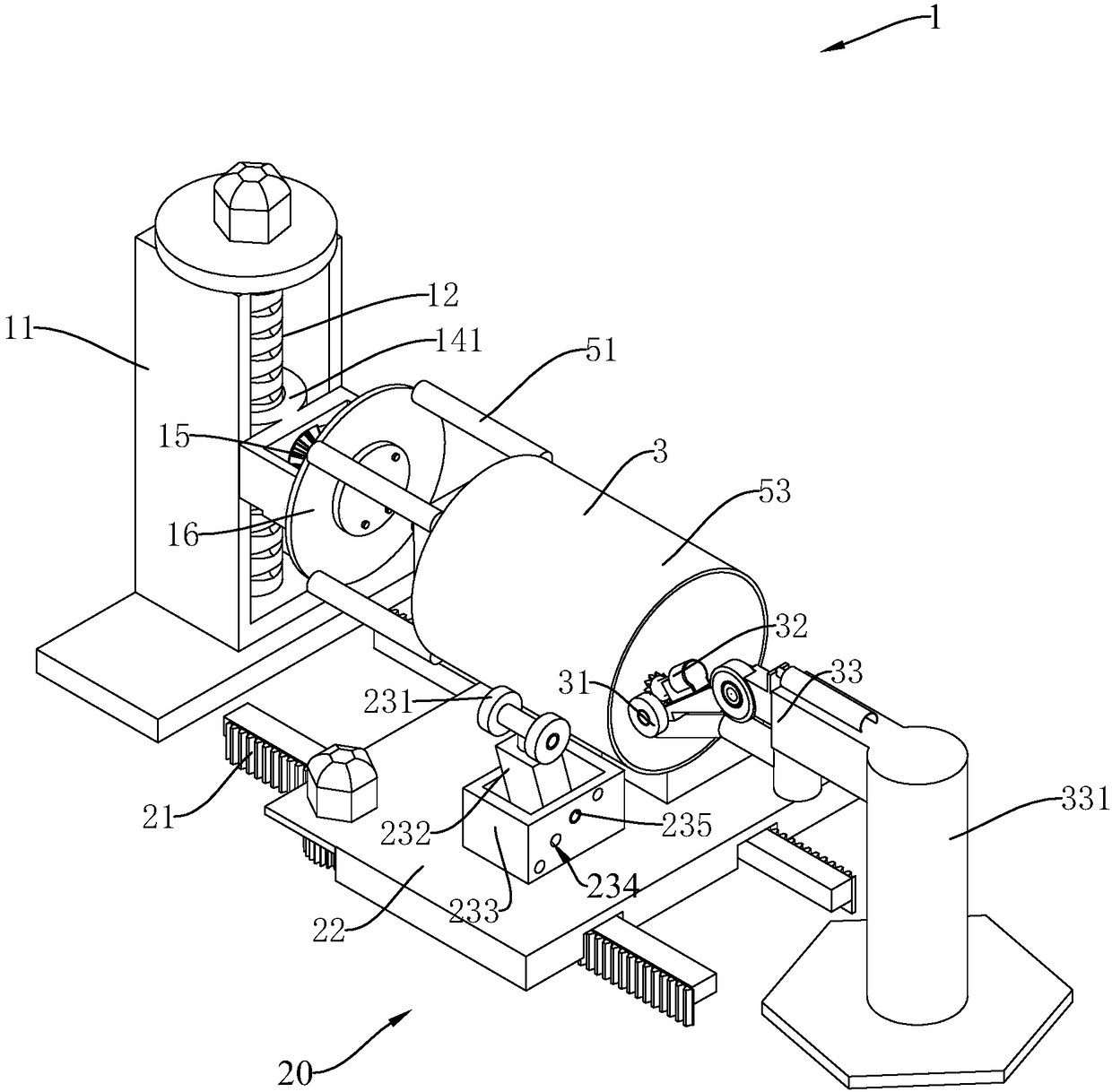

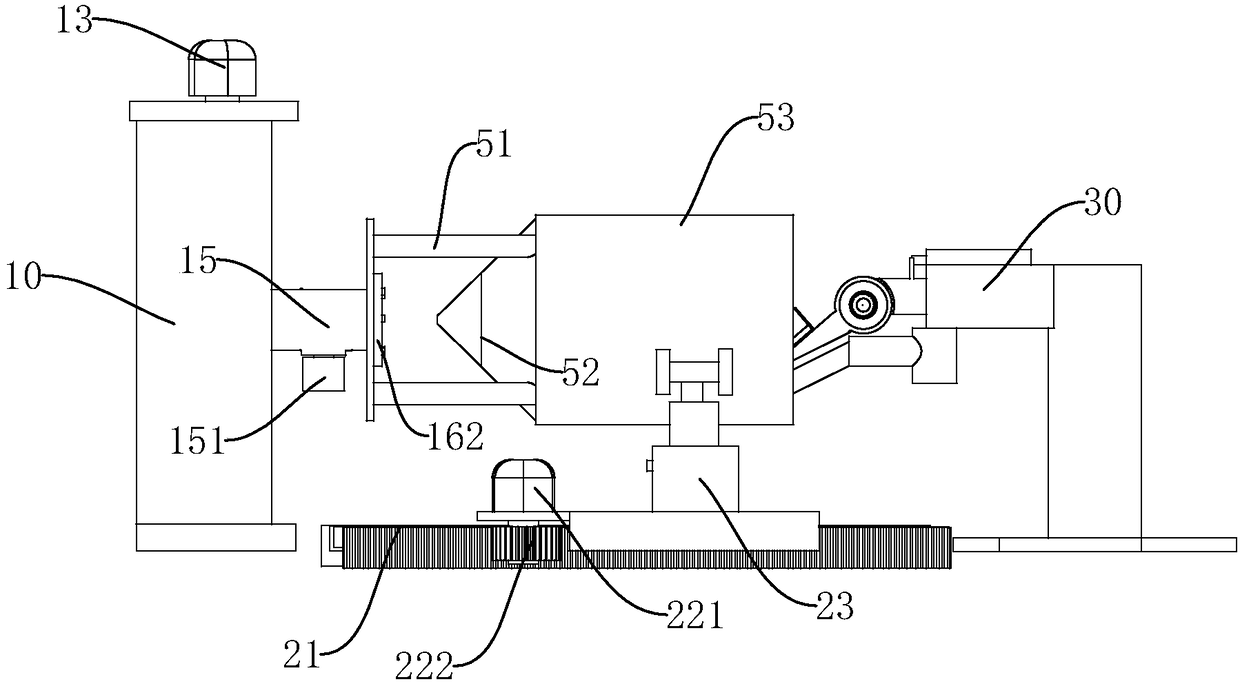

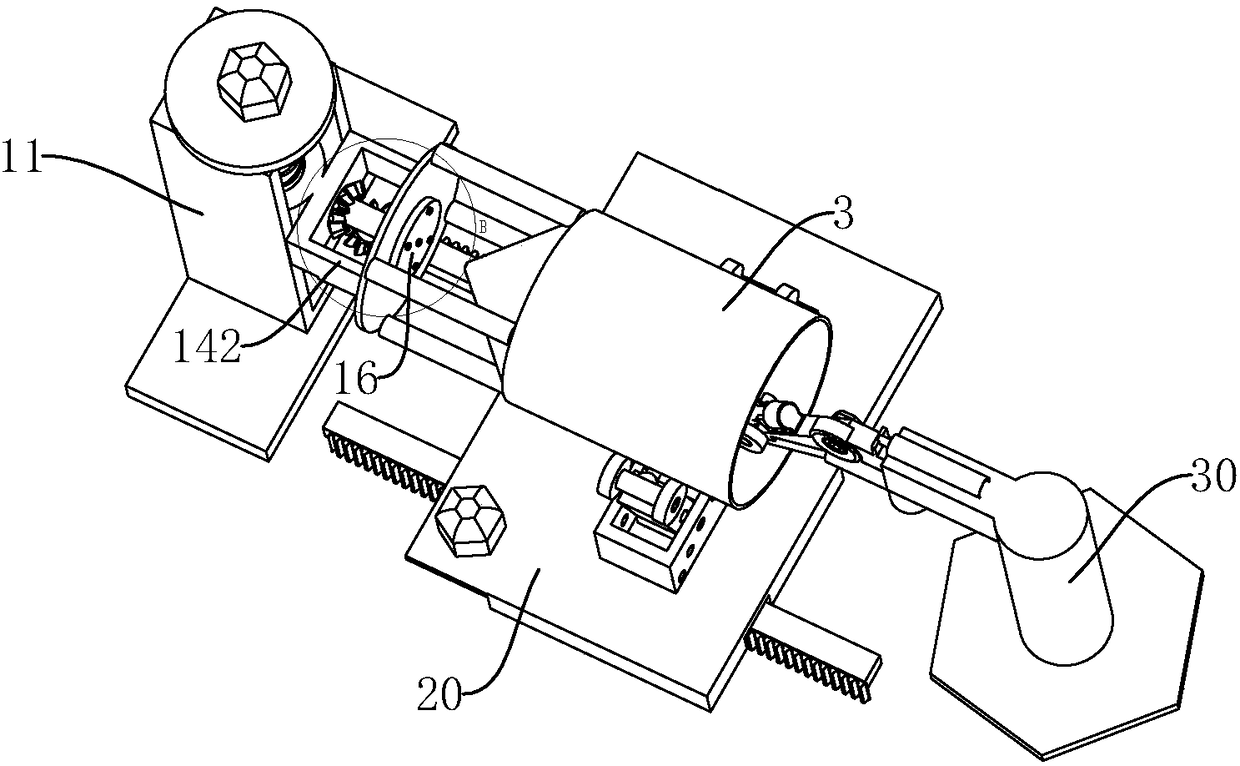

Surface polishing system and polishing method thereof

A technology of surface polishing and internal polishing, which is applied in the field of polishing, and can solve problems such as unsatisfactory polishing effect, large size, and inability to fully polish the tank body.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] (1) mechanical polishing, the inner and outer walls of the head 52 and the barrel 53 of the tank body 3 are respectively polished synchronously by the polishing device 1;

[0069] (2) degreasing and degreasing, cleaning the tank body 3 after mechanical polishing;

[0070] (3) Electrolytic polishing, add electrolytic polishing solution in the electrolytic cell, heat to 65°C with a titanium heating rod, stop heating after reaching the required temperature, hoist the tank body 3 into the electrolytic cell, and connect the tank body 3 as the anode, the insoluble metal as the cathode, and the second stage is set in the electrolytic cell at the same time, turn on the power rectifier switch, adjust the voltage to 12V, control the working current at 2500A, and the polishing time is 35 minutes;

[0071] (4) Soaking and washing, soaking the electropolished tank body 3 in the clear water tank for 15 minutes, washing it with clear water, and then drying or air-drying.

Embodiment 2

[0073] (1) mechanical polishing, the inner and outer walls of the head 52 and the barrel 53 of the tank body 3 are respectively polished synchronously by the polishing device 1;

[0074] (2) degreasing and degreasing, cleaning the tank body 3 after mechanical polishing;

[0075] (3) Electrolytic polishing, add electrolytic polishing solution in the electrolytic cell, heat to 30°C with a titanium heating rod, stop heating after reaching the required temperature, hoist the tank body 3 into the electrolytic cell, and connect the tank body 3 as the anode, the insoluble metal as the cathode, and the second stage is set in the electrolytic cell at the same time, turn on the power rectifier switch, adjust the voltage to 12V, control the working current at 2500A, and the polishing time is 35 minutes;

[0076] (4) Soaking and washing, soaking the electropolished tank body 3 in the clear water tank for 15 minutes, washing it with clear water, and then drying or air-drying.

Embodiment 3 to Embodiment 8

[0078] The polishing methods of Examples 3 to 8 are the same as in Example 1, except that the temperatures in the electrolytic polishing are different, which are 40°C, 50°C, 55°C, 60°C, 70°C, and 80°C respectively, and the roughness of the inner and outer surfaces The performance test is shown in Table 1.

[0079] The roughness property test of table 1 embodiment 1~8

[0080]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com