Control system for synthesizing nickel carbonyl through continuous carbonylation

A technology of control system and chemical synthesis, applied in the direction of general control system, control/regulation system, carbonyl nickel, etc., can solve the problem of low reliability of individual controllers, and achieve the effect of high reliability, simple use and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

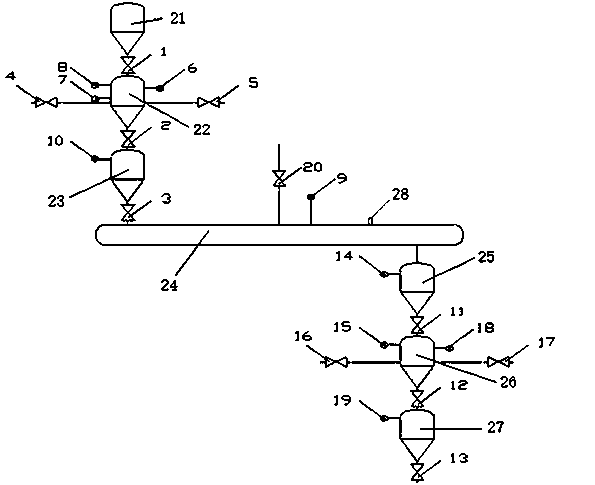

[0011] The present invention will be further described below in conjunction with accompanying drawing.

[0012] see figure 1 , a kind of control system of continuous carbonylation of nickel carbonyl of the present invention, the control system controls the production device of continuous carbonylation of nickel carbonyl through PLC logic chain program to realize automatic operation; the production device includes storage materials connected in sequence from top to bottom Silo 21, first silo 22, second silo 23, horizontal synthesis kettle 24, first slag silo 25, second slag silo 26, third slag silo 27; bottom of storage silo 21, first silo 22 The bottom, the bottom of the first slag bin 25, the bottom of the second slag bin 26, and the bottom of the third slag bin 27 are respectively provided with a discharge valve 1, a discharge valve 2, a discharge valve 11, a discharge valve 12, and a discharge valve 13; The upper and lower parts of the first silo 22, the upper part of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com