SMC integrated photovoltaic module, manufacturing method and application

A photovoltaic module and integrated technology, applied in the field of solar cells, can solve the problems of backplane damage, shortened component life, battery board circuit corrosion, etc., and achieve the effects of stable bonding and sealing structure, excellent mechanical properties, and excellent waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

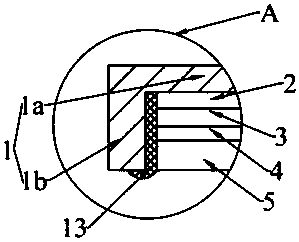

[0064] like Figure 1-4 As shown, Example 1 SMC monolithic photovoltaic module includes an open groove 1 made of SMC material, and the bottom plate 1a of the open groove 1 is sequentially vacuum laminated and bonded to be provided with a first sealing adhesive layer 2, a battery sheet 3, a second Two sealing adhesive layers 4, light-transmitting panels 5; the bottom plate of the open slot 1 is provided with a through hole 7 through which the bus bar lead-out line 6 of the battery sheet 3 passes, and the open slot 1 is provided with a bus bar lead-out line 6 connected to the junction box 8, the first sealing adhesive layer 2, the battery sheet 3, the second sealing adhesive layer 4, the outer edge of the light-transmitting panel 5 and the side wall 1b of the open groove 1, and the bus bar lead-out wire 6 A filling glue 13 is sealed between the through hole 7 and the through hole 7 .

[0065] The open slot in embodiment 1 is composed of a base plate and a frame-shaped side wall...

Embodiment 2

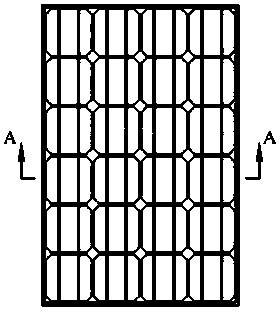

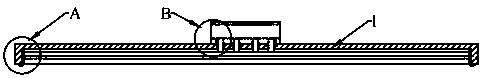

[0073] like Figure 2-8 As shown, the difference between embodiment 2 and embodiment 1 is that the outer surface of the bottom plate of the open groove 1 is provided with reinforcing ribs 9 ; the outer surface of the bottom plate of the open groove is also provided with frame-shaped protrusions 10 . The ribs 9 are grid-shaped.

[0074] The frame-shaped protrusion 10 is opposite to the side wall of the open groove 1 on the surface of the bottom plate 1a, that is, the frame-shaped protrusion 10 extends from the side wall 1b of the open groove to the back of the bottom plate.

[0075] The reinforcing rib 9 and the frame-shaped protrusion 10 can be separately arranged on the open groove 1 .

[0076] In Embodiment 2, the cross section of the side wall 1b of the open groove is in the shape of a right-angled trapezoid, and the inclined side of the side wall 1b is located at the inner edge of the frame-shaped side wall.

[0077] The junction box is arranged on the outer surface of t...

Embodiment 3

[0079] like Figure 9 As shown, Embodiment 3 is based on Embodiment 2. The surface of the component is embedded with a connector 11, which is used to connect the SMC integral photovoltaic module to the base surface, and the connector 11 is embedded in the open groove. on the side wall. Specifically, the pre-embedded connectors are nuts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com