Three-layer co-extruded composite film specially used for invisible correction and preparation method of composite film

A technology of three-layer co-extrusion and composite membrane, which is applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of poor material elasticity, low tear strength, low tensile strength, etc. Achieve the effect of improving elasticity and tear resistance, improving elasticity and tearing performance, and high biological safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

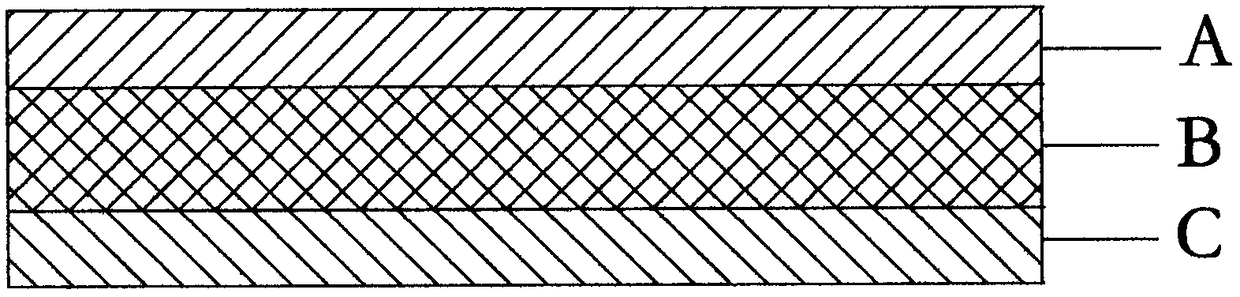

[0016] This embodiment provides a special three-layer co-extruded composite diaphragm for invisible correction, which has a three-layer structure, the surface layer A is DP9873D TPU of German Covestro (Bayer) company with a thickness of 0.25 mm and a hardness of 73D, and the middle layer is 0.3 mm thick. German Covestro (Bayer) company Makrolon 3108PC, the inner layer C is Elastollan 1195A TPU of German BASF company (BASF) with a thickness of 0.2 mm and a hardness of 95A.

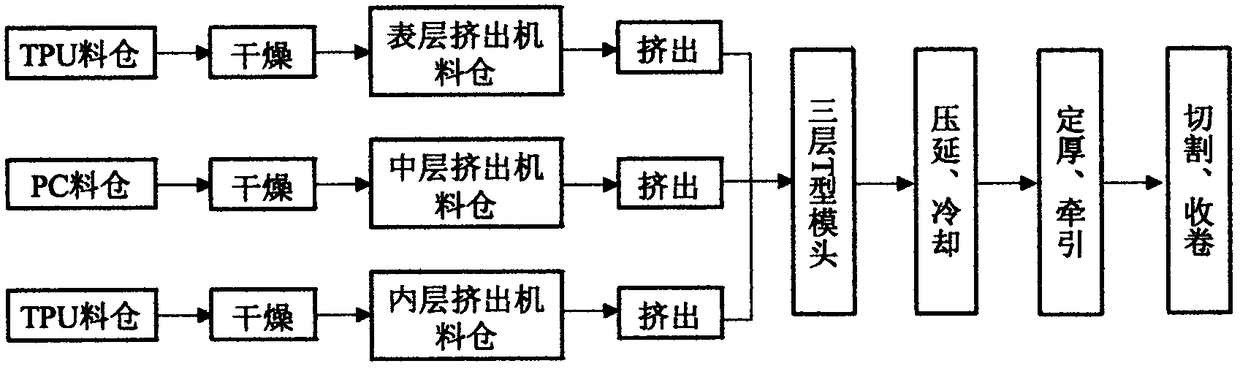

[0017] The preparation process of the three-layer co-extruded composite membrane for invisible correction is as follows: figure 2 As shown, the details are as follows:

[0018] (a) Drying: Dry Elastollan 1195A TPU at 110°C for 3 hours, dry Makrolon 3108PC at 130°C for 4 hours, and dry DP9873D TPU at 120°C for 3 hours;

[0019] (b) Extrusion: Add the dried Elastollan 1195A TPU, Makrolon 3108PC, and DP9873D TPU to three twin-screw extruders and extrude at the specified temperature. The processing temperatu...

Embodiment 2

[0025] This embodiment provides a special three-layer co-extruded composite diaphragm for invisible correction, which has a three-layer structure, the surface layer A is DP9873D TPU of German Covestro (Bayer) company with a thickness of 0.15 mm and a hardness of 73D, and the middle layer B is a thickness of 0.5 mm. The German Covestro (Bayer) company Makrolon 3108PC, the inner layer C is the Elastollan 1195A TPU of the German BASF company (BASF) with a thickness of 0.1mm and a hardness of 95A.

[0026] The preparation process of the three-layer co-extruded composite membrane for invisible correction is as follows: figure 2 As shown, the details are as follows:

[0027] (a) Dry Elastollan 1195A TPU at 110°C for 3 hours, dry Makrolon3108PC at 130°C for 4 hours, and dry DP9873D TPU at 120°C for 3 hours;

[0028] (b) Extrusion: Add the dried Elastollan 1195A TPU, Makrolon 3108PC, and DP9873D TPU to three twin-screw extruders and extrude at the specified temperature. The process...

Embodiment 3

[0034] This embodiment provides a special three-layer co-extruded composite membrane for invisible correction, which has a three-layer structure, the thickness of the surface layer A is DP9873D TPU of German Covestro (Bayer) company with a hardness of 73D, and the thickness of the middle layer B is 0.3mm. Makrolon 3108PC of Covestro (Bayer) Co., Ltd. of Germany, and the inner layer C is Elastollan 1195A TPU of BASF Co., Ltd. of Germany with a thickness of 0.3mm and a hardness of 95A.

[0035] The preparation process of the three-layer co-extruded composite membrane for invisible correction is as follows: figure 2 As shown, the details are as follows:

[0036] (a) Dry Elastollan 1195A TPU at 110°C for 3 hours, dry Makrolon 3108PC at 130°C for 4 hours, and dry DP9873D TPU at 120°C for 3 hours;

[0037] (b) Extrusion: Add the dried Elastollan 1195A TPU, Makrolon 3108PC, and DP9873D TPU to three twin-screw extruders and extrude at the specified temperature. The processing tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com