Emulsified asphalt anti-collapse agent and preparation method thereof

A technology of emulsified asphalt and anti-collapse agent, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of unusable and loss of the function of sealing the well wall, etc., to improve the temperature resistance and softening point , the effect of strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The embodiment of the present invention also provides a kind of preparation method of above-mentioned emulsified asphalt antislumping agent, comprises the following steps:

[0032] First react the epoxy resin with the curing agent to obtain a reaction product with a three-dimensional network structure;

[0033] The reaction product is then added to the emulsified bitumen.

[0034] For specific applications, put the epoxy resin in a container, slowly add the curing agent to the epoxy resin, and stir while adding to ensure that the epoxy resin and the curing agent fully react. The reaction time is about 30 minutes, and a three-dimensional The reaction product of the network structure, after the reaction is completed, slowly add the reaction product to the emulsified asphalt and stir while adding to ensure that the emulsified asphalt dissolves into the three-dimensional network viscous liquid formed by the reaction of epoxy resin and curing agent to form emulsified asphalt...

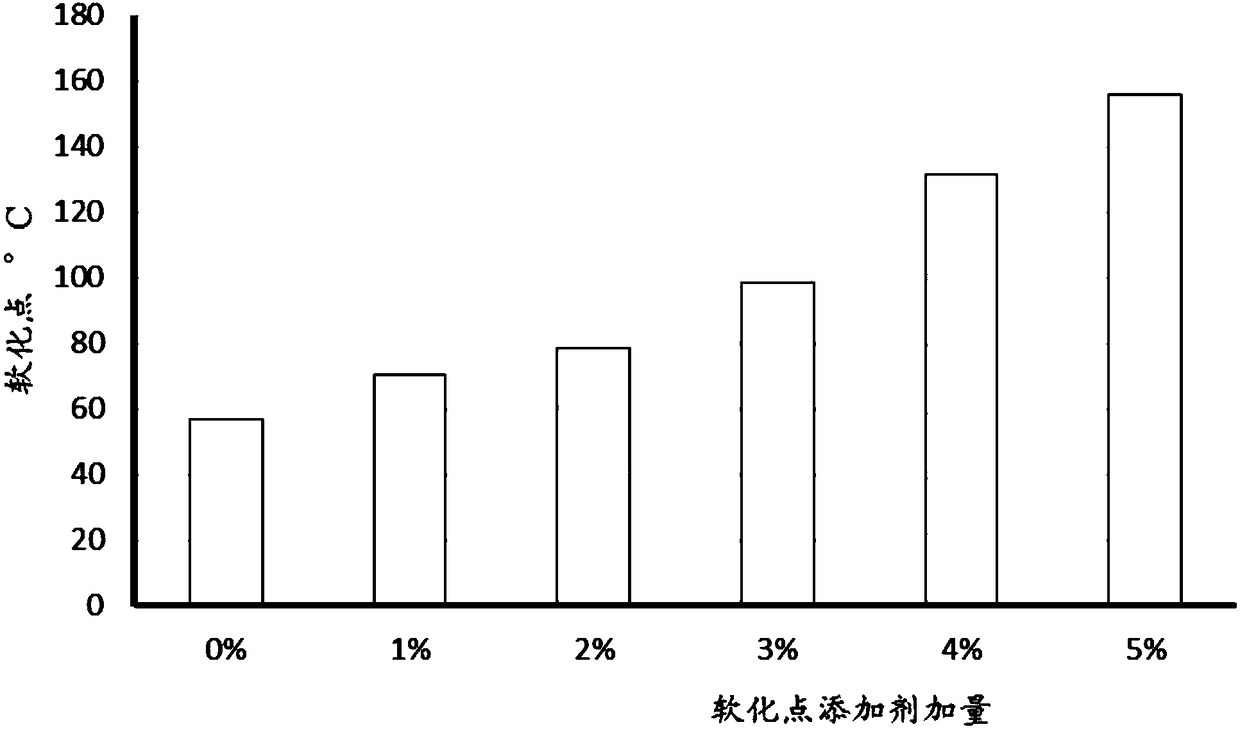

Embodiment 1

[0043]Using bisphenol A epichlorohydrin resin as epoxy resin, ethylenediamine as curing agent, according to the mass ratio of bisphenol A epichlorohydrin resin and ethylenediamine is 1:0.85, slowly add ethylenediamine into bisphenol A In the phenol A epichlorohydrin resin, stir while adding to ensure that the bisphenol A epichlorohydrin resin and ethylenediamine fully react. The reaction time is controlled at 30min. After the reaction is completed, the reaction product is slowly added to the emulsified asphalt. The amount is 5.0% of the mass of emulsified asphalt. Stir while adding to ensure that the emulsified asphalt is dissolved into the three-dimensional network viscous liquid formed by the reaction of bisphenol A epichlorohydrin resin and ethylenediamine. The stirring time is controlled at 40min to obtain emulsified asphalt Anti-slump agent. After sampling and demulsification, use an automatic asphalt softening point tester to test its softening point, and the softening p...

Embodiment 2

[0045] Novolac epoxy resin is used as epoxy resin, and ethylenediamine is used as curing agent. According to the mass ratio of novolac epoxy resin and ethylenediamine as 1:0.8, ethylenediamine is slowly added into novolac epoxy resin, while adding Stir to ensure that novolac epoxy resin and ethylenediamine fully react. The reaction time is controlled at 30 minutes. After the reaction is completed, slowly add the reaction product to the emulsified asphalt. The amount added is 4.5% of the mass of the emulsified asphalt. The asphalt is melted into the three-dimensional network viscous liquid formed by the reaction of novolac epoxy resin and ethylenediamine, and the stirring time is controlled at 40 minutes; an emulsified asphalt anti-slump agent is obtained. After sampling and demulsification, the softening point was tested with an automatic asphalt softening point tester, and the softening point was 137°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com