Ceramic pressure measurement cell having at least one temperature transducer and pressure sensor having a pressure measurement cell of this type

A measurement unit, pressure technology, applied in the direction of measuring heat, thermometers, measuring devices, etc., can solve problems such as unfavorable and affect the mechanical stress associated with pressure measurement, and achieve the effect of promoting correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

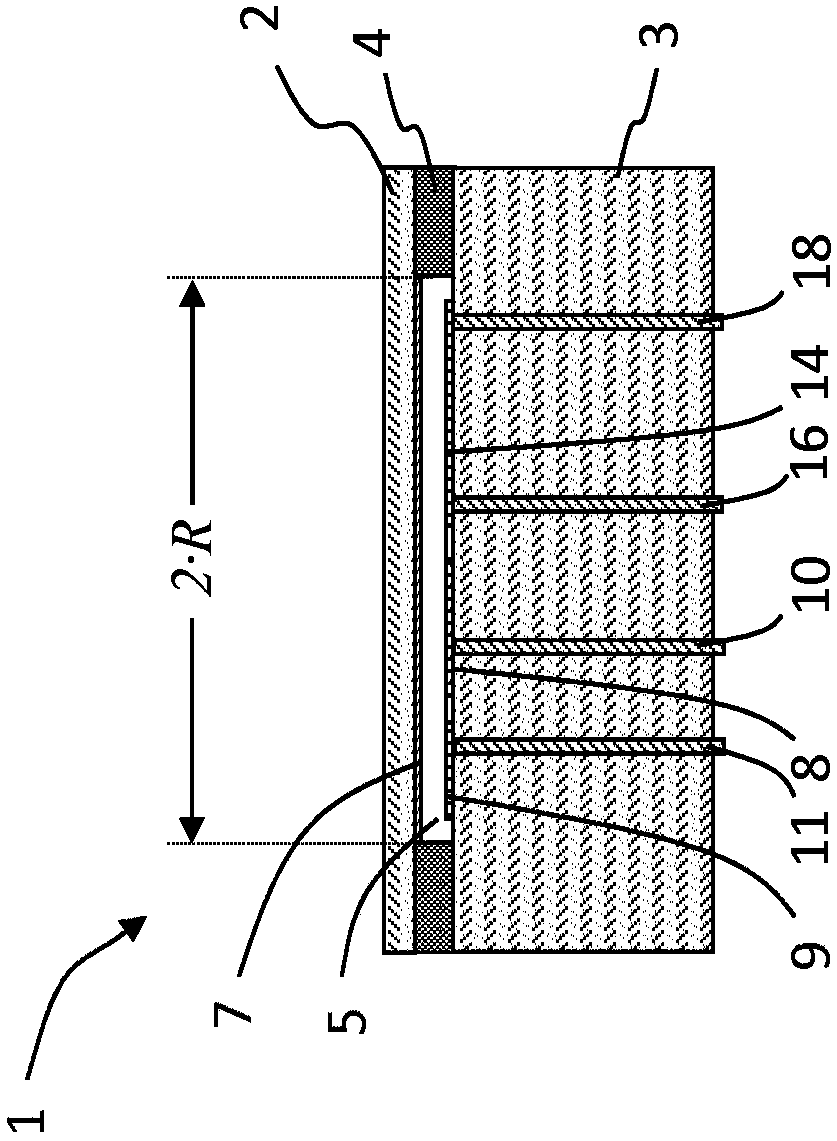

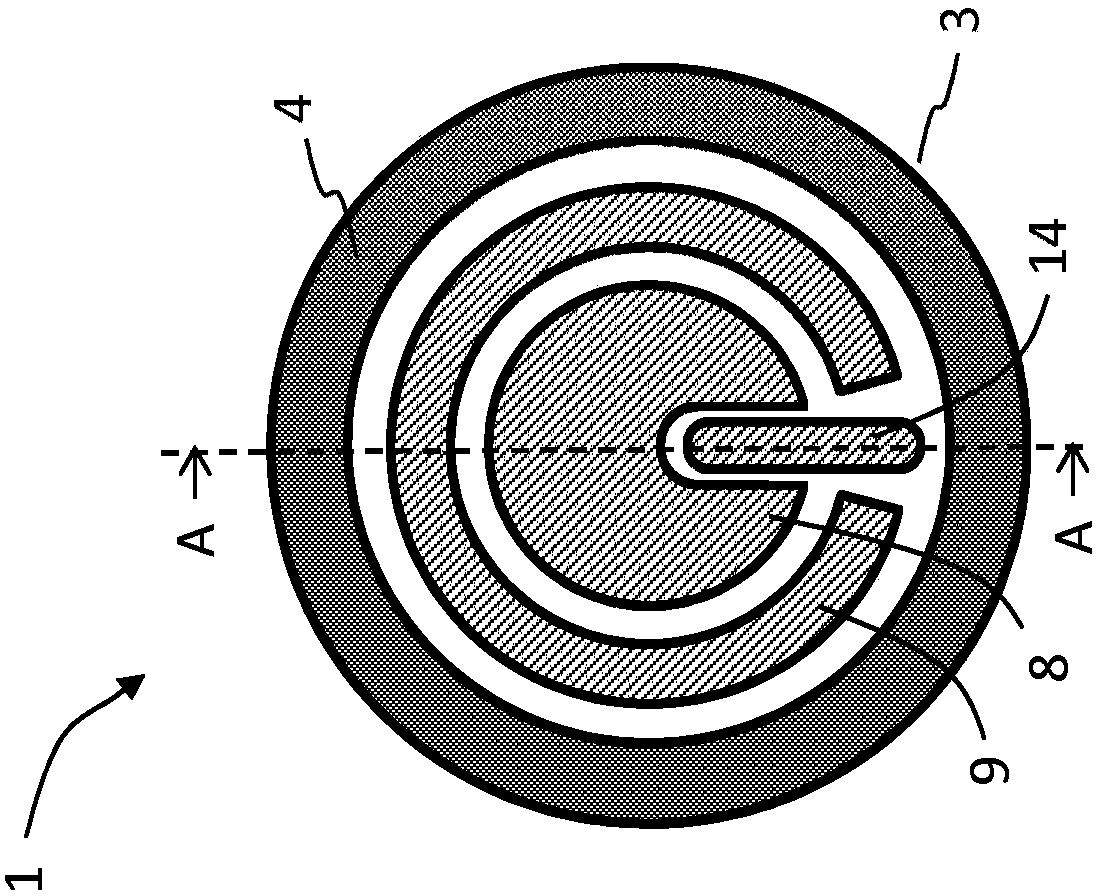

[0039] Figure 1a and Figure 1b The exemplary embodiment of a pressure measuring cell 1 according to the invention represented in comprises a disc-shaped ceramic measuring diaphragm 2 joined in a pressure-tight manner along an outer circumferential joint 4 to a substantially harder disc-shaped ceramic The opposite body 3 forms a measurement chamber 5 between the opposite body 3 and the measurement diaphragm 2 . The measuring diaphragm 2 and the counter-body consist in particular of corundum. The joint may in particular comprise an active braze, for example a Zr—Ni—Ti active braze.

[0040] The measuring diaphragm 2 has on its opposite body side surface a full-surface diaphragm electrode 7 with a radius R, where R is the radius of the flexible region of the measuring diaphragm, which corresponds to the junction 4 inner diameter. On the diaphragm-side end of the counter body 3 a central measuring electrode 8 is arranged cross-sectionally surrounded by a reference electrode 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com