Blade-root connector of ocean current energy driven generator set and connecting method thereof

A generator set and blade root technology, which is applied to the blade root connector of an ocean current energy generator set and its connection field, can solve the problems of increasing the manufacturing cost and cycle, consuming a lot of time and manpower, and complex manufacturing and processing technology, and reducing the Stress concentration effect, cost saving, effect of large platen thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

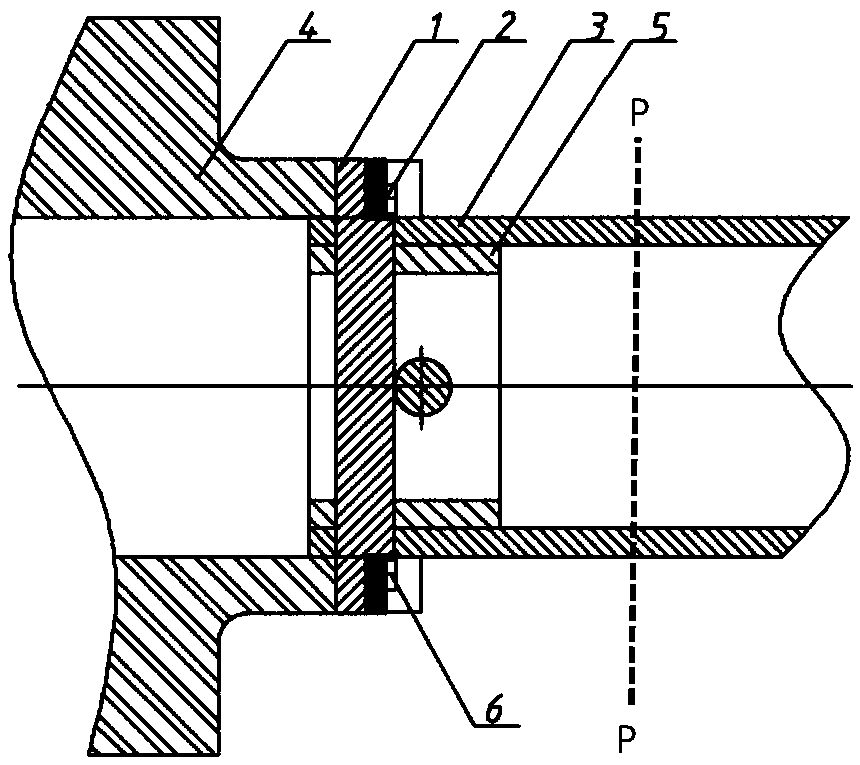

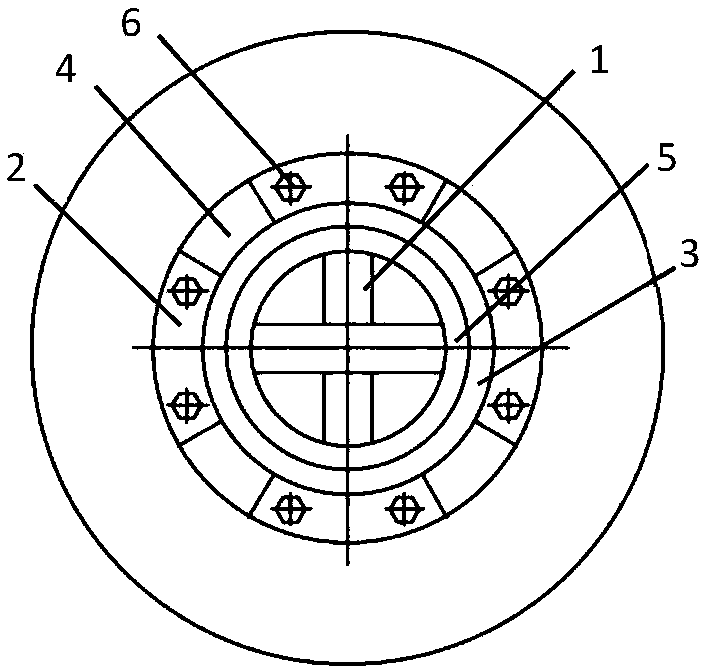

[0033] Such as figure 1 As shown in -3, the sea current energy generating set blade root connector of the present invention includes a wing bar 1, a pressure plate 2, a toothed hub 4, a reinforcement 5 and a pressure plate screw 6, and the reinforcement 5 is installed in the root of the blade 3, The outer diameter of the reinforcing member 5 is the same as the inner diameter of the blade 3, M through holes are evenly arranged in the circumferential direction of the root of the blade 3, and four through holes are arranged in this embodiment, and N mounting holes are evenly arranged in the circumferential direction of the reinforcing member 5, In this embodiment, four installation holes are set, and four semi-cylindrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com