A method for improving the crystallization properties of aluminum chloride mother liquor in the "one-step acid solution" process

A technology of aluminum chloride and mother liquor, applied in the directions of aluminum chloride, aluminum halide, etc., can solve the problems of difficulty in solid-liquid separation, affecting the normal crystallization process of aluminum chloride, etc., and achieve the promoted increase and increase of aluminum chloride crystals. Effect of particle size and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

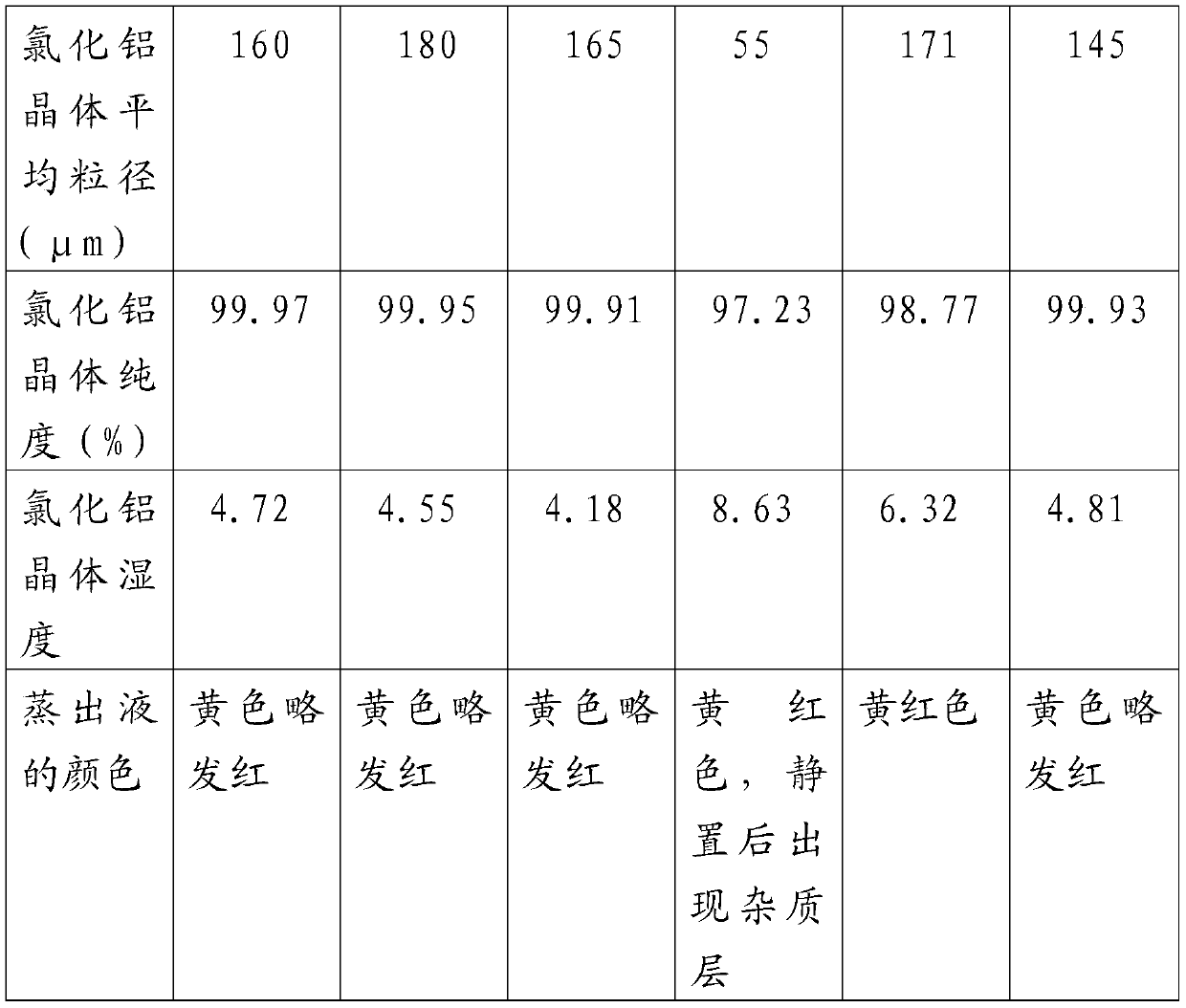

Embodiment 1

[0049] (1) adding pH value to the aluminum chloride mother liquor is 2, and the condensed water that temperature is 45 ℃ is diluted, is diluted to the mass concentration of aluminum chloride and is 360g / L, obtains aluminum chloride mother liquor dilution;

[0050] (2) After testing, the mass content of insoluble particles in the aluminum chloride mother liquor dilution is 8g / L; the aluminum chloride mother liquor dilution is evaporated and concentrated to obtain the distilled liquid, and the temperature of the evaporated concentration is 65°C;

[0051] (3) the temperature of the distilled liquid is reduced to 35° C. after the distilled liquid is left to stand for 2 hours. The volume content of the solid in the distilled liquid at this moment is 45%, and the viscosity of the distilled liquid is 170 cP. After the liquid is allowed to stand still, hydrochloric acid is added therein to adjust the acidity of the distilled liquid to 0.012mol / L;

[0052] (4) the above-mentioned solut...

Embodiment 2

[0054] (1) adding pH value to aluminum chloride mother liquor is 1, and temperature is 55 ℃ condensed water to dilute, the mass concentration of diluting to aluminum chloride is 370g / L, obtains aluminum chloride mother liquor dilution;

[0055] (2) After detecting that the mass content of insoluble particles in the aluminum chloride mother liquor dilution is 20g / L, after the aluminum chloride mother liquor dilution is centrifuged with a horizontal screw centrifuge, the insoluble particles and the aluminum chloride-containing solution, the rotating speed of the centrifuge is 4800r / min; the solution containing aluminum chloride is evaporated and concentrated to obtain the distilled liquid, and the temperature of the evaporated concentration is 67°C;

[0056] (3) The temperature of the distilled liquid is dropped to 38° C. after the distilled liquid is left to stand for 3 hours. After the liquid is allowed to stand, hydrochloric acid is added therein to adjust the acidity of the ...

Embodiment 3

[0059] (1) adding pH value to the aluminum chloride mother liquor is 2, and the condensed water that temperature is 50 ℃ is diluted, and the mass concentration of diluting to aluminum chloride is 380g / L, obtains aluminum chloride mother liquor dilution;

[0060] (2) After detecting that the mass content of insoluble particles in the aluminum chloride mother liquor dilution is 40g / L, after the aluminum chloride mother liquor dilution is centrifuged with a horizontal screw centrifuge, the insoluble particles and the aluminum chloride-containing solution, the rotating speed of the centrifuge is 4900r / min; the solution containing aluminum chloride is evaporated and concentrated to obtain the distilled liquid, and the temperature of the evaporated concentration is 69°C;

[0061] (3) The temperature of the distilled liquid was dropped to 38°C after the distilled liquid was left to stand for 2.5 hours. At this time, the volume content of the solid in the distilled liquid was 55%, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com