Polyester fibre/modified polyester fiber blended fabric dyeing method

A technology of blended fabrics and dyeing methods, applied in dyeing methods, textiles and papermaking, etc., can solve problems such as affecting aesthetics and comfort, poor hygroscopicity, and dust contamination, so as to improve the coloring effect, reduce the use of dyes, and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The traditional dyeing process and the method of the present invention are respectively used to dye polyester / modified polyester / spandex (80 / 15 / 5) blended fabrics.

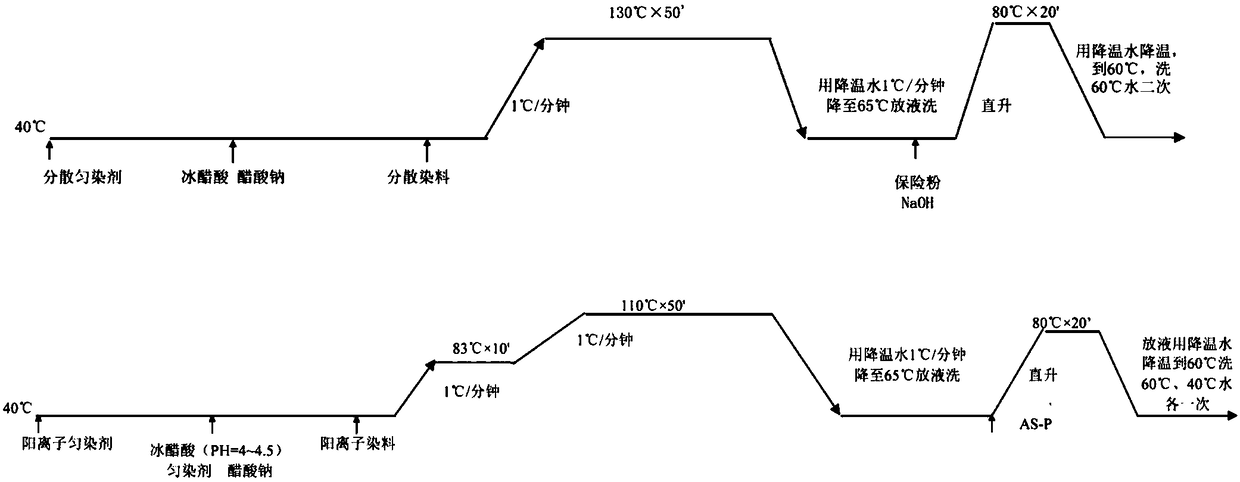

[0032] (1) The traditional dyeing process is: pre-setting → pre-treatment → dyeing polyester → cleaning → dyeing modified polyester → cleaning → washing water → dehydration and drying; the process time flow is as follows: figure 1 as shown,

[0033] The dyeing materials are:

[0034] Dyed polyester:

[0035] Disperse dye black SW-R 3%; Glacial acetic acid / (g / L)1; Sodium acetate / (g / L)1; Disperse leveling agent / (g / L)0.5;

[0036] Polyester cleaning:

[0037] Acid cleaning agent / (g / L)2; glacial acetic acid / (g / L)1

[0038] Dyed modified polyester:

[0039] Cationic dye black CA 1%; Glacial acetic acid / (g / L)1; Sodium acetate / (g / L)1; Cationic leveling agent / (g / L)0.5;

[0040] Modified polyester cleaning:

[0041] Cleaning agent / (g / L) 1.5.

[0042] (2) Dyeing process of the present invention: presetting → ...

Embodiment 2

[0059] Use the method of the present invention to dye 80% polyester 20% modified polyester blended+20DPU single jersey.

[0060] The color code is QFL-2 black, and the weight of the fabric is 160g / ㎡;

[0062] Disperse Cationic Red CD 0.02%, Disperse Cationic Yellow CD 0.3%, Disperse Cationic CD 0.19%, Disperse Red 4B 0.1%, Disperse Yellow GG 0.2%, Disperse Black S-R 3.3%, Dyeing Pigment 2g / L, Anti-sedimentation Agent 1g / L, acid cleaning agent 2g / L, glacial acetic acid 1g / L.

[0063] The specific dyeing process is:

[0064] (1) Pre-type

[0065] Raise the temperature of the stenter setting machine to 195 ° C ± 2, and control the cloth speed at 20 m / min for pre-setting;

[0066] (2) Dyeing

[0067] Put the knitted fabric into the dyeing vat, add cold water at 40°C±2 to the dyeing vat and control the bath ratio to 1:4-5; add anti-sedimentation agent and dyeing pigment to the dyeing vat in turn, with an interval of 5 minutes; disperse cations Add the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com