Contact pressure detecting system aiming at belt sander

A contact pressure and detection system technology, which is applied in the direction of abrasive belt grinders, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of lack of research on contact pressure detection systems, no contact pressure detection systems, etc., to achieve shape and Small size, simple structure, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be described further below in conjunction with the accompanying drawings.

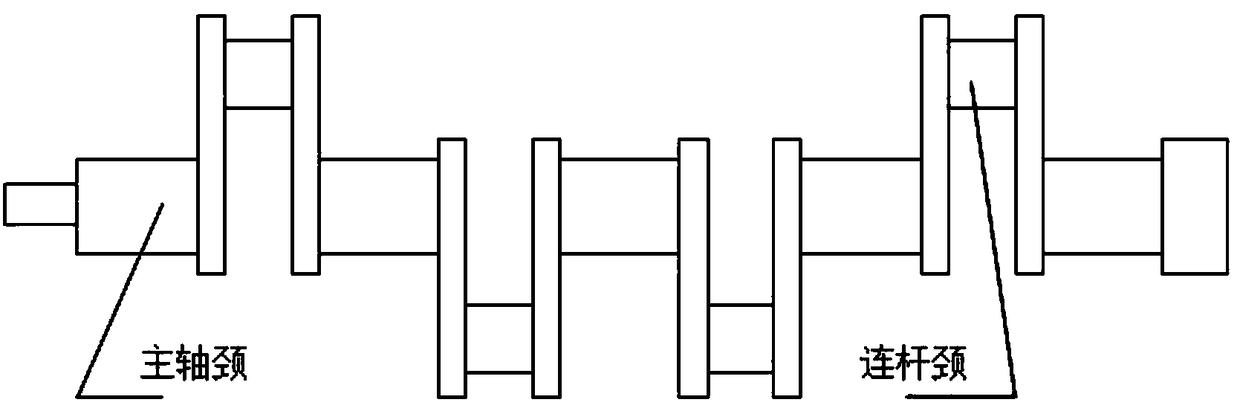

[0022] see figure 1 , the embodiment of the present invention is provided with machining workpiece crankshaft.

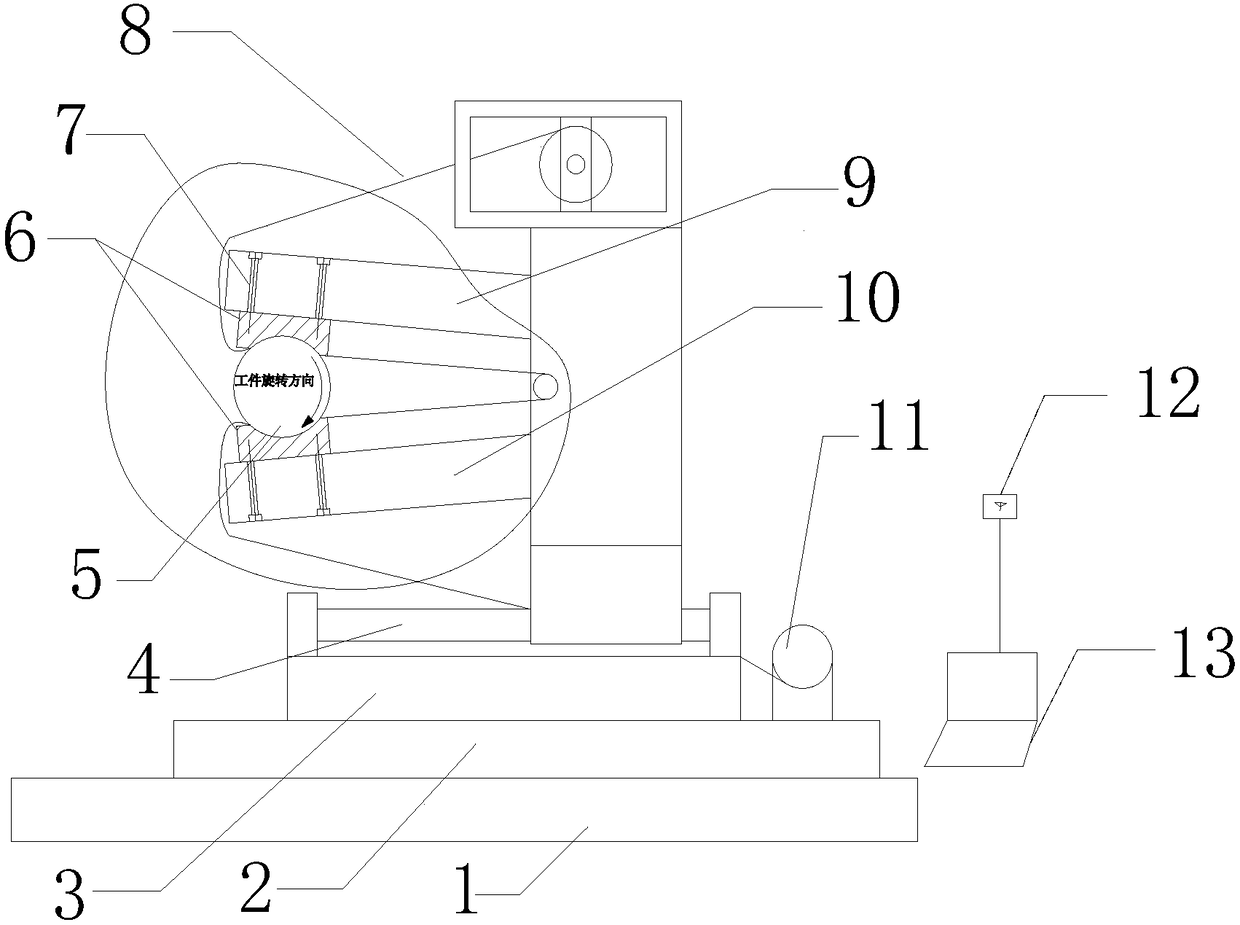

[0023] see figure 2 , the embodiment of the present invention is provided with workpiece 5, two customized polyurethane polishing blocks 6, abrasive belt 8, upper polishing arm 9, lower polishing arm 10, wireless receiving device 12, PC 13, workpiece 5 and abrasive belt 8 are used for For the generation of contact pressure in the implementation of the present invention, two polyurethane polishing blocks are used to detect the contact pressure generated between the workpiece and the abrasive belt during the working process of the abrasive belt polisher and perform signal transmission, and the wireless receiving device is connected to the PC.

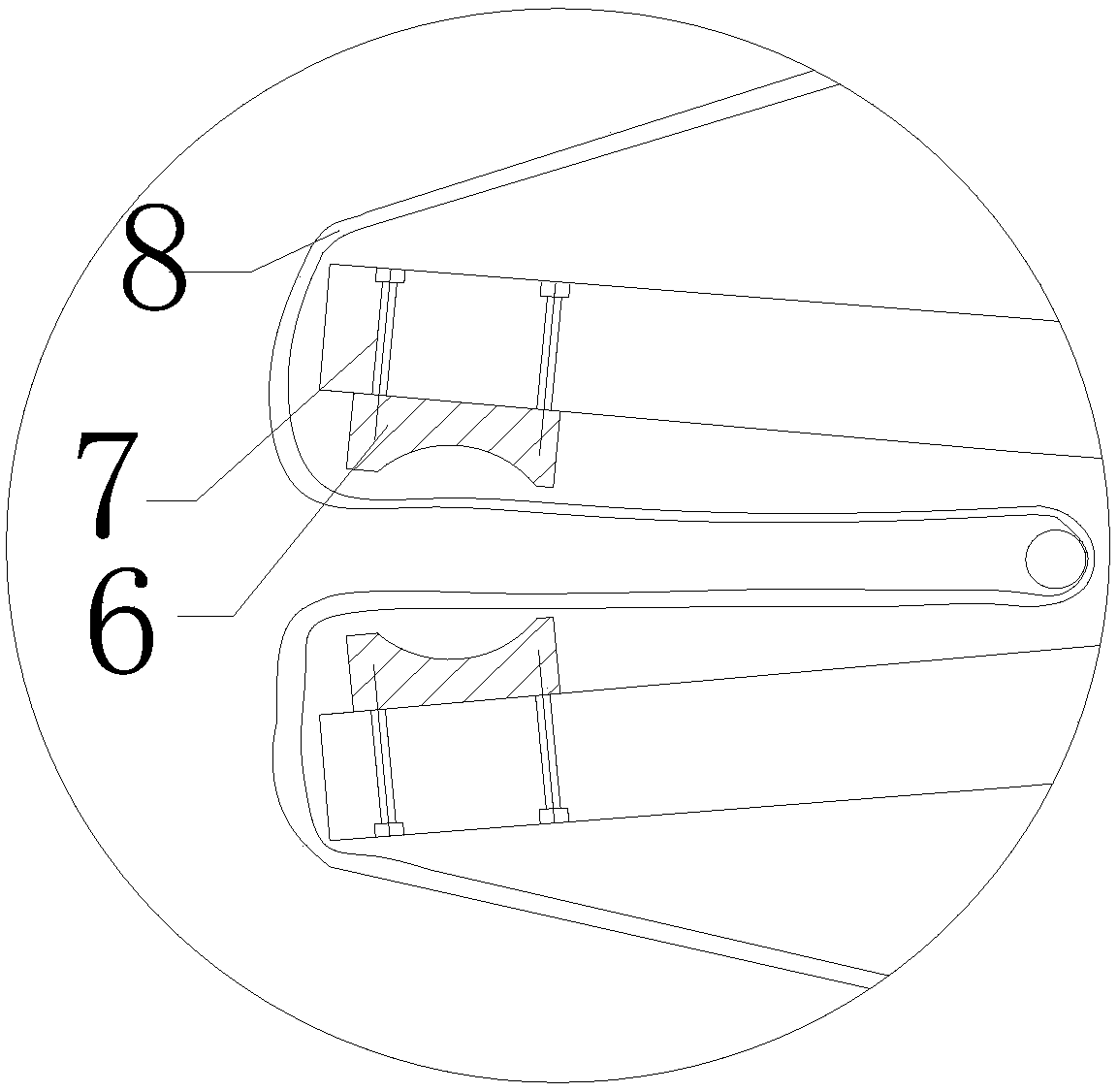

[0024] see image 3 , is the local schematic diagram of the position of the polishing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com