Cooling equipment for automobile pig iron smelting

A technology of cooling equipment and pig iron, which is applied in the field of cooling equipment for automobile pig iron smelting, which can solve the problems of large solid particles, achieve the effect of smaller inter-molecular distance, better condensation effect and lower cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is further described in detail through specific implementation methods:

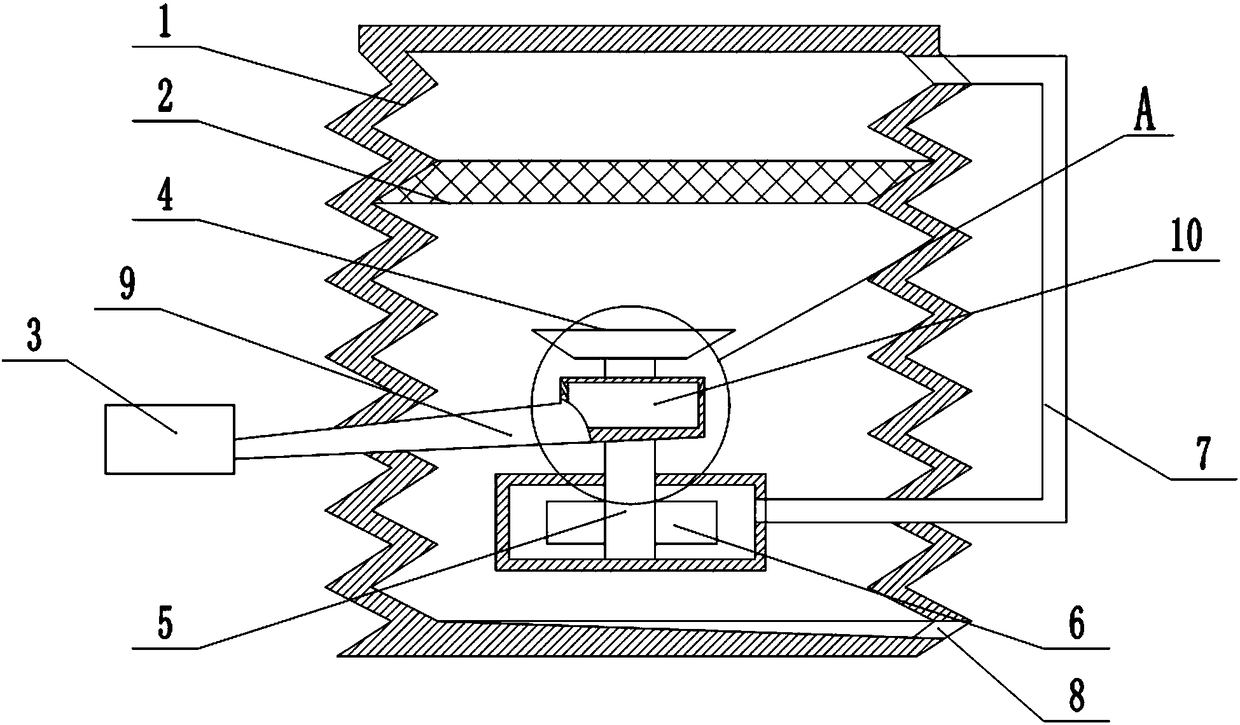

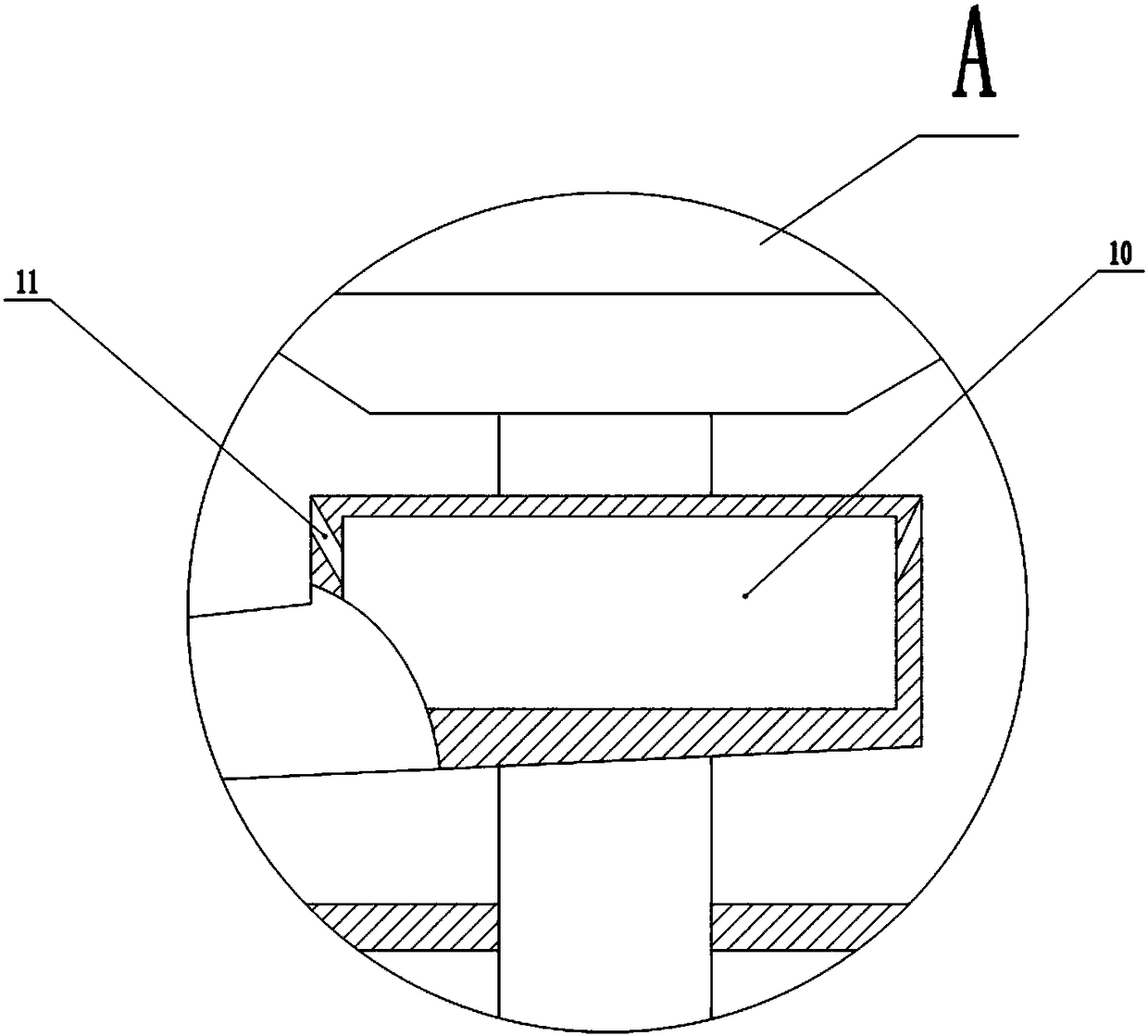

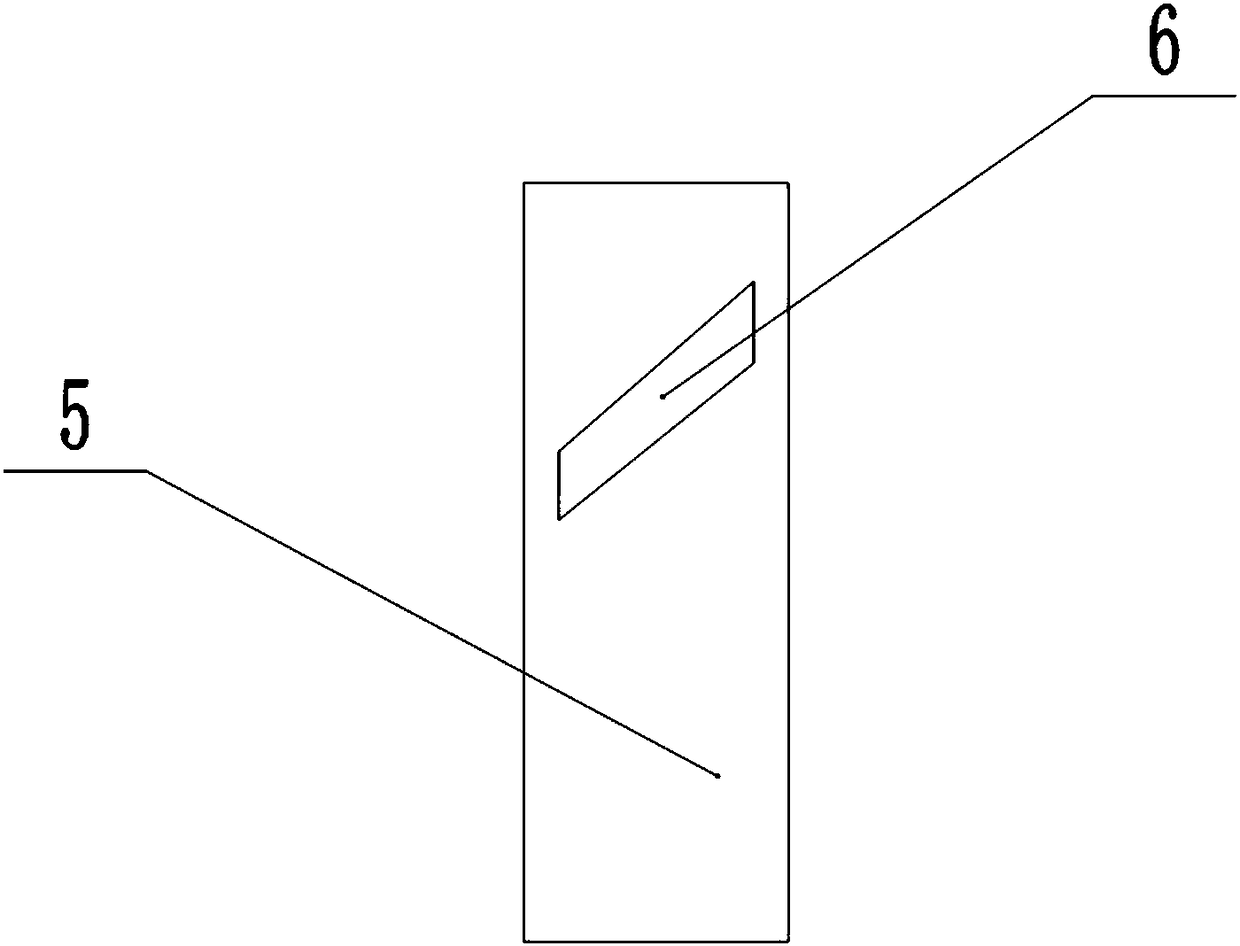

[0024] The reference signs in the drawings of the description include: cooling chamber 1, filter plate 2, fan 3, disk 4, rotating shaft 5, blade 6, guide pipe 7, discharge port 8, air inlet pipe 9, second air box 10, Guide hole 11.

[0025] Such as figure 1 As shown, the cooling equipment for automobile pig iron smelting includes a frame. A cooling chamber 1 is arranged on the frame. The upper and lower ends of the cooling chamber 1 are sealed. The bottom of the right side wall of the cooling cavity 1 is provided with a discharge port 8 , and the outlet of the material guide groove is facing the discharge port 8 . The frame is located outside the cooling cavity 1 and is provided with a longitudinal limiting groove, the top of the cooling cavity 1 is fixed on the top of the limiting groove, the bottom of the cooling cavity 1 is fixed on the bottom of the limiting groove, and the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com