Efficient pressure-control cryogenic propellant storage tank with ejector

A low-temperature propellant and storage tank technology, which is applied in tank trucks, packaging, transportation and packaging, etc., can solve the problems of cold energy loss, reasonable and effective utilization of low-temperature exhaust gas, etc., to reduce thermal stress intensity, realize rational utilization, The effect of improving stability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

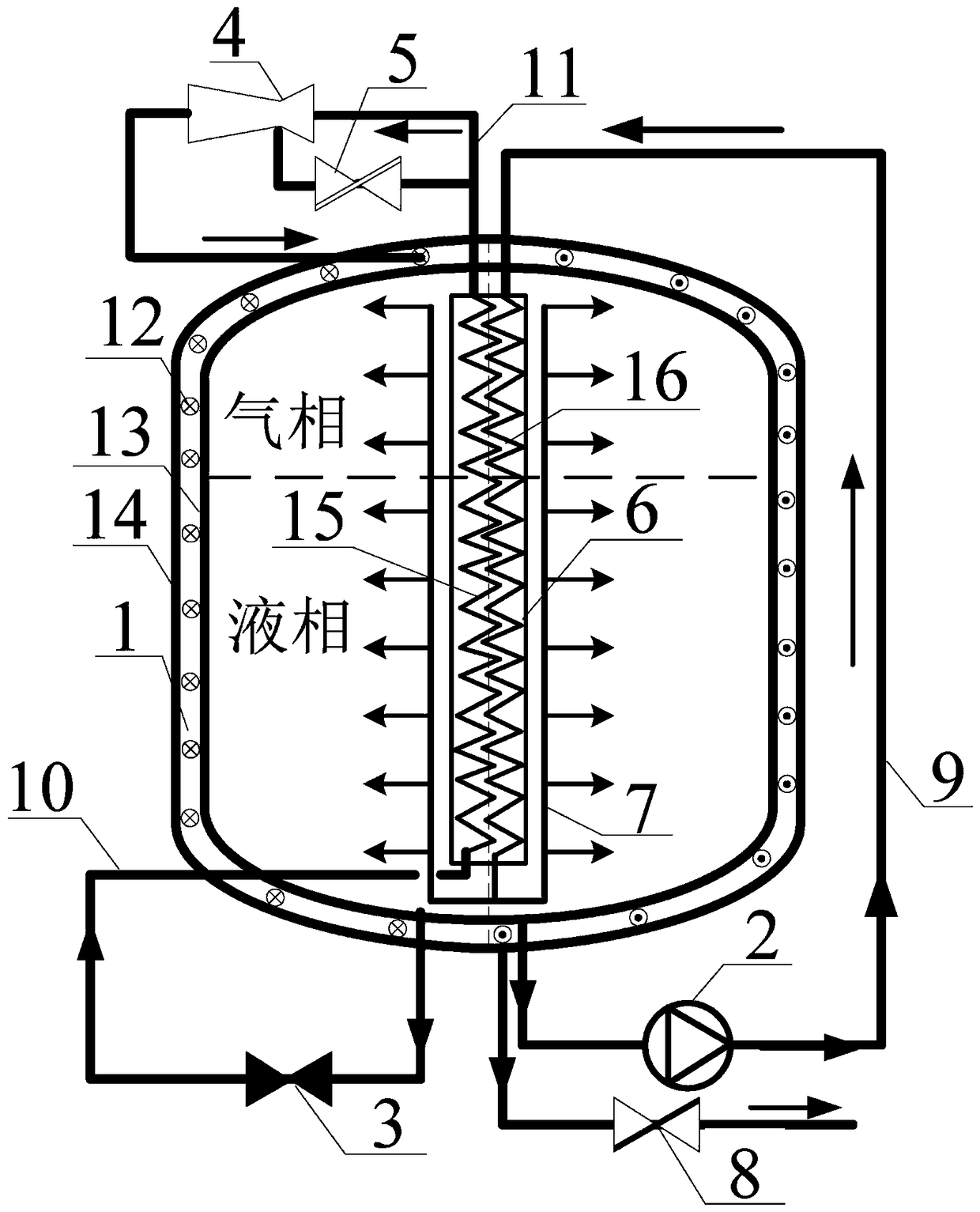

[0040] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0041] refer to figure 1 , a high-efficiency pressure-controlled low-temperature propellant storage tank with an injection device, including a storage tank body 1, a low-temperature circulation pump 2, a liquid throttle valve 3, an ejector 4, a gas throttle valve 5, and a counterflow casing Heat exchanger 6, exhaust cooling coil 12, fluid injection bar 7, exhaust valve 8, pipeline 9, pipeline 10, pipeline 11.

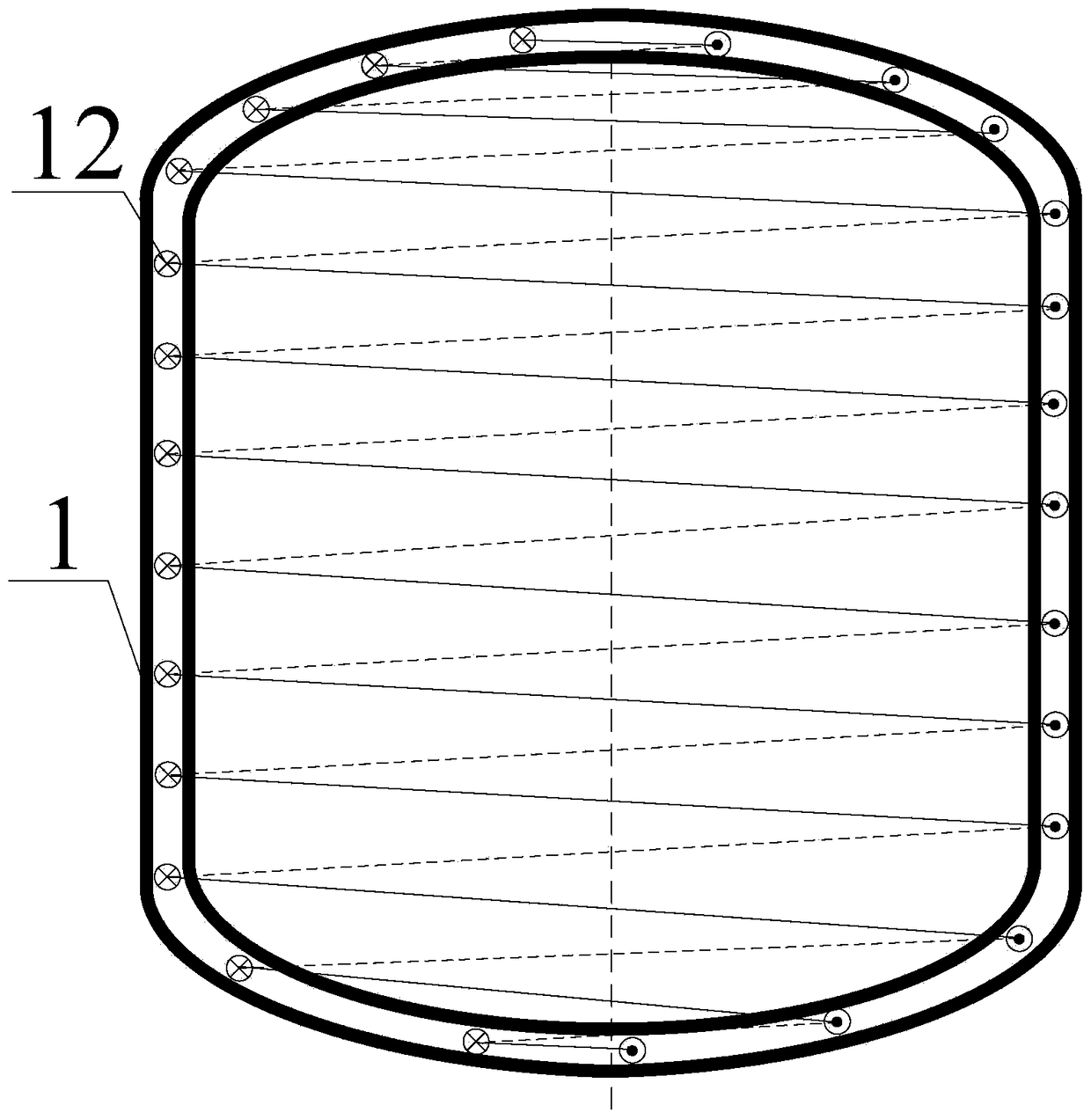

[0042] The storage tank body 1 includes an inner tank 13 and an outer tank 14, and the fluid in the tank is a low-temperature propellant, which is composed of a gas phase and a liquid phase respectively. Heat insulation material is filled between the inner and outer tank bodies, and the exhaust cooling coil 12 is located in the middle of the heat insulation material. The counterflow casing heat exchanger 6 is placed vertically inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com