Epitaxial filling method of deep trench

A filling method and deep trench technology, which are applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to achieve the effect of improving aspect ratio, improving device performance, and eliminating filling defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

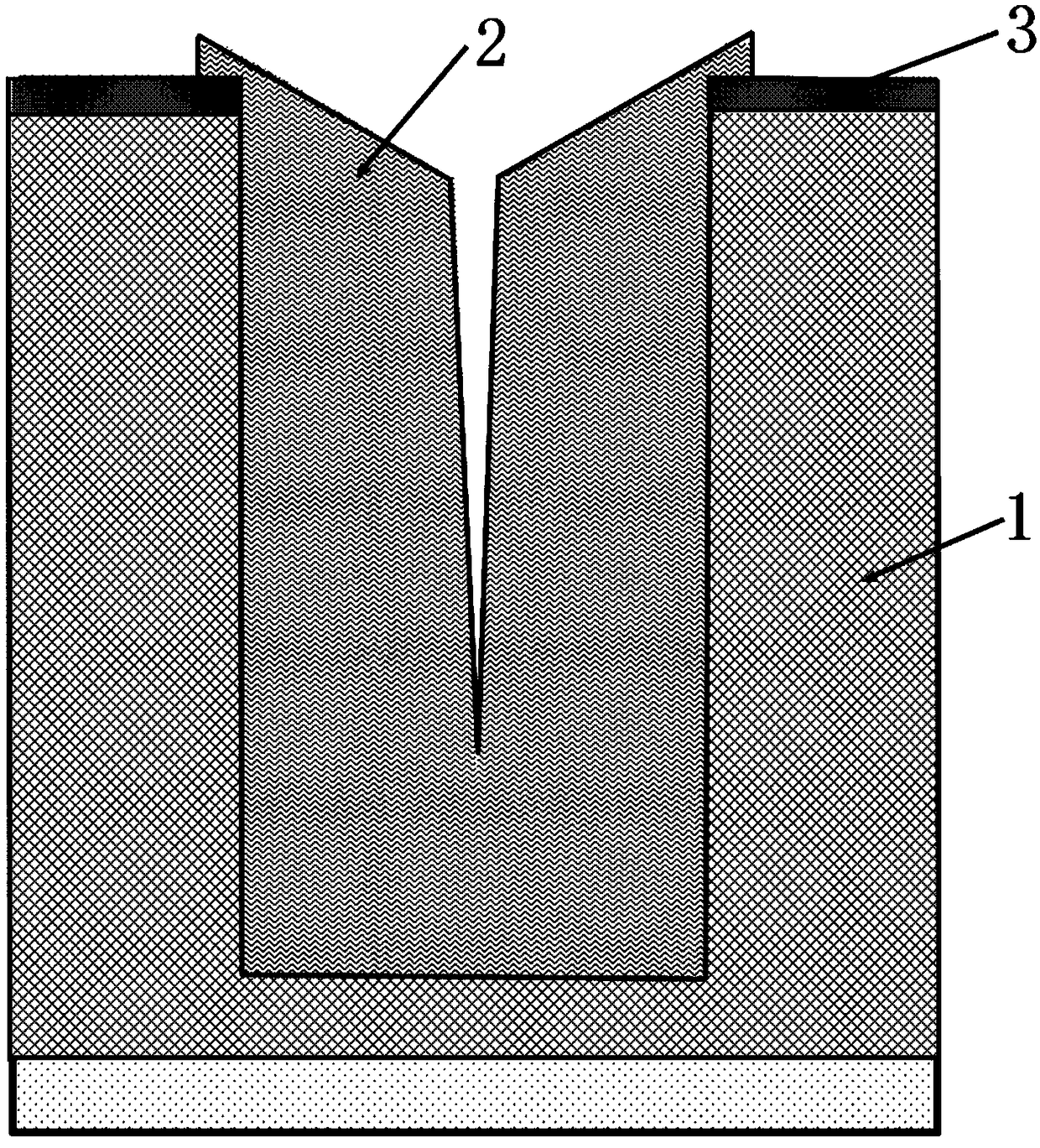

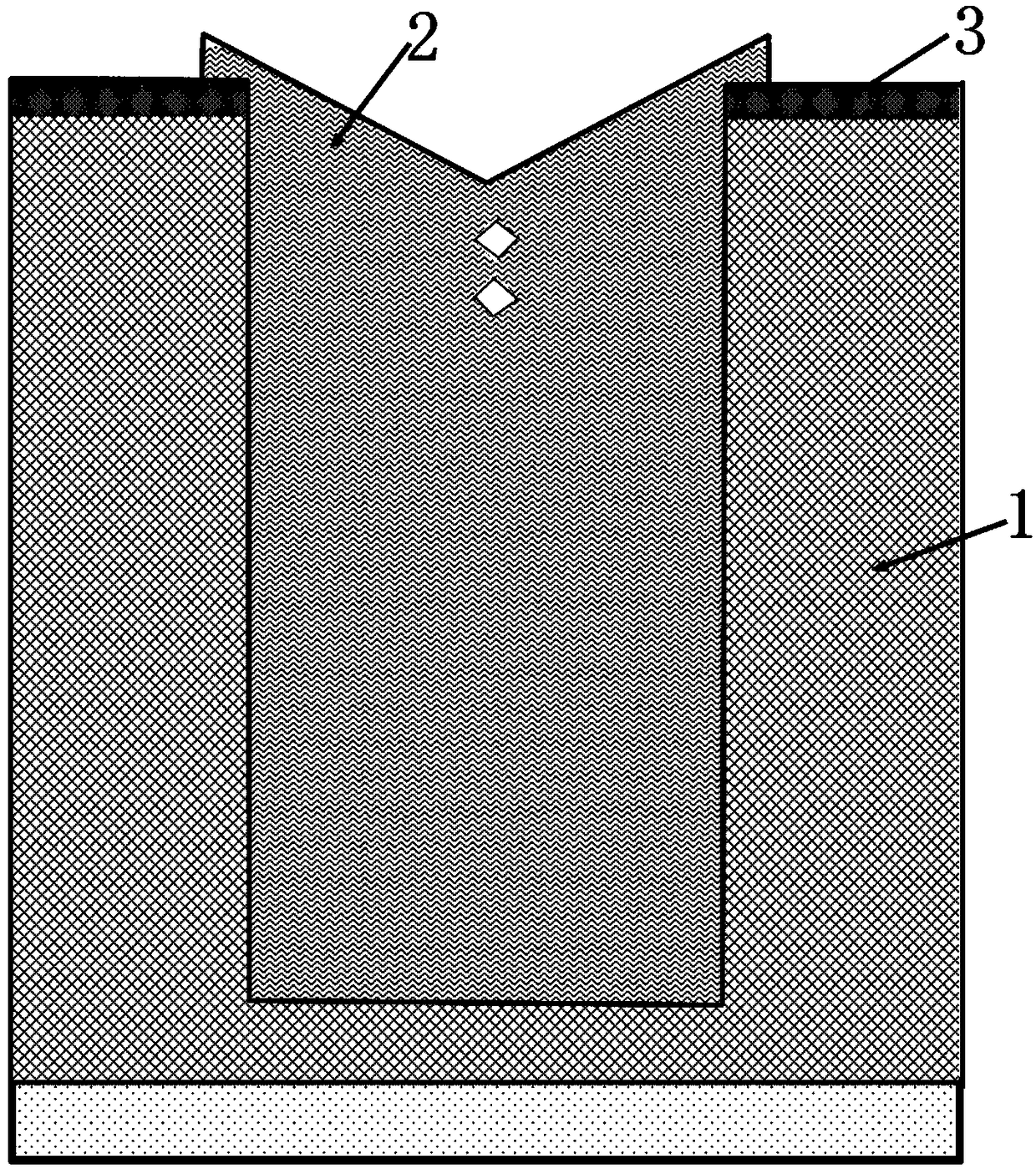

[0021] In the deep trench epitaxial filling method of the present invention, when the deep trench is epitaxially filled, the first epitaxial filling is performed first, and the filling is carried out to the edge of the deep trench without filling the trench. During an epitaxial filling, due to the morphology of the deep groove edge, the surface of the deep groove will form a slit, cavity or uneven surface near the edge of the deep groove; then use the hard mask layer on the wafer surface As a polishing stop layer, chemical mechanical polishing is performed to smooth the surface of the wafer, and then the epitaxial in the trench is etched, and the hard mask layer is used as an etching stop layer to etch all the defective parts of the epitaxial in the trench After the etching is completed, the inner and outer surfaces of the trench are smooth; finally, the second epitaxial filling is performed until the inner and outer surfaces of the trench are filled.

[0022] The present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com