Radiation-proof thermal-insulation glass and preparation method thereof

A heat-insulating glass and radiation-proof technology, which is applied in the direction of sputtering plating, ion implantation plating, metal material coating technology, etc., can solve the problem of uneven distribution of indium tin oxide particles, poor barrier of radiation-proof heat-insulating glass, oxidation Indium tin particles are easy to agglomerate and other problems, to achieve the effect of enhancing dispersion, reducing sedimentation, and enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

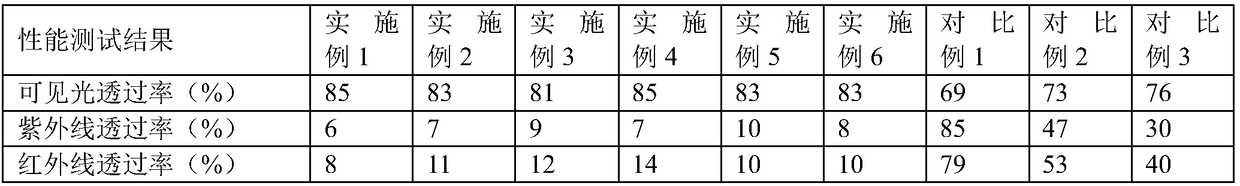

Examples

Embodiment 1

[0035] Premixing: Put 86kg of polycarbonate particles into the reactor, raise the temperature of the reactor to 277°C, stir evenly until the polycarbonate particles melt, then slowly add 7kg of octadecyltrimethoxysilane into the reactor , 7kg of octyltrimethoxysilane, and continue to stir evenly for 17min to obtain a premixed product;

[0036] Molding: Pour the premixed product into a mold, and press it into a polycarbonate glass plate of 1m×1m×1cm;

[0037] Cleaning: After the polycarbonate glass plate is ultrasonically cleaned with deionized water, continue to use absolute ethanol to ultrasonically clean it. After cleaning, dry the surface of the polycarbonate glass plate;

[0038] Vacuuming: place the cleaned polycarbonate glass plate in the magnetron sputtering equipment, and then vacuumize;

[0039] Filling with working gas: fill the magnetron sputtering equipment with argon and oxygen, wherein the volume ratio of argon to oxygen is 40:1, adjust the internal pressure of ...

Embodiment 2

[0043] Premixing: Put 80kg of polycarbonate particles into the reactor, raise the temperature of the reactor to 272°C, stir evenly until the polycarbonate particles melt, then slowly add 5kg of octadecyltrimethoxysilane into the reactor , 9 kg of octyltrimethoxysilane, and continue to stir evenly for 19 minutes to obtain a premixed product;

[0044] Molding: Pour the premixed product into a mold, and press it into a polycarbonate glass plate of 1m×1m×1cm;

[0045] Cleaning: After the polycarbonate glass plate is ultrasonically cleaned with deionized water, continue to use absolute ethanol to ultrasonically clean it. After cleaning, dry the surface of the polycarbonate glass plate;

[0046] Vacuuming: place the cleaned polycarbonate glass plate in the magnetron sputtering equipment, and then vacuumize;

[0047] Filling with working gas: fill the magnetron sputtering equipment with argon and oxygen, wherein the volume ratio of argon to oxygen is 40:1, adjust the internal pressu...

Embodiment 3

[0051] Premixing: Put 92kg of polycarbonate particles into the reactor, raise the temperature of the reactor to 272°C, stir evenly until the polycarbonate particles melt, then slowly add 5kg of octadecyltrimethoxysilane into the reactor , 9 kg of octyltrimethoxysilane, and continue to stir evenly for 15 minutes to obtain a premixed product;

[0052] Molding: Pour the premixed product into a mold, and press it into a polycarbonate glass plate of 1m×1m×1cm;

[0053] Cleaning: After the polycarbonate glass plate is ultrasonically cleaned with deionized water, continue to use absolute ethanol to ultrasonically clean it. After cleaning, dry the surface of the polycarbonate glass plate;

[0054] Vacuuming: place the cleaned polycarbonate glass plate in the magnetron sputtering equipment, and then vacuumize;

[0055] Filling with working gas: fill the magnetron sputtering equipment with argon and oxygen, wherein the volume ratio of argon to oxygen is 40:1, adjust the internal pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com