Method of production of high-pressure seamless cylinder from corrosion-resistant steel

A seamless gas cylinder, corrosion-resistant steel technology, applied in the field of material forming, can solve the problems of complex handling, storage and transportation, low strength, high quality, etc., and achieve the effect of material saving, low quality and reduced quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

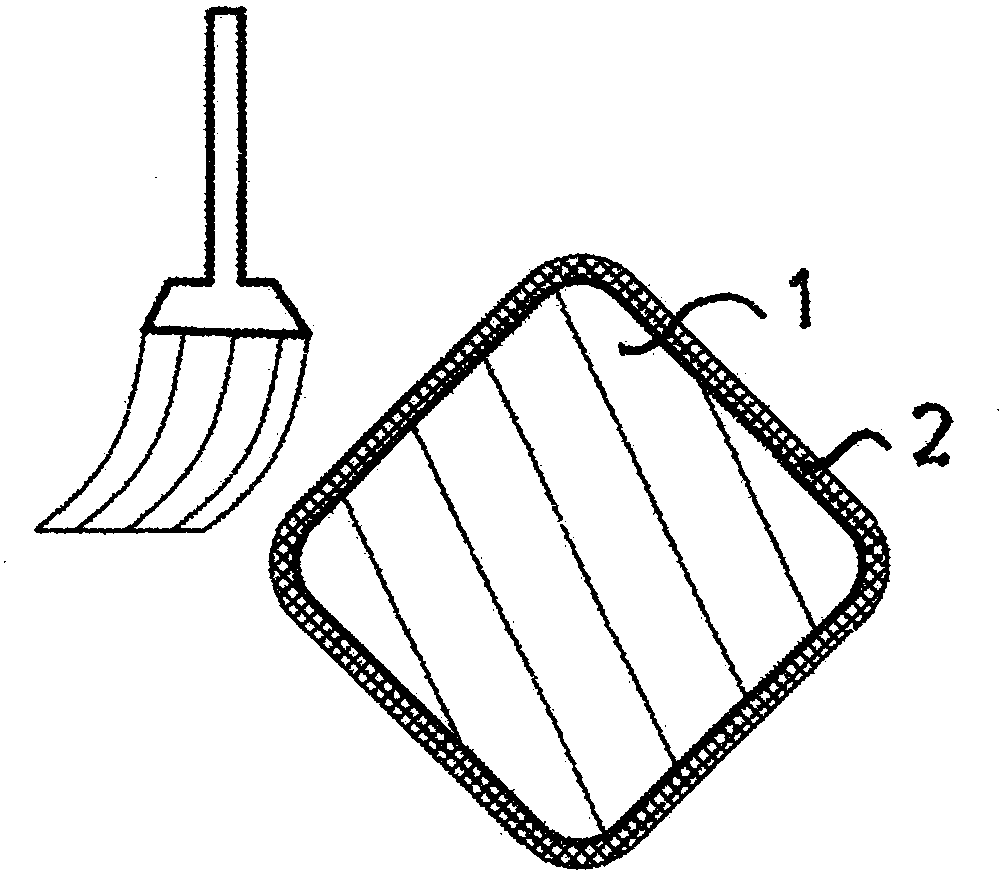

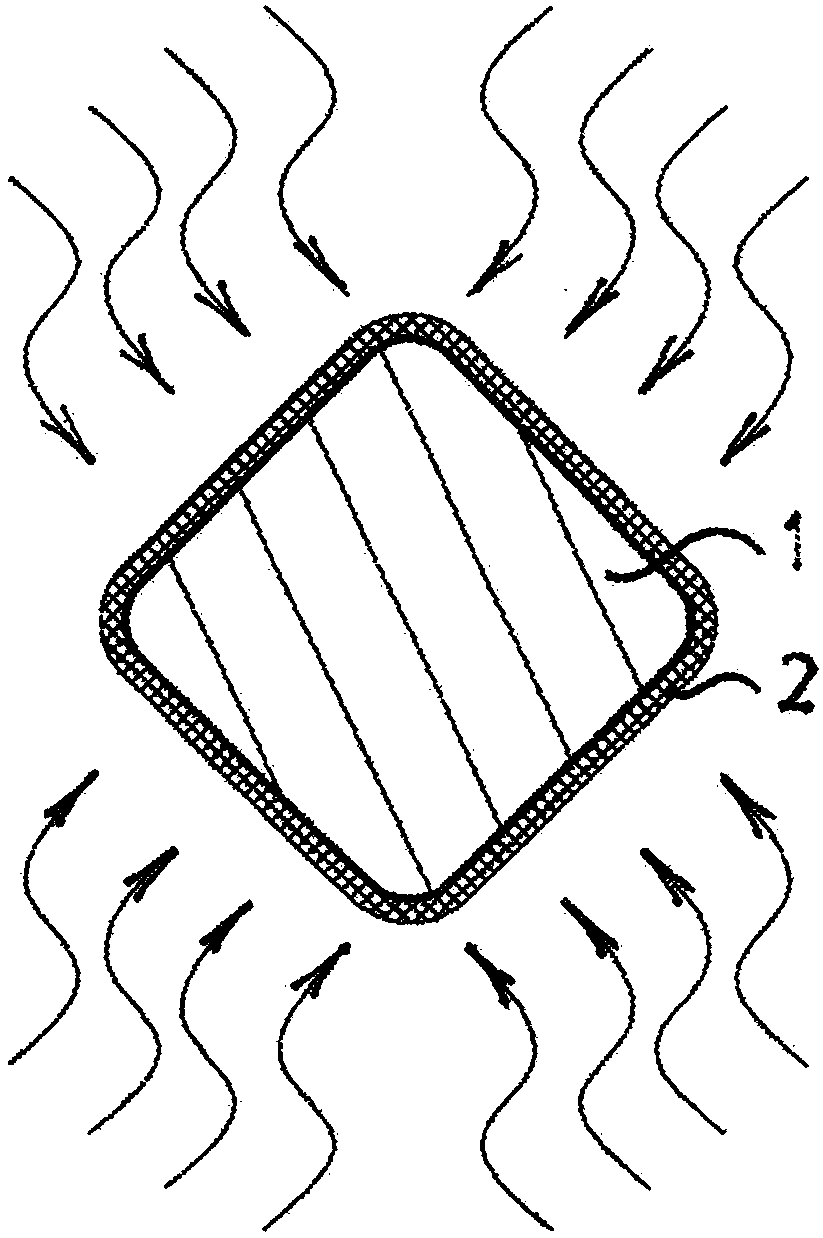

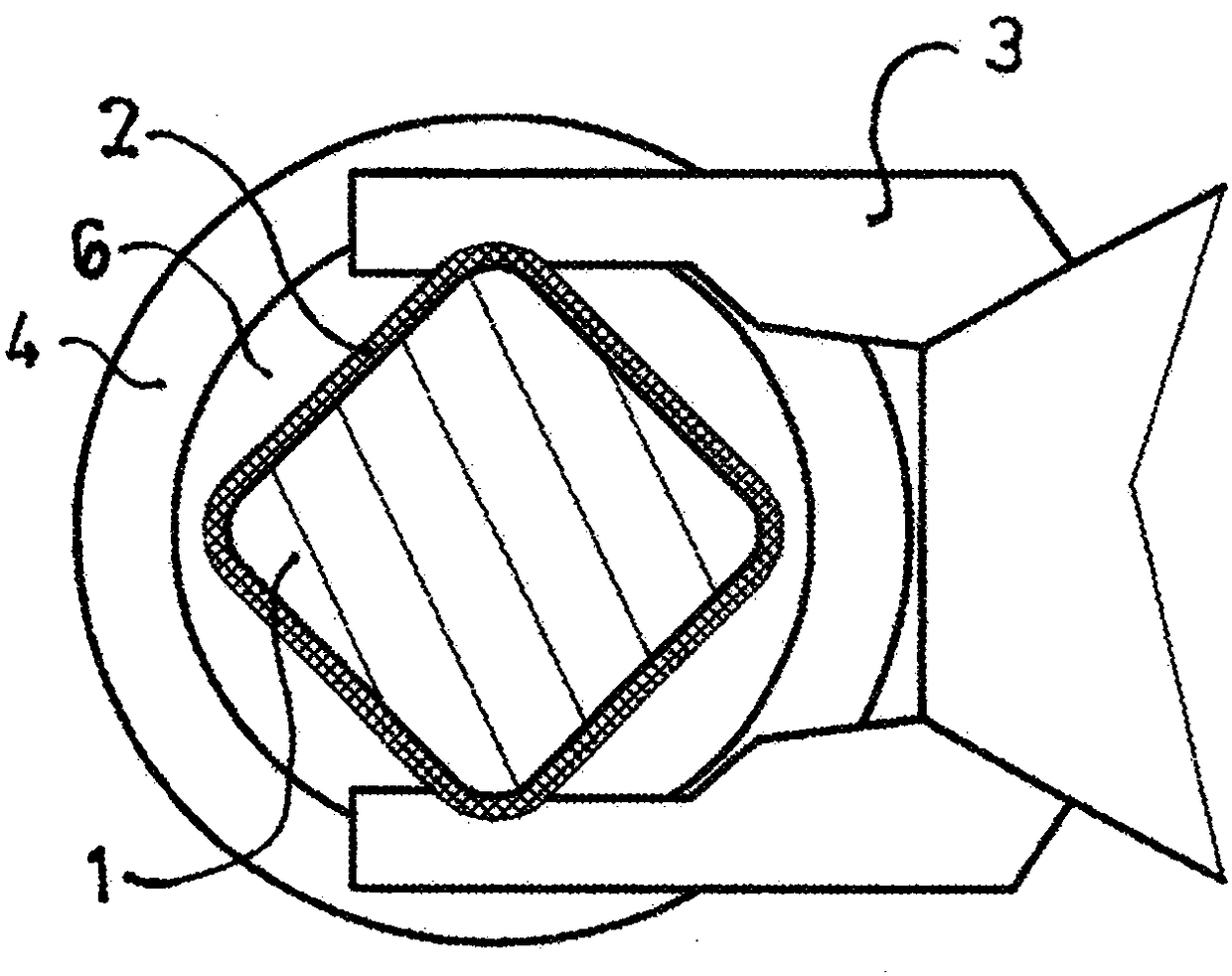

[0018] with the help of Figure 1 to Figure 4 And the production method of corrosion-resistant high-pressure seamless gas cylinders for the storage, transportation and use of natural gas described below diagrammatically shows an example of an embodiment of the present invention.

[0019] Parts of the dimensions required to manufacture gas cylinders with a production volume are first cut from a strip of corrosion-resistant steel billet with a square or circular cross-section. Each individual component, the starting steel blank 1 , is coated on at least 85% of its surface with a coating 2 of a material based on water glass. The thickness of the applied layer is 20 μm to 150 μm. Suspensions commonly referred to as water glass are used as water glass-based material. For the purposes of the present invention, a suspension based on water glass means a suspension comprising 20% to 40% by weight of sodium or potassium silicate or a mixture thereof and 80% to 40% by weight of water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com