Method for removing metal impurity cobalt from crude zinc raw materials to obtain zinc-containing solution

A technology of impurity metal and solution, applied in the field of purification process of zinc liquid, can solve the problems of burning the electrode plate, time-consuming and energy-consuming, and high cost, and achieve the effects of simple environmental protection, simple process control and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

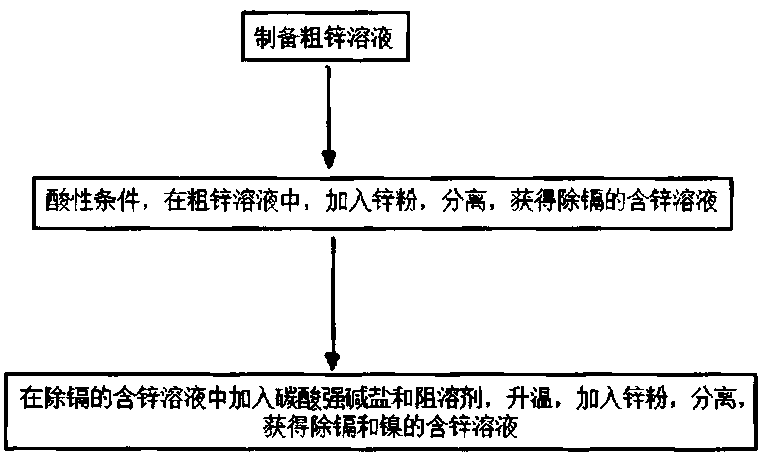

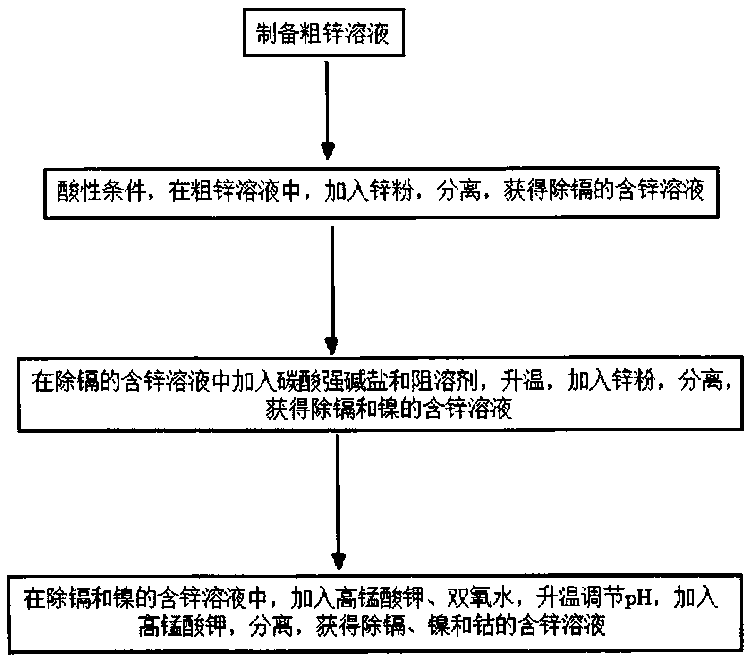

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, the sub-zinc oxide volatilized by the steel mill is used as the crude zinc raw material. It contains 4.0wt% cadmium, 2.0wt% nickel, and 1.8wt% cobalt, and 3.2wt% iron.

[0048] Add 1290 kg of crude zinc raw material to 3870 kg of recycled washing water, add concentrated sulfuric acid (98℅), participate in the reaction, and the concentration of sulfuric acid is about 50wt℅ after entering the kettle, let it fully react, leaching and dissolving, and then filter A crude zinc solution is obtained.

[0049] Place the resulting crude zinc solution in 15 M 3 Volume replacement reactor. Start stirring, and at normal temperature, add 15kg of metal zinc powder to prevent cadmium sulfate from interfering with the subsequent separation. Sponge cadmium is precipitated, and a rough zinc solution for preliminary cadmium removal is obtained. After the sponge cadmium is precipitated, the nickel concentration in the solution is 0.015g / L, add 40 kg of potassium carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com