Nanowire-like MnO2 material for supercapacitor and preparation method and application thereof

A technology of supercapacitors and nanowires, applied in the manufacture of hybrid/electric double layer capacitors, electrodes of hybrid capacitors, etc., can solve the problems of inability to meet the requirements of supercapacitors on electrode materials, poor cyclability of manganese dioxide, performance degradation, etc. The effect of good ion transport performance and storage performance, simple preparation process and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] First, the muffle furnace was raised from room temperature to 350 °C, and then 5 g NaNO 3 Put it into the muffle furnace and keep it warm for 10min, so that the NaNO 3 melted, then 0.1gMnCl 2 Mix with 0.04g graphite nanofiber GNFs and ball mill evenly, then add molten NaNO 3 , stir evenly to make the reaction complete, keep warm for 1-2min, cool to room temperature naturally, wash, centrifuge, and dry to obtain nanowire-like MnO 2 Material.

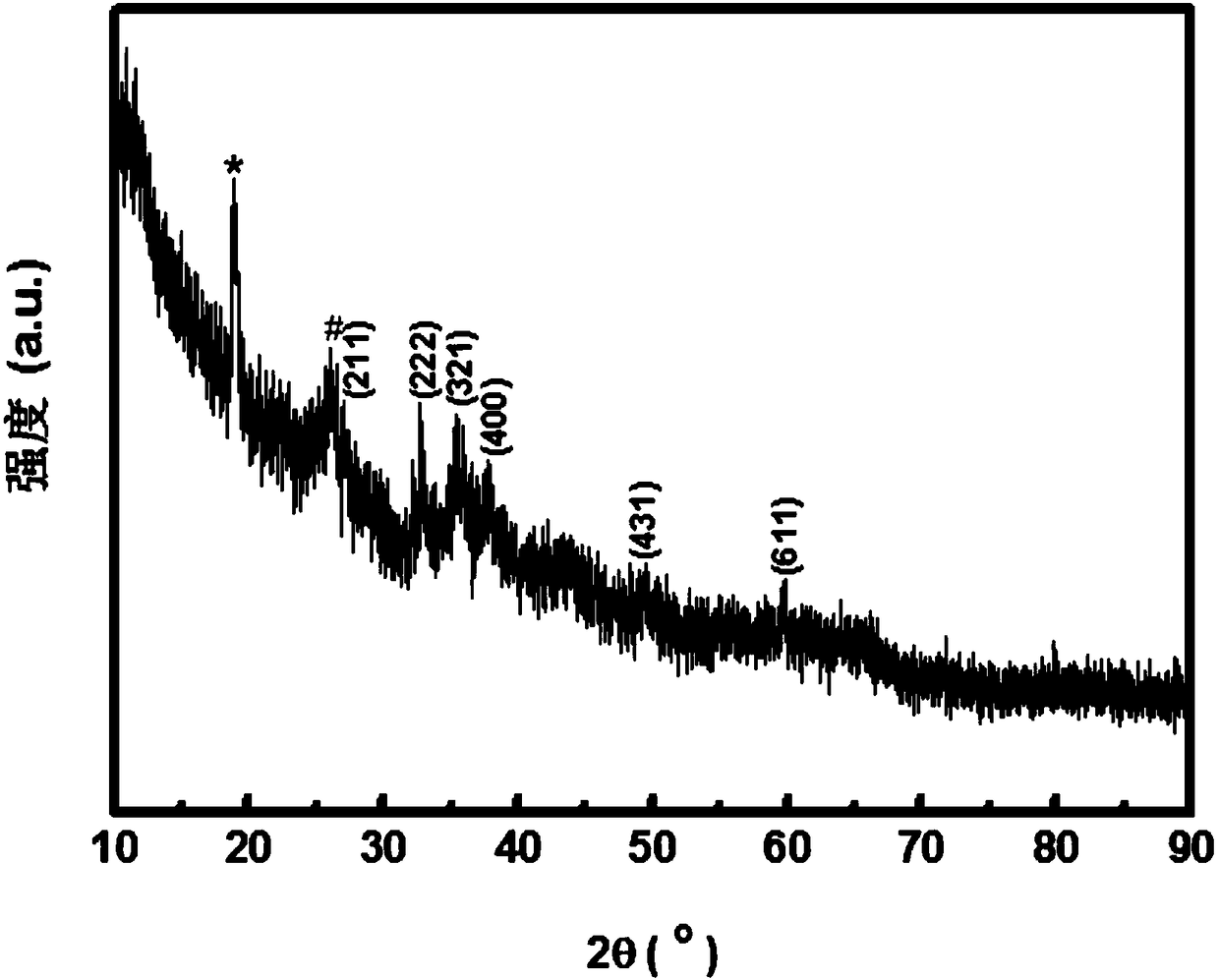

[0024] The aforementioned nanowire-like MnO 2 The XRD spectrum of the material is as figure 1 Shown, wherein, (211), (222), (321), (400), (431), (611) is Mn 2 o 3 The characteristic peaks correspond to the standard card JCPDS No. 10-0069, where * is MnO 2 The (111) characteristic peak. As can be seen from the XRD pattern, MnO 2 The characteristic peaks are sharp sharp peaks, indicating that MnO 2 The degree of crystallization is better and the material purity is higher.

[0025] The aforementioned nanowire-like MnO 2 Th...

Embodiment 2

[0029] First, the muffle furnace was raised from room temperature to 300 °C, and then 5 g NaNO 3 Put it into the muffle furnace and keep it warm for 10min, so that the NaNO 3 melted, then 0.1gMnCl 2 Mix with 0.004g graphite nanofiber GNFs and ball mill evenly, then add molten NaNO 3 , keep warm for 1-2min, cool naturally to room temperature, wash, centrifuge, and dry to obtain nanowire-like MnO 2 material, in the form of nanowires.

[0030] The nanowire-like MnO 2 The material has electrical properties equivalent to that of Example 1 and is suitable for supercapacitors.

[0031] In summary, the MnO provided by the invention 2 The material is nanowire-like in shape, has a large specific surface area and a regular microstructure, which is conducive to the adsorption and transport of electrons, so it has better electrochemical activity and can be applied to supercapacitors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com