Preparation method of metal mercury adsorbent, adsorbent and regeneration method

An adsorbent and metal mercury technology, which is applied in the field of preparation of metal mercury adsorbents, can solve the problems of difficulty in removing elemental mercury, difficult to regenerate, large consumption of adsorbents and the like, and achieves the effect suitable for industrial application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

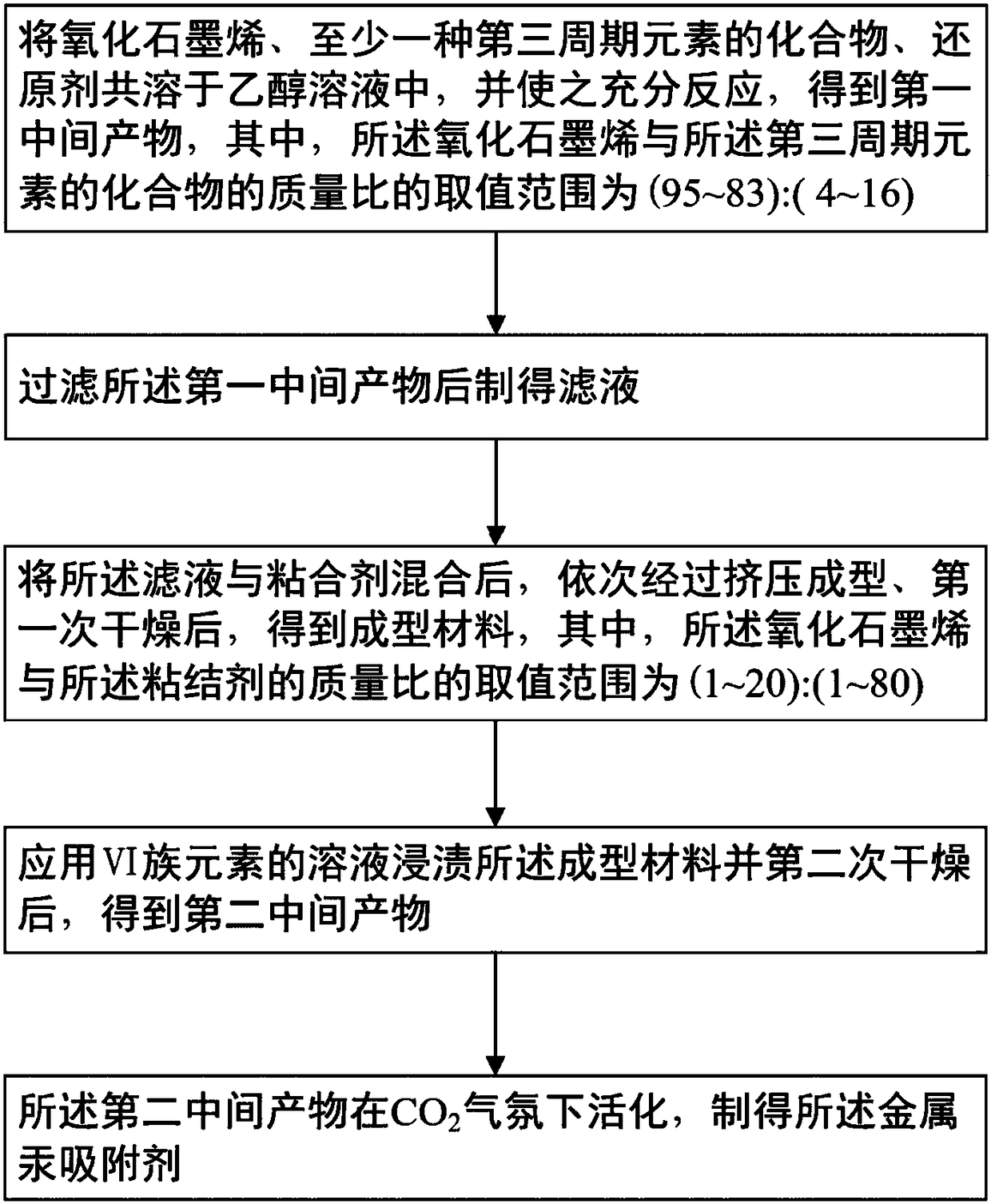

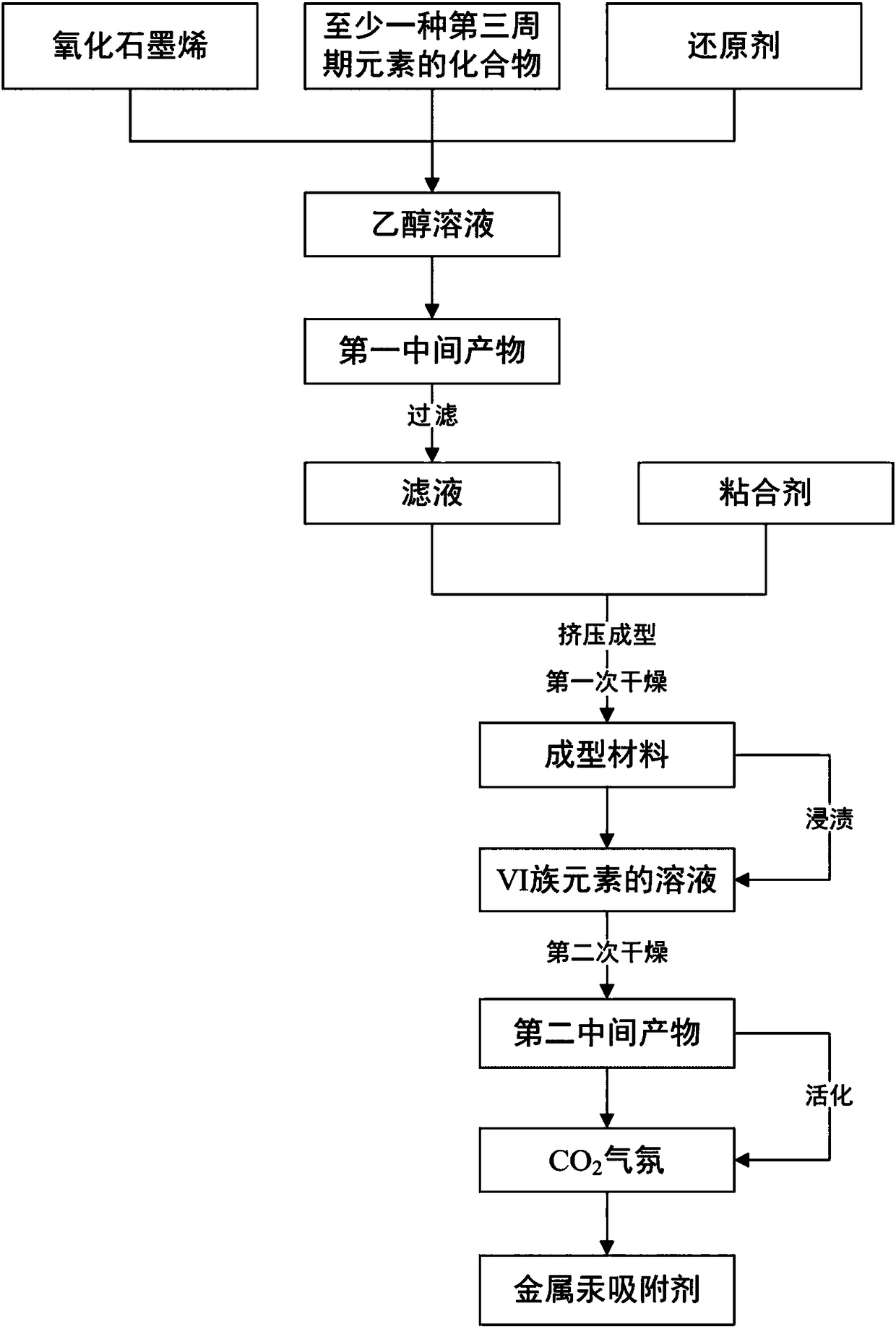

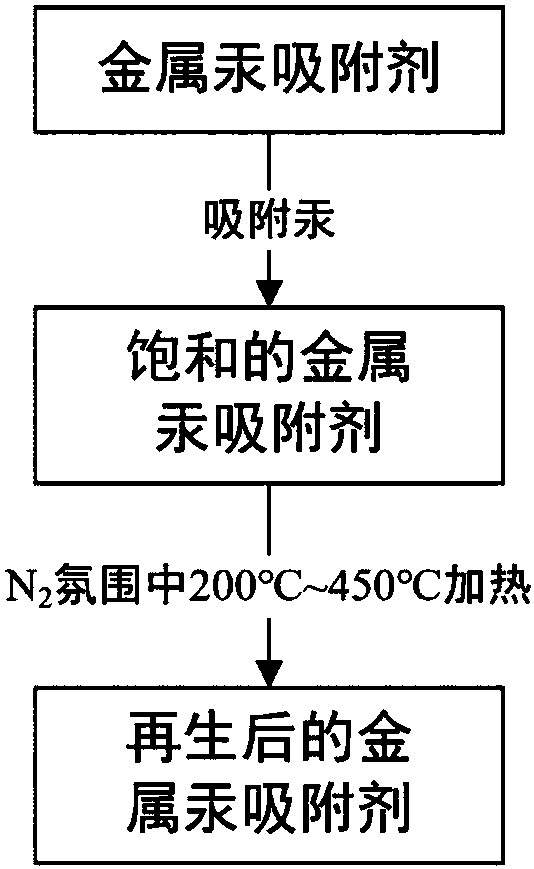

[0036] In order to solve the problems existing in the prior art, the present invention provides a method for preparing a metallic mercury adsorbent, the adsorbent and a regeneration method. The metallic mercury adsorbent prepared by using the preparation method has high mercury removal efficiency, and the metallic mercury After the adsorbent is regenerated by the regeneration method, it can still maintain a high mercury removal efficiency, so it is more suitable for application.

[0037] For further elaborating the technical means and effects that the present invention takes to reach the intended invention purpose, below in conjunction with accompanying drawing and preferred embodiment, to the preparation method of metal mercury adsorbent proposed according to the present invention, this adsorbent and this adsorbent The regeneration method after saturation, its specific implementation, structure, characteristics and efficacy are described in detail below. In the following desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com