Recoverable side slope temporary protection structure and construction method thereof

A technology for temporary protection and slope, applied in infrastructure engineering, excavation, construction, etc., can solve the problems that concrete materials cannot be recycled and reused, cannot meet the construction progress, and a large amount of construction waste, etc., so that the construction quality is easy to guarantee and can be turned over Strong, environmentally friendly assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

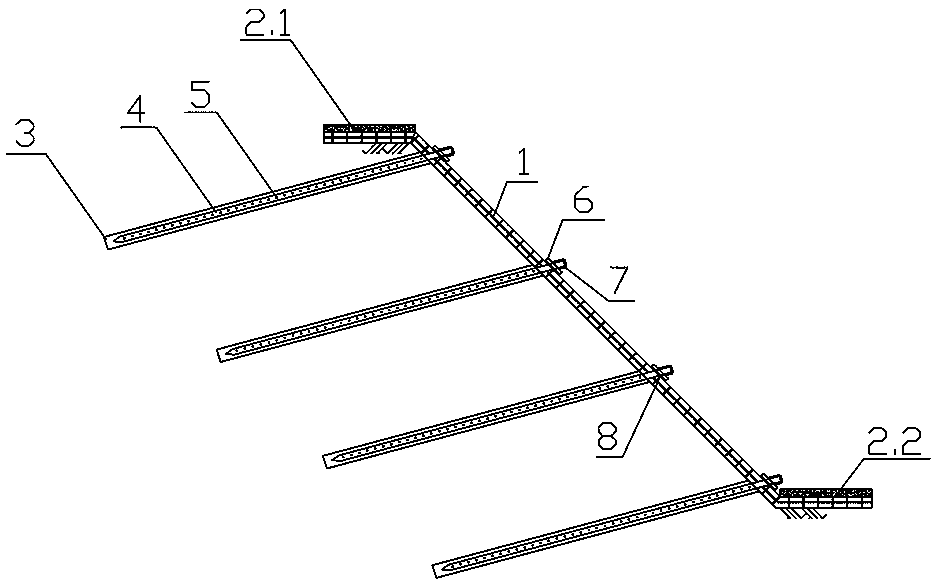

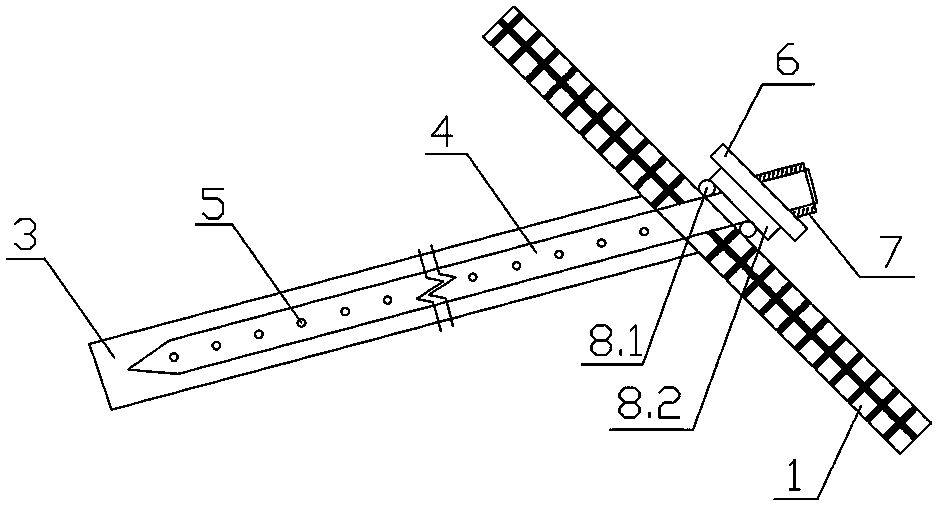

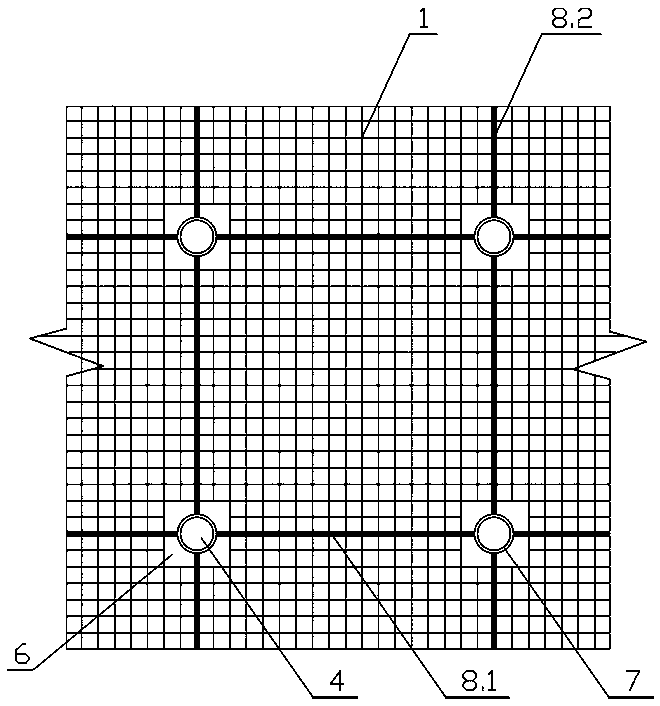

[0018] Such as Figure 1-4 As shown, the recyclable slope temporary protection structure described in the present invention includes a zigzag-like dense-hole FRP grating panel 1 laid along the slope surface, which includes successively connected upper horizontal sections, inclined sections and lower horizontal sections, Concrete topping 2.1 and 2.2 are respectively poured in the upper horizontal section and the lower horizontal section to firmly fix the grid panel 1 on the slope soil; secondly, evenly distributed reserved holes are opened on the slope soil 3. Each reserved hole 3 is built with a hollow steel pipe 4 whose head is pointed and anchored. The inner cavity of the hollow steel pipe 4 is filled with cement slurry under medium pressure. The through hole 5 of the through hole 5 fills the gap of the reserved hole 3; the tail of the hollow steel pipe 4 extends through the steel pipe piercing hole provided on the grid panel 1, and then a crimping steel plate 6 is sleeved, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com