Hybrid power car electric speedup clutch and control method thereof

A hybrid vehicle and clutch technology, which is applied to the arrangement of multiple different prime movers of mechanically driven drum brakes, power units, and general power units, can solve the problems of small power, insufficient axial space, and shortage of vehicle models. To achieve the effect of controllable clutch braking force, easy operation and adjustment, and simplified overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

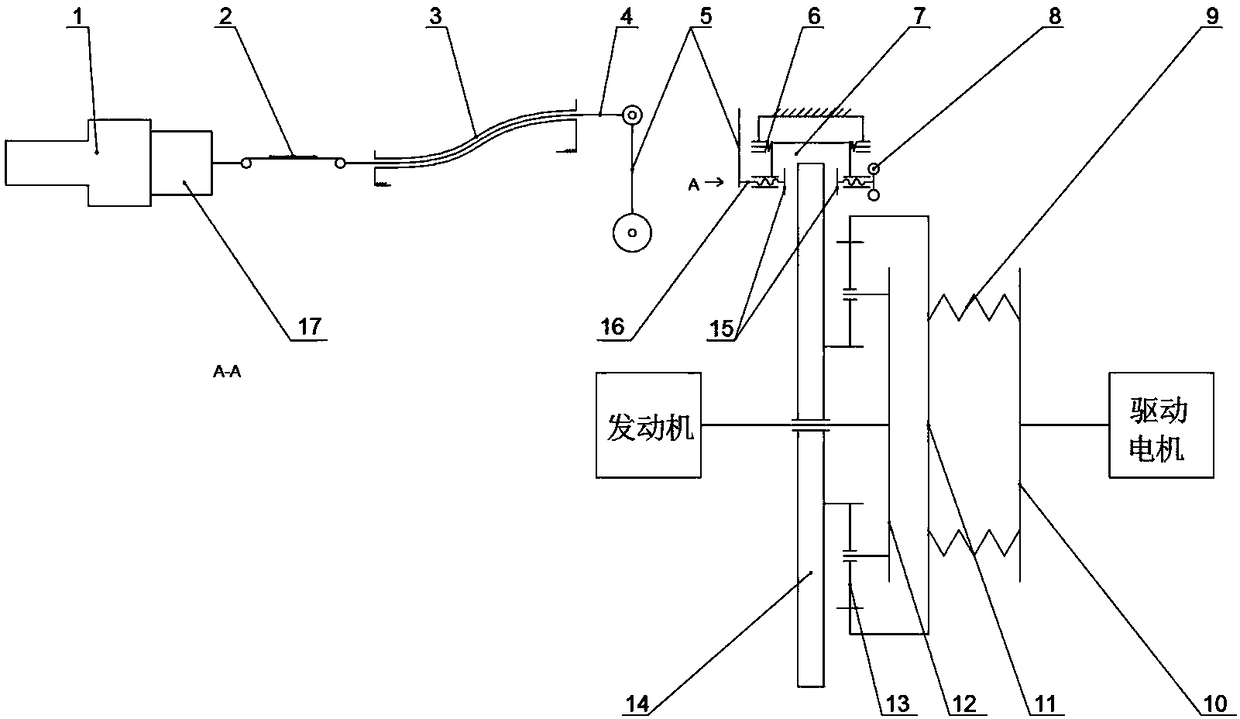

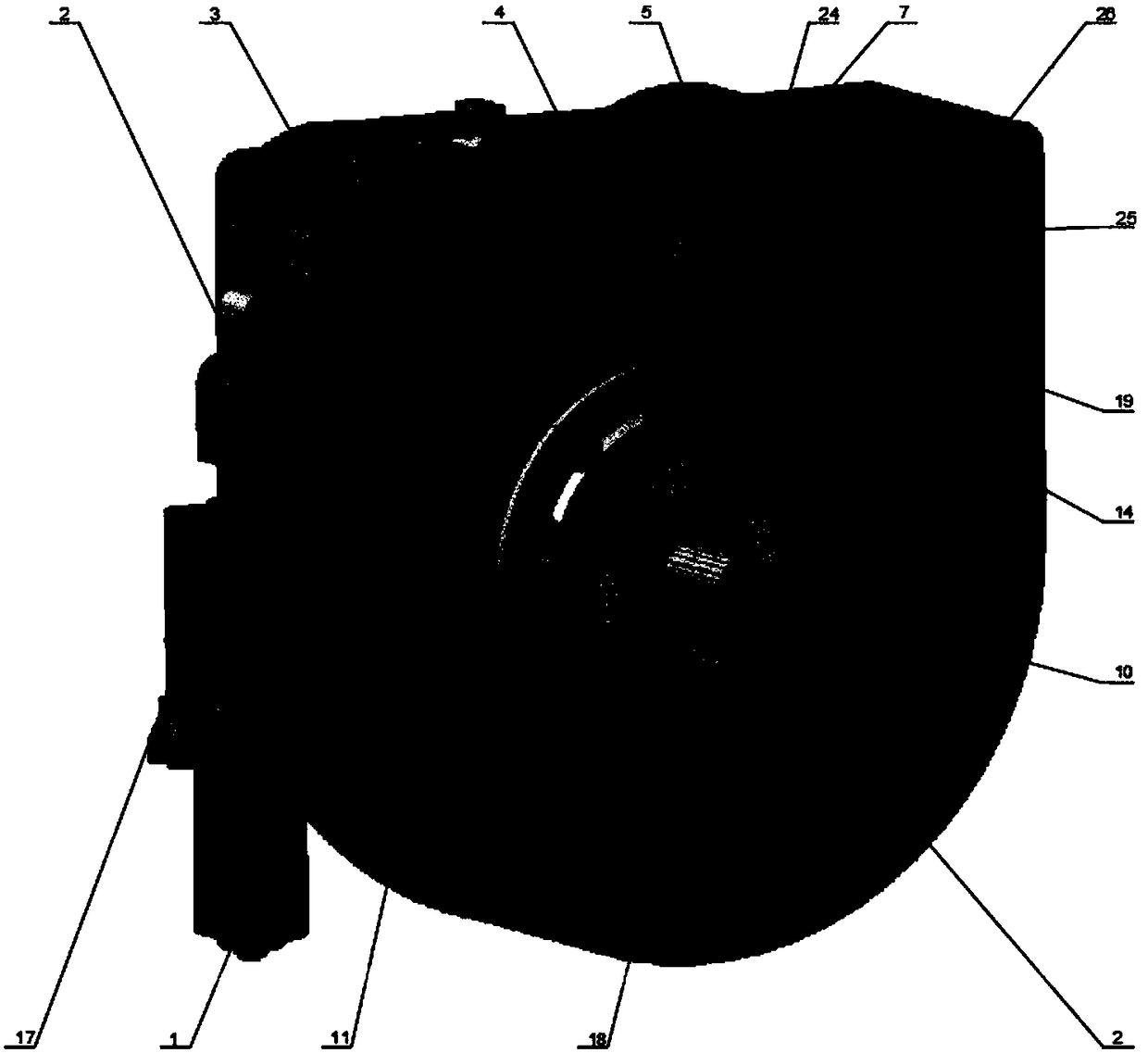

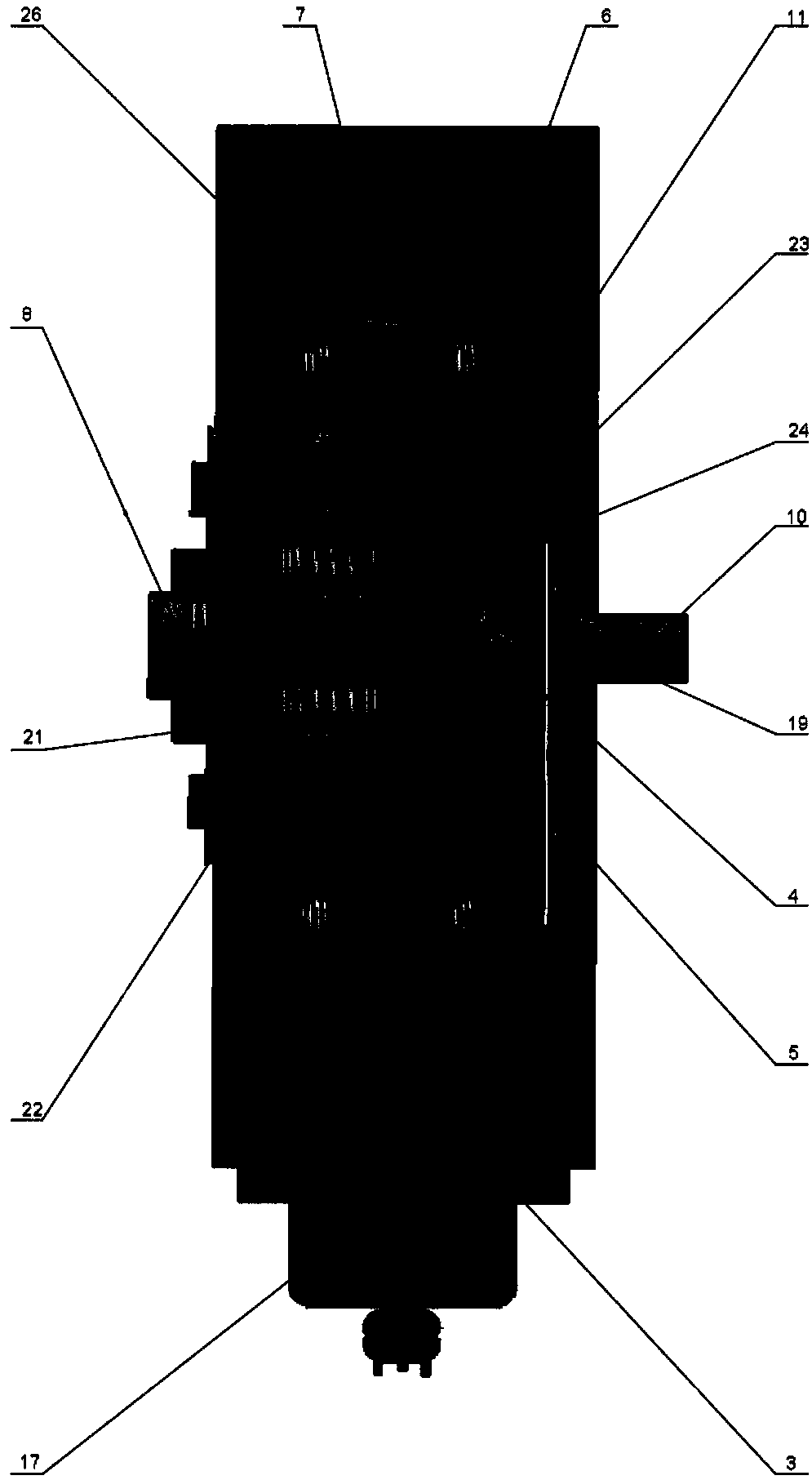

[0026] The present invention will be further described below in conjunction with accompanying drawing:

[0027] Such as figure 1 , 2 , 3, the present invention mainly includes a reduction motor 1, a screw nut mechanism 17, a housing 26, a brake caliper assembly, and a planetary gear train assembly. Install the planetary gear train assembly that is made up of sun gear 14, planetary gear 13, planetary carrier 12, outer ring gear 11; Figure 4 , 5 As shown, the sun gear is fixed on the shaft of the planetary carrier through the bearing, the planetary gear is fixed on the planetary carrier through the shaft and the bearing, the planetary carrier is embedded in the outer ring gear, and the planetary gear meshes with the sun gear and the outer ring gear respectively; The inner rotating hub 10 and the shock absorber housing 18 are provided in turn, and the shock absorber housing is fixed on the outer ring gear by bolts, and the inner rotating hub 10 is clamped between the shock ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com