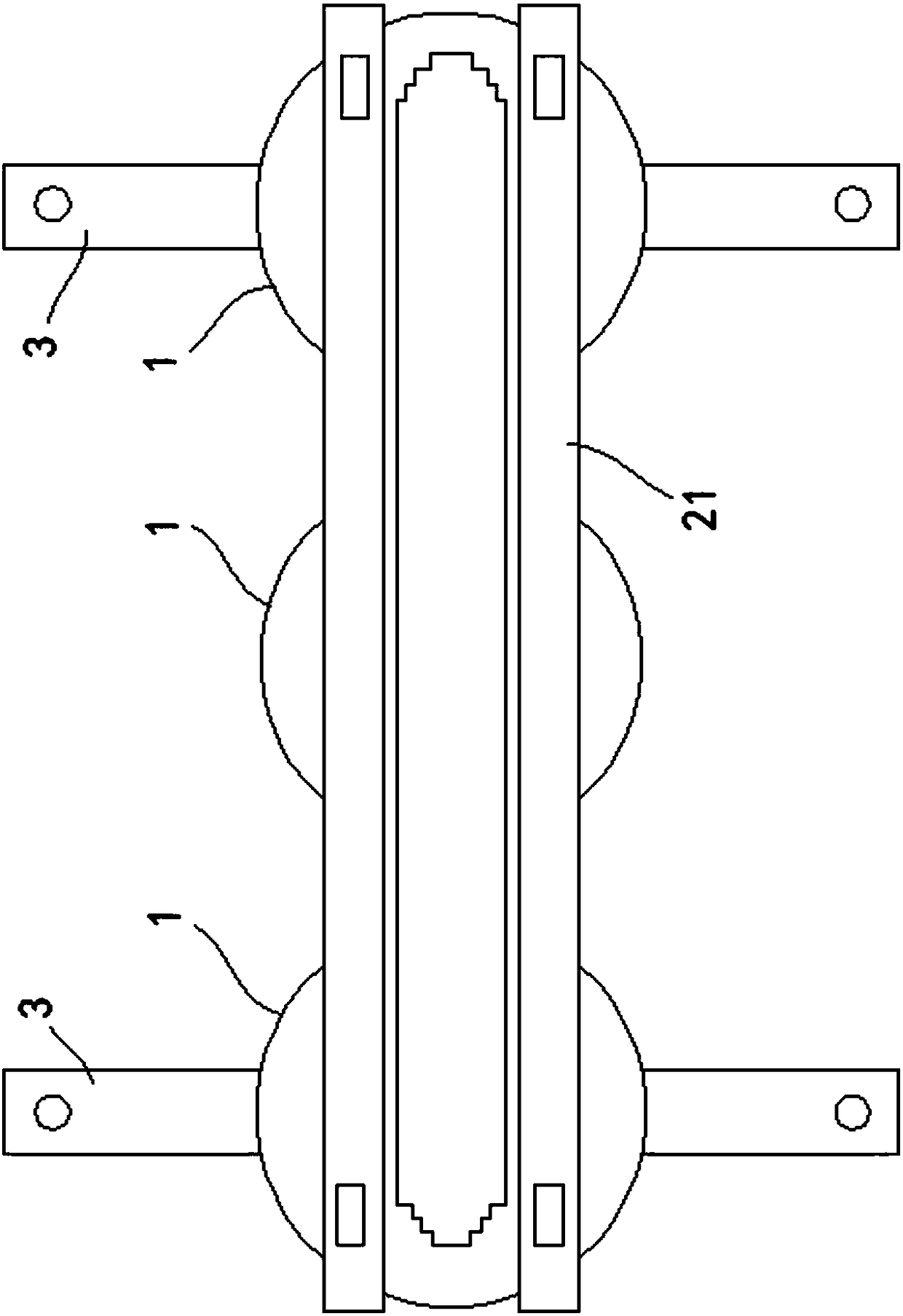

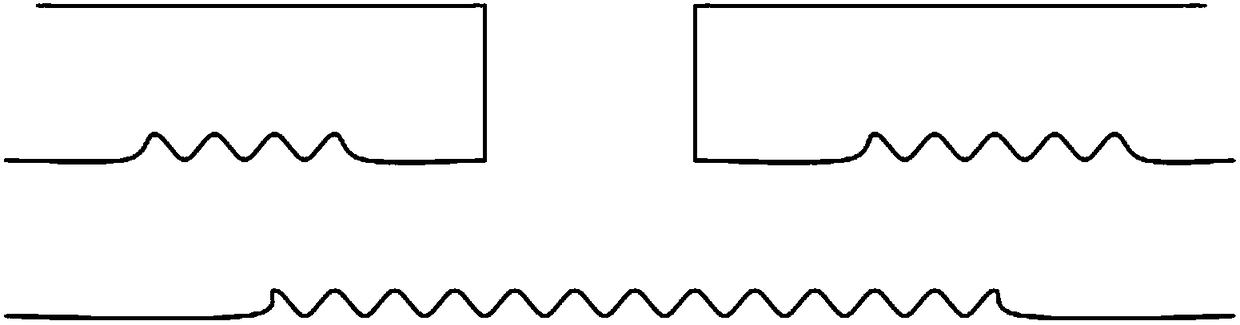

[0042] refer to figure 1 , figure 2 As shown, a phase-shifting auto-coupling transformer is connected with a transformer load and an arc-suppression coil load, including a three-phase high-voltage winding 1, and each phase coil of the high-voltage winding 1 is composed of an upper coil 11 and a lower coil with the same number of turns. Composed of coils 12, the upper coil 11 is set on the upper iron core 21 of the three-phase iron core 2, the lower coil 12 is set on the lower iron core 22 of the three-phase iron core 2, and the upper coil 11 is The main winding with voltage regulating tap, the lower coil 12 is a phase shifting winding with a phase shifting effect, and the phase shifting winding and the voltage regulating winding have a phase relationship of 60° on each phase.

[0043] Each phase coil of the high-voltage winding 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com