A kind of preparation method of hollow silver-loaded fiber

A silver-loaded fiber, hollow technology, applied in the field of textile fibers, can solve the problems of direct contact, low utilization rate of antibacterial effect, poor firmness, etc., and achieves the effect of uniform size, conducive to random selection, and easy to rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

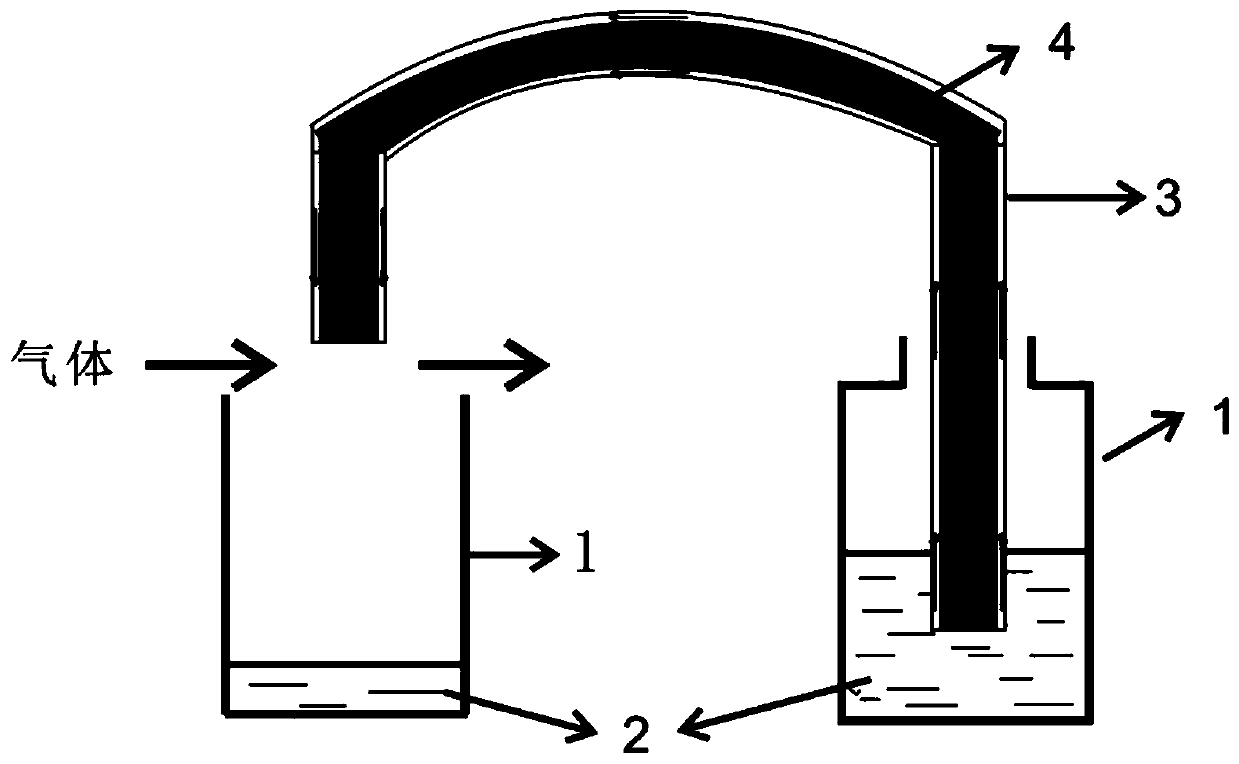

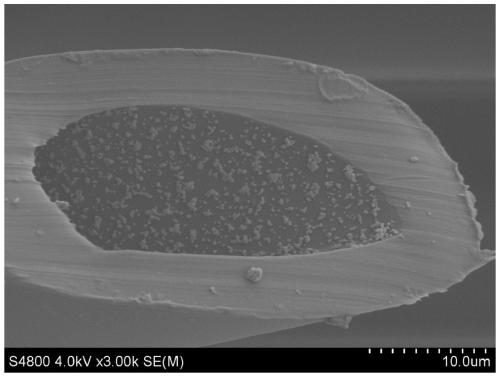

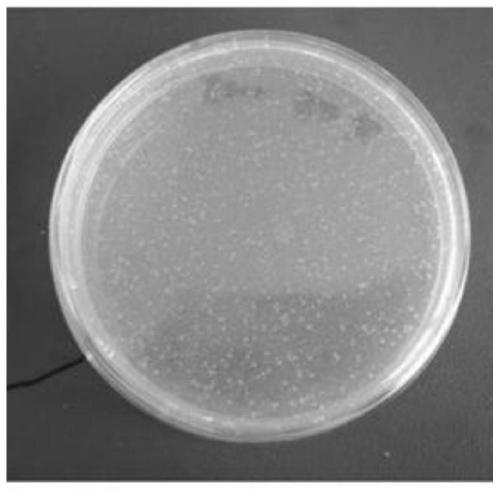

[0031] 1) Take a solid material and put it in the middle of the hollow fiber to obtain a hollow fiber with a solid material. The solid material does not react with the silver nitrate mixed solution, and the solid material can be a silver wire;

[0032] 2) Place the two ends of the hollow fiber pierced with solid matter in two disconnected containers respectively, submerge the first end of the hollow fiber in the silver nitrate mixed solution, and leave the second end of the hollow fiber empty in the In the container, a height difference is formed between the second end and the first end, and the height difference is 1 cm. The silver nitrate mixed solution includes ammonia water, AgNO with a volume ratio of 9:7:4. 3 solution and glucose solution, the concentration of ammonia water is 5% by mass, AgNO 3 The concentration of the solution is 10% by mass, and the concentration of glucose is 10% by mass;

[0033] 3) and vertically blow air at the end of the second end of the hollow...

Embodiment 2

[0040] 1) Take a solid substance and put it in the middle of the hollow fiber to obtain a hollow fiber with a solid substance, and the solid substance does not react with the silver nitrate mixed solution;

[0041] 2) Place the two ends of the hollow fiber in two disconnected containers respectively, submerge the first end of the hollow fiber in the silver nitrate mixed solution, leave the second end of the hollow fiber empty in the container, and make the second end A height difference H is formed between the first end and the first end, and the height difference is 5cm. The silver nitrate mixed solution includes ammonia water, AgNO 3 solution and glucose solution, the concentration of ammonia water is 2% by mass, AgNO3 The concentration of the solution is 4% by mass, and the concentration of glucose is 4% by mass;

[0042] 3) and blowing air vertically at the end of the second end of the hollow fiber with a flow rate of 10m / s, so that the silver nitrate mixed solution passes...

Embodiment 3

[0045] 1) Take a solid substance and put it in the middle of the hollow fiber to obtain a hollow fiber with a solid substance, and the solid substance does not react with the silver nitrate mixed solution;

[0046] 2) Place the two ends of the hollow fiber in two disconnected containers respectively, submerge the first end of the hollow fiber in the silver nitrate mixed solution, leave the second end of the hollow fiber empty in the container, and make the second end A height difference is formed between the first end and the first end, and the height difference is 10cm. The ammonia water and AgNO in the silver nitrate mixed solution 3 solution and glucose solution, the concentration of ammonia water is 10% by mass, AgNO 3 The concentration of the solution is 2% by mass, and the concentration of glucose is 0.2% by mass;

[0047] 3) and vertically blow air at the end of the second end of the hollow fiber with a flow rate of 100m / s, so that the silver nitrate mixed solution pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com