Valveless electromagnetic micro pump and manufacturing method thereof

An electromagnetic and micro-pump technology, applied in biochemical equipment and methods, pumps, pump components, etc., can solve the problem that micro-pump technology is difficult to achieve portability, and achieve the effect of miniaturized packaging, small size, and enhanced portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

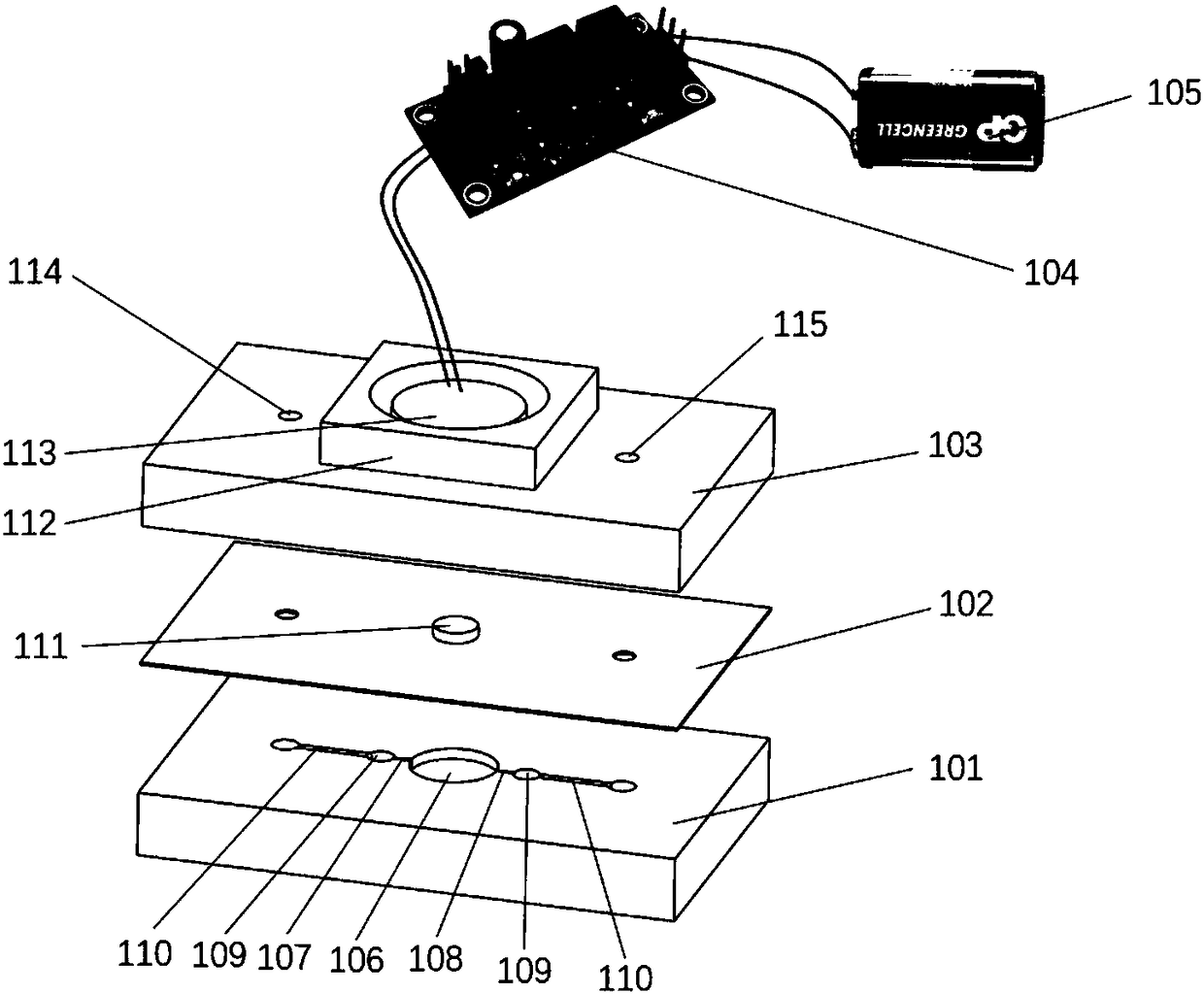

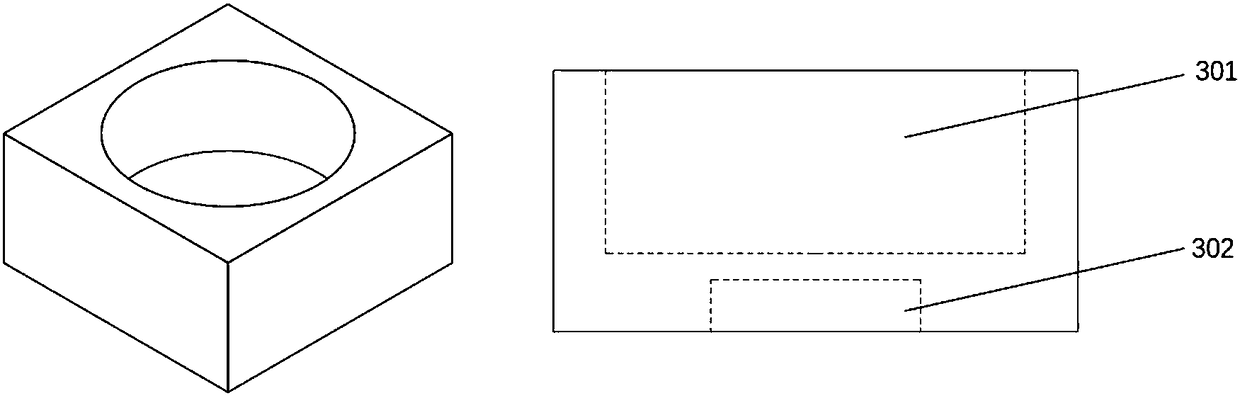

[0059] refer to Figure 1 to Figure 6 , a valveless electromagnetic micropump for two-organ co-culture chip, which consists of a pump body and a power supply system. The power system includes a signal generating module 104 and a battery 105 . The pump body is composed of a pump chamber layer 101 , a film layer 102 and a coil layer 103 in a three-layer structure from bottom to top.

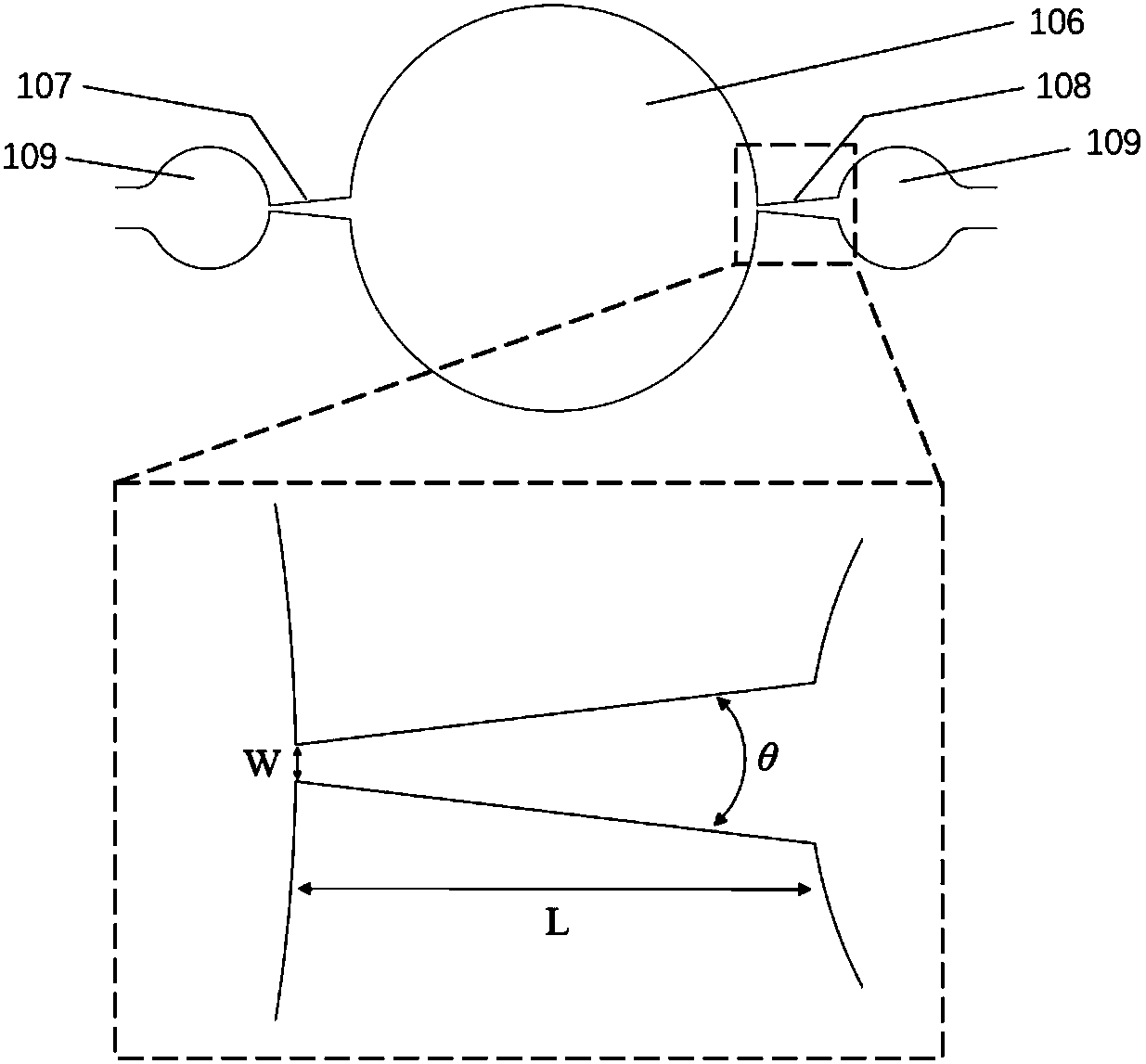

[0060] The structure of the pump cavity layer 101 includes a pump cavity 106 , a first expansion and contraction tube 107 , a second expansion and contraction tube 108 , a buffer cavity 109 , a microchannel 110 and an organ model cavity 601 . The pump chamber 106 is connected to the buffer chambers 109 on both sides through the first expansion and contraction tube 107 and the second expansion and contraction tube 108. The buffer chambers 109 on both sides are respectively connected to the micro-channels 110 on both sides. An organ model cavity 601 forms a loop.

[0061] The first expansion and c...

Embodiment 2

[0075] refer to Figure 1 to Figure 4 , Figure 7 to Figure 8 , a series-parallel model of a valveless electromagnetic micropump consisting of a pump body and a power system. The power system includes a signal generating module 104 and a battery 105 . The pump body is composed of a pump chamber layer 101 , a film layer 102 and a coil layer 103 in a three-layer structure from bottom to top.

[0076] The pump chamber layer 101 structure includes micropump A801, micropump B802, micropump C803, main channel 806, branch channel A804 and branch channel 805. Each micropump includes a pump cavity 106 , a first expansion-contraction tube 107 , a second expansion-contraction tube 108 and a buffer cavity 109 . The pump chamber 106 is connected to the buffer chambers 109 on both sides through the first expansion and contraction tube 107 and the second expansion and contraction tube 108. The buffer chambers 109 on both sides of the micropump A801 are connected to the branch channel A8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com