Catalytic oxidizing device and method for efficiently treating VOCs organic waste gas

An organic waste gas, catalytic oxidation technology, applied in chemical instruments and methods, gas treatment, separation methods, etc., can solve the problems of inconvenient regeneration and replacement, complex reactor structure, uneven air distribution, etc., to achieve uniform load and ensure catalyst utilization. rate, the effect of optimizing the airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The principles and features of the present invention will be described below in conjunction with the drawings and embodiments, and the embodiments are only used to explain the present invention, not to limit the scope of the present invention.

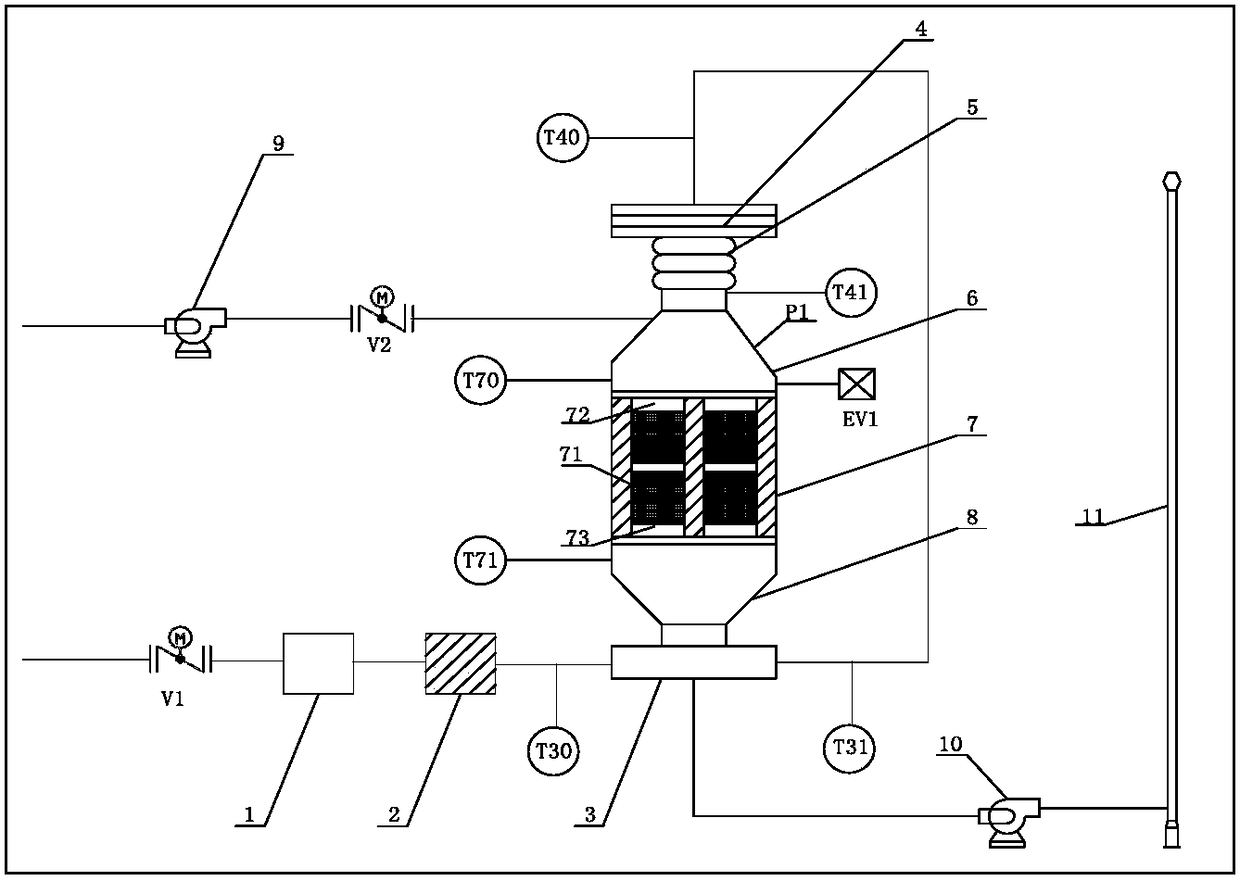

[0036] figure 1 It is a structural schematic diagram of a catalytic oxidation device for efficiently treating VOCs organic waste gas according to the present invention, including a dry filter 1, a flame arrester 2, a heat exchanger 3, a heater 4 and a catalytic-oxidation reactor, wherein the dry filter One end of 1 is connected to the exhaust gas discharge end or the adsorption concentration desorption end through the intake electric valve V1, and the other end of the dry filter 1 is connected to the flame arrester 2; the flame arrester 2 is connected to the heat exchange The inlet of the cold end of the heat exchanger 3 is connected, the outlet of the cold end of the heat exchanger 3 is connected with the inlet of the heater 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com