High-precision sheet material width detecting and cutting device

A width detection and cutting device technology, applied in the field of measurement, can solve the problems of inconvenient detection, easy to break the whole plate, high cost, etc., and achieve the effect of low labor intensity, good cutting effect and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

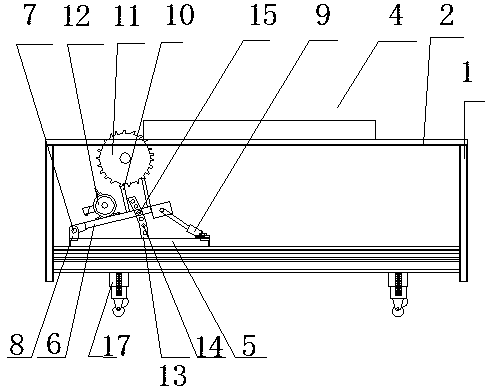

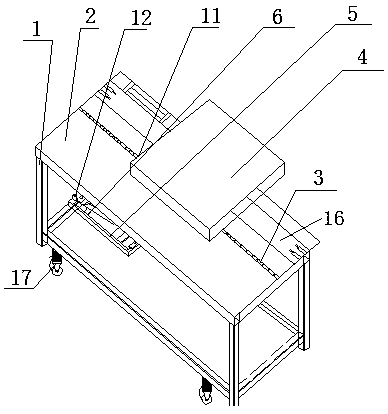

[0039] Specific embodiment 1: combine Figure 1-Figure 3 Shown: a high-precision plate width detection and cutting device, which includes a bracket 1, a cutting platform 2 is arranged on the bracket 1, a testing platform 16 is provided at the other end of the cutting platform 2, and a supporting device 17 is provided at the other end of the testing platform 16 ;

[0040] The cutting platform 2 is provided with a cutting groove 3, and the lower end of the cutting platform 2 is provided with a cutting mechanism. The cutting mechanism includes a fixed seat 5, on which a support swash plate 6 is installed, and the inclined lower end of the support swash plate 6 is hingedly installed by a pin shaft 7. The support seat 8 on the fixed seat 5, the inclined upper end of the support slant plate 6 is hinged to the piston rod of the overturn drive cylinder 9, the cylinder body of the overturn drive cylinder 9 is hingedly installed on the fixed seat 5, and the cutting seat 10 is installed ...

specific Embodiment 2

[0041] Specific embodiment 2: combine Figure 4 is a system block diagram of the plate non-destructive testing method in the embodiment of the present invention, such as Figure 4 shown, including the following aspects:

[0042] 1. The device 101 for detecting the thickness of the plate is used to measure the thickness of the plate. The measurement of thickness is mainly to measure the small variation of thickness. The thickness of each batch of wood in the factory is roughly the same, which can be expressed as (W+Δw). First, set this standard quantity as W, and only need to measure the variation Δw (Δw has positive and negative points) between each piece of wood and the standard value. By giving a fixed distance between a pair of displacement sensors, when the thickness changes, the displacement sensor the amount of indentation changes, the signal conditioning circuit through the

[0043] Road, the signal is collected into the controller, so as to calculate the thickness. ...

specific Embodiment 3

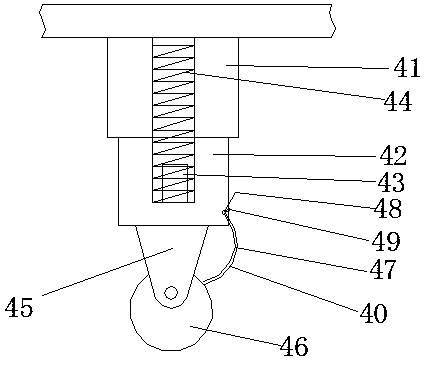

[0064] Specific embodiment 3, in combination image 3 A roller device 17 is provided below the cutting platform, and the roller device 17 includes a first telescopic rod 41, a second telescopic rod 42 slidably connected with the first telescopic rod 41, and a limiter set in the second telescopic rod 42. The position pin 43, the compression spring 44 sleeved on the limit pin 43, the roller support 45 connected to the bottom of the second telescopic rod 42, the roller 46 connected to the roller support 45 through the rotating shaft, and the rollers 46 evenly distributed on the outside of the roller 46 Groove, the limiting device 47 arranged on the outside of the second telescopic rod 42 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com