A kind of preparation method of anti-reflection film for three-junction solar cell for flexible space

A technology of anti-reflection film and solar cell, which is applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as differences and lack of clear guiding significance for ion source parameters, increase aggregation density and firmness, and save heating and cooling , save the effect of the operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The implementation of this application will be described in detail below with the accompanying drawings and embodiments, so as to fully understand and implement the implementation process of how this application uses technical means to solve technical problems and achieve technical effects.

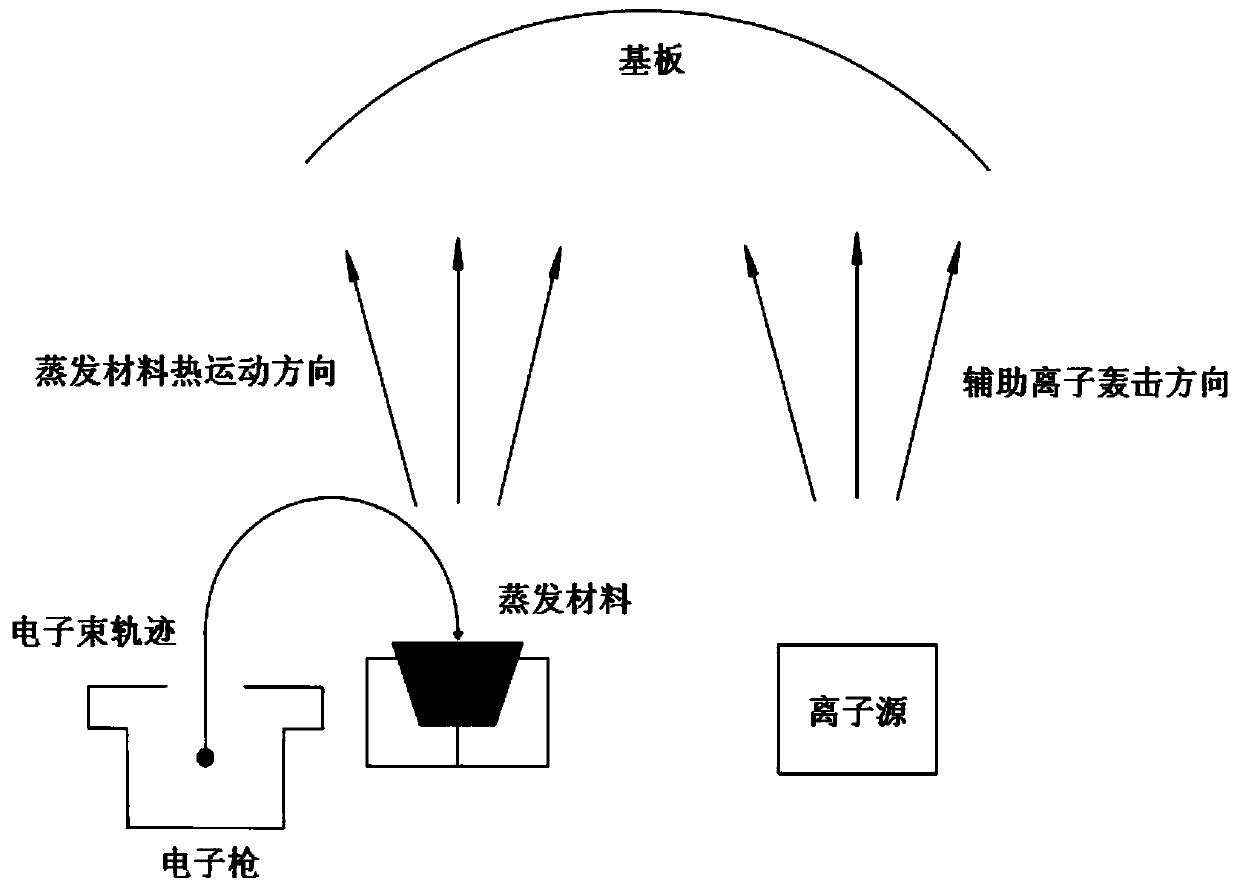

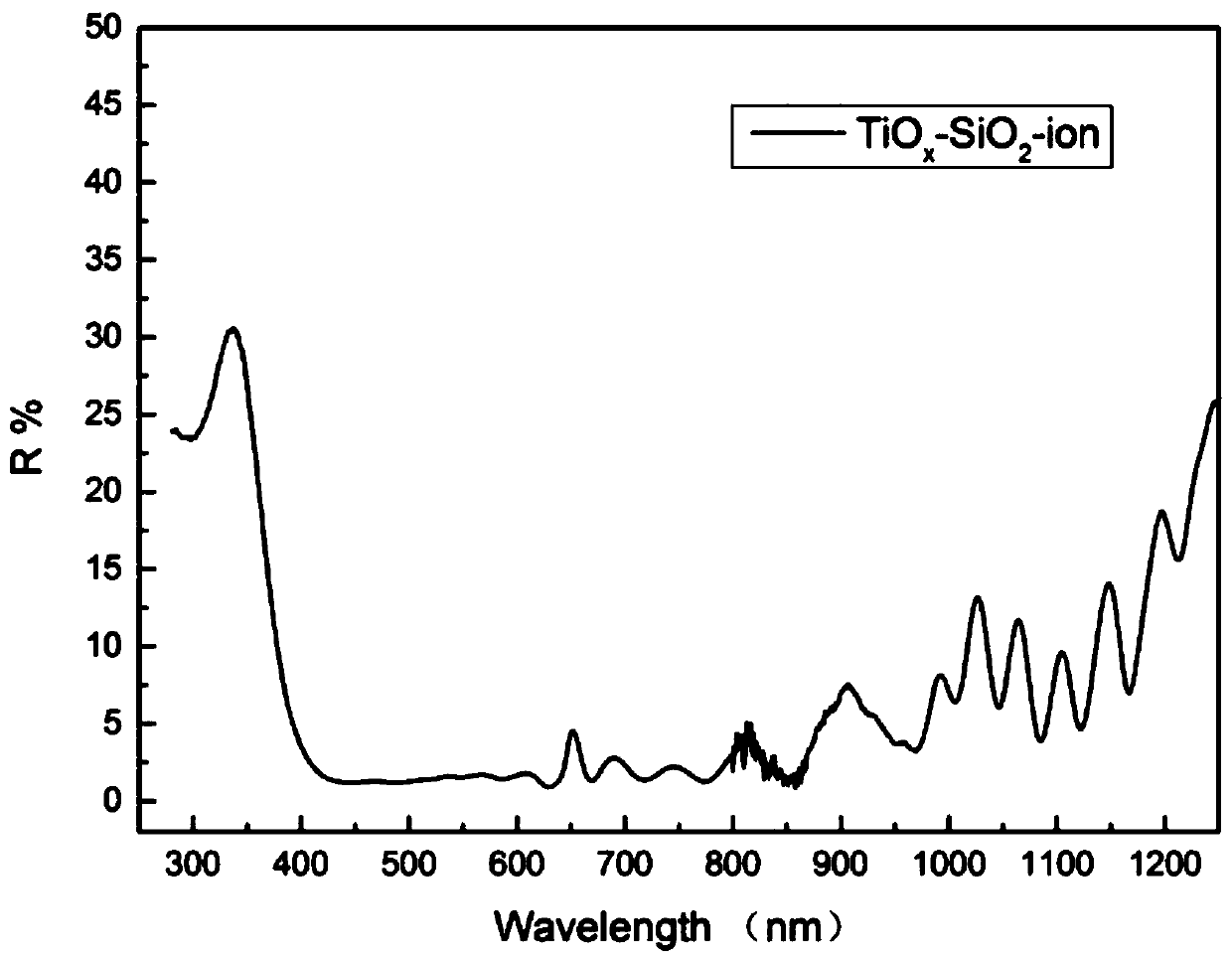

[0024] The invention adopts the anti-reflection film deposition technology combining electron beam thermal evaporation and ion source assisted deposition to prepare the anti-reflection film at normal temperature.

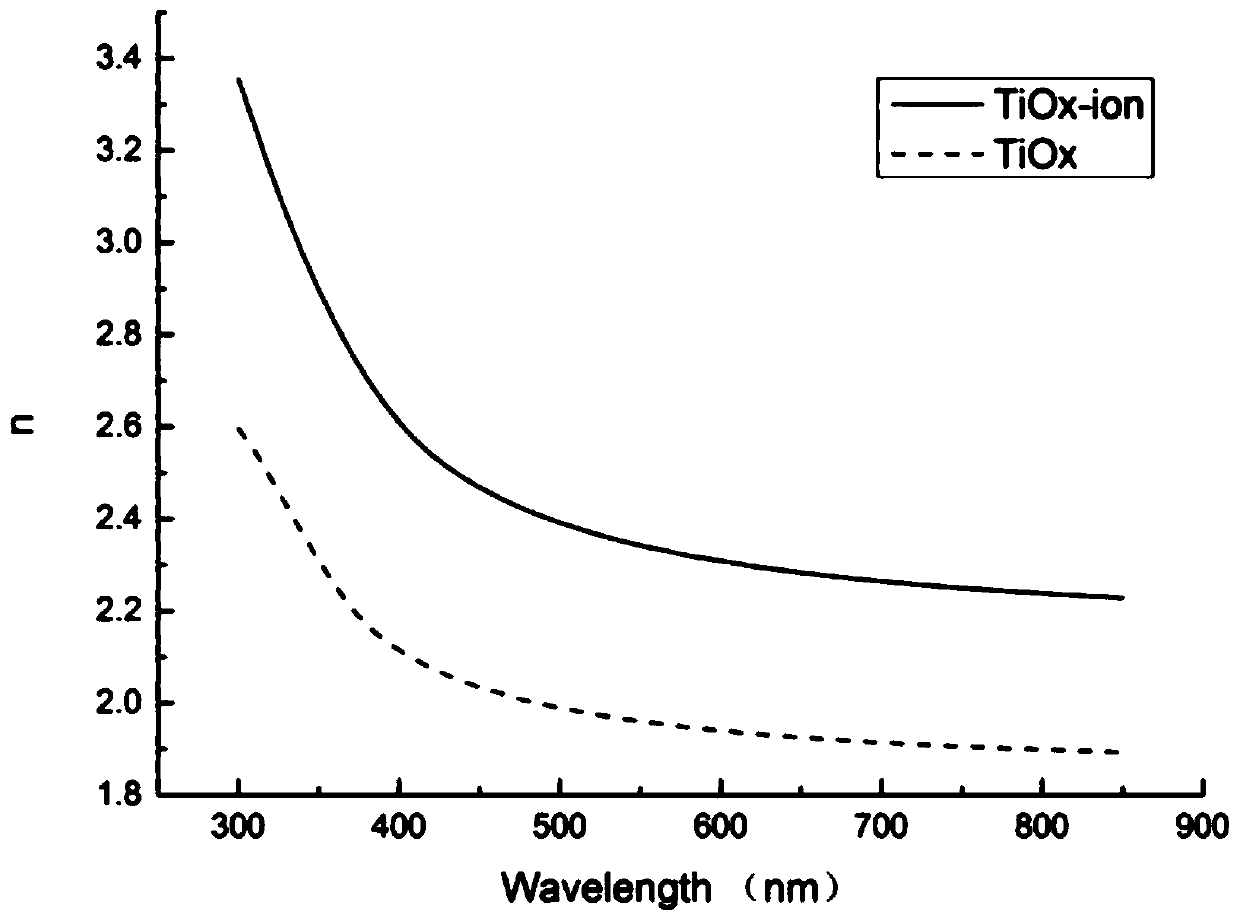

[0025] Ion Source Assisted Deposition (IAD) is an effective assisted deposition technology. When the film material is heated and evaporated, the film material particles are continuously bombarded by the energetic particles from the ion source on the surface of the substrate. Through momentum transfer, the bombardment particles provide sufficient kinetic energy for the film material particles, which improves the mobility of the film material particles, increases the aggregatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com