A pressure-controlled low-temperature storage tank with an injection device

A low-temperature storage tank and injection device technology, which is applied to fixed-capacity gas storage tanks, pressure vessels, and container discharge methods, etc., can solve the problems of cold energy loss, simple structure, and reasonable and effective use of low-temperature exhaust gas without consideration, and achieves The effect of good control, simple structure, good application value and promotion prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

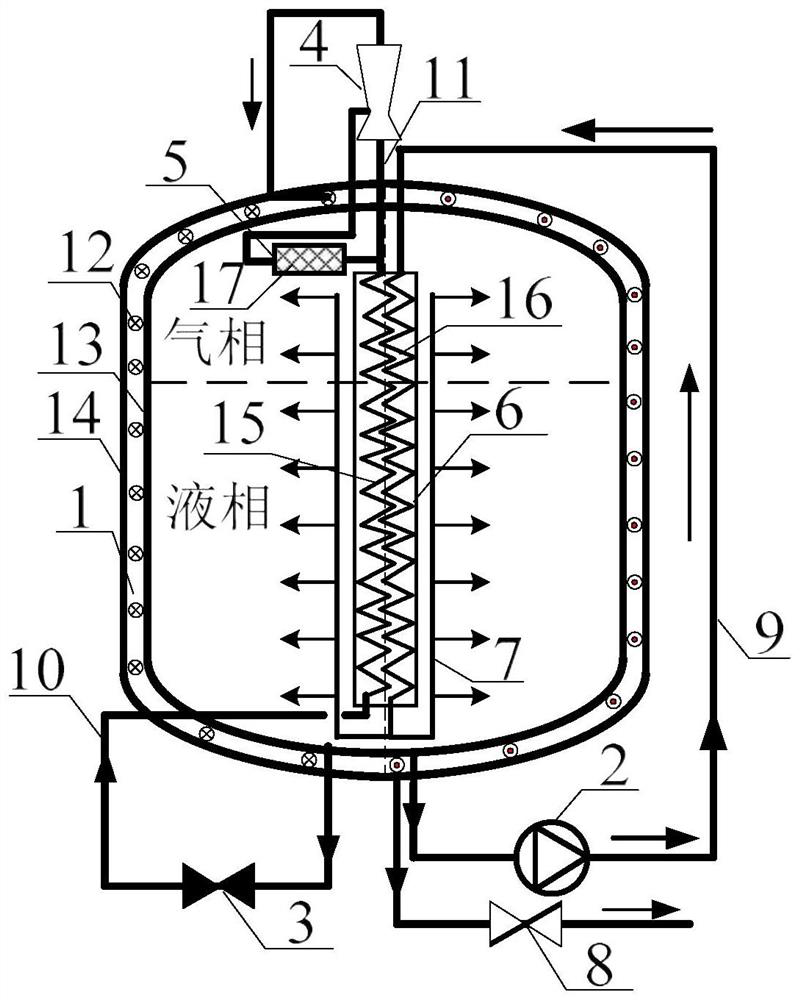

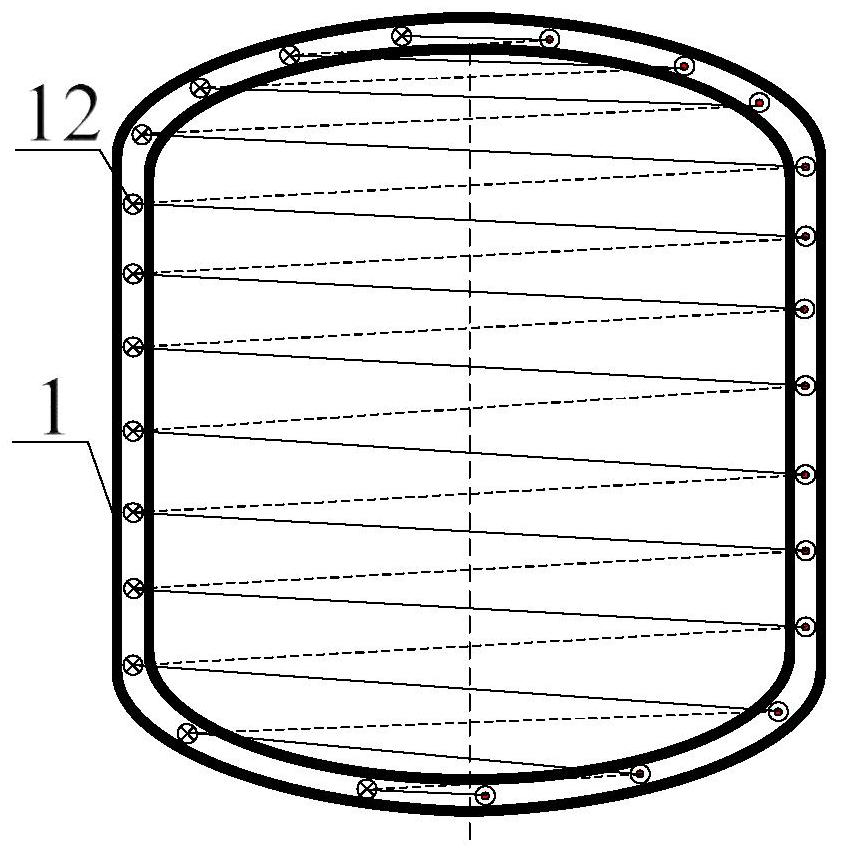

[0032] like figure 1 and figure 2 As shown, a pressure-controlled low-temperature storage tank with an injection device includes a tank body 1, a low-temperature circulation pump 2, a liquid throttle valve 3, an ejector 4, an ortho-parahydrogen conversion device 5, a heat exchanger 6, and a fluid Ejector 7, exhaust valve 8, bulk fluid circulation pipeline 9, throttling refrigeration pipeline 10, exhaust pipeline 11, and exhaust cooling coil 12.

[0033] The tank body 1 includes an inner tank 13 and an outer tank 14 . A heat insulating material is filled between the inner tank 13 and the outer tank 14 to form a heat insulating layer. The exhaust cooling coil 12 is arranged coiled around the inner tank 13 in the void of the insulation material. An ortho-parahydrogen conversion device 5 , a heat exchanger 6 and a fluid injector 7 are arranged in the inner space of the tank body 1 . The cryogenic circulation pump 2 , the liquid throttle valve 3 , the injector 4 and the exhaus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com