Rotor position detection method of vehicle permanent magnet synchronous motor

A permanent magnet synchronous motor, rotor position detection technology, applied in the estimation/correction of motor parameters, motor control, electronic commutator and other directions, can solve the problems of complex control algorithm, high cost and high parameter requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawings and examples.

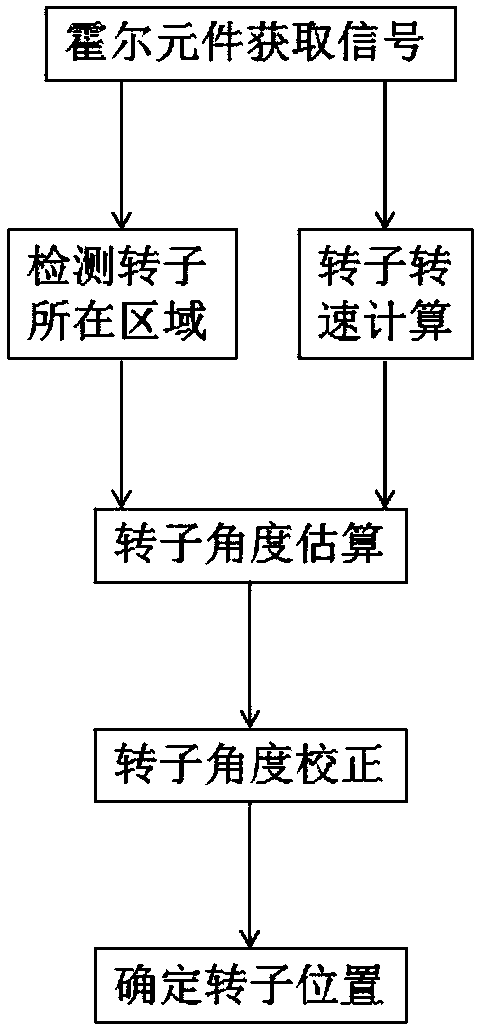

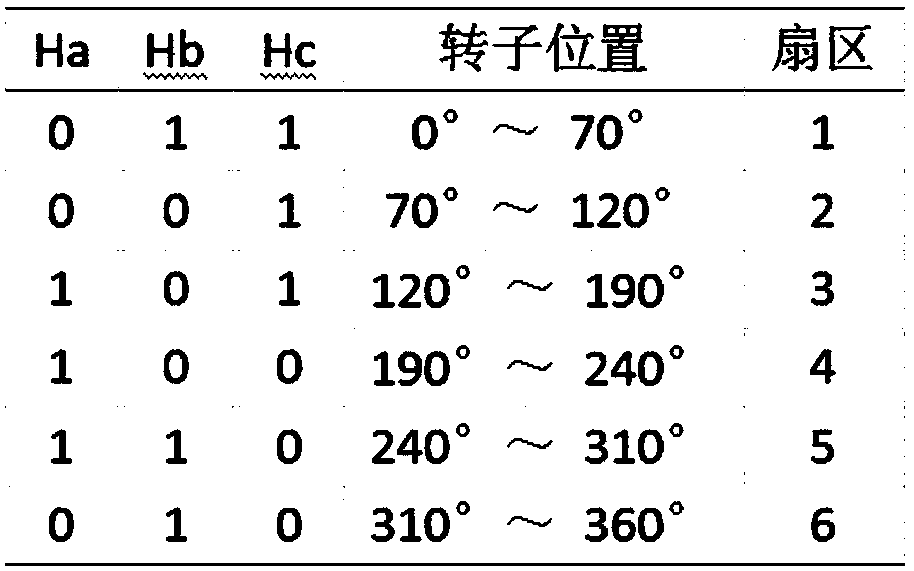

[0020] figure 1 It is a process flowchart of a method for detecting the rotor position of a permanent magnet synchronous motor for vehicles. After the Hall element obtains the signal, on the one hand, the corresponding relationship between the Hall signal and the rotor angle is used to determine which area the rotor is located in, and on the other hand, the rotor speed is calculated by the T method; it can be estimated according to the obtained rotor area and rotor speed Rotor angle; then correct the rotor angle by using the slow angle correction method, so that the position of the rotor can be determined.

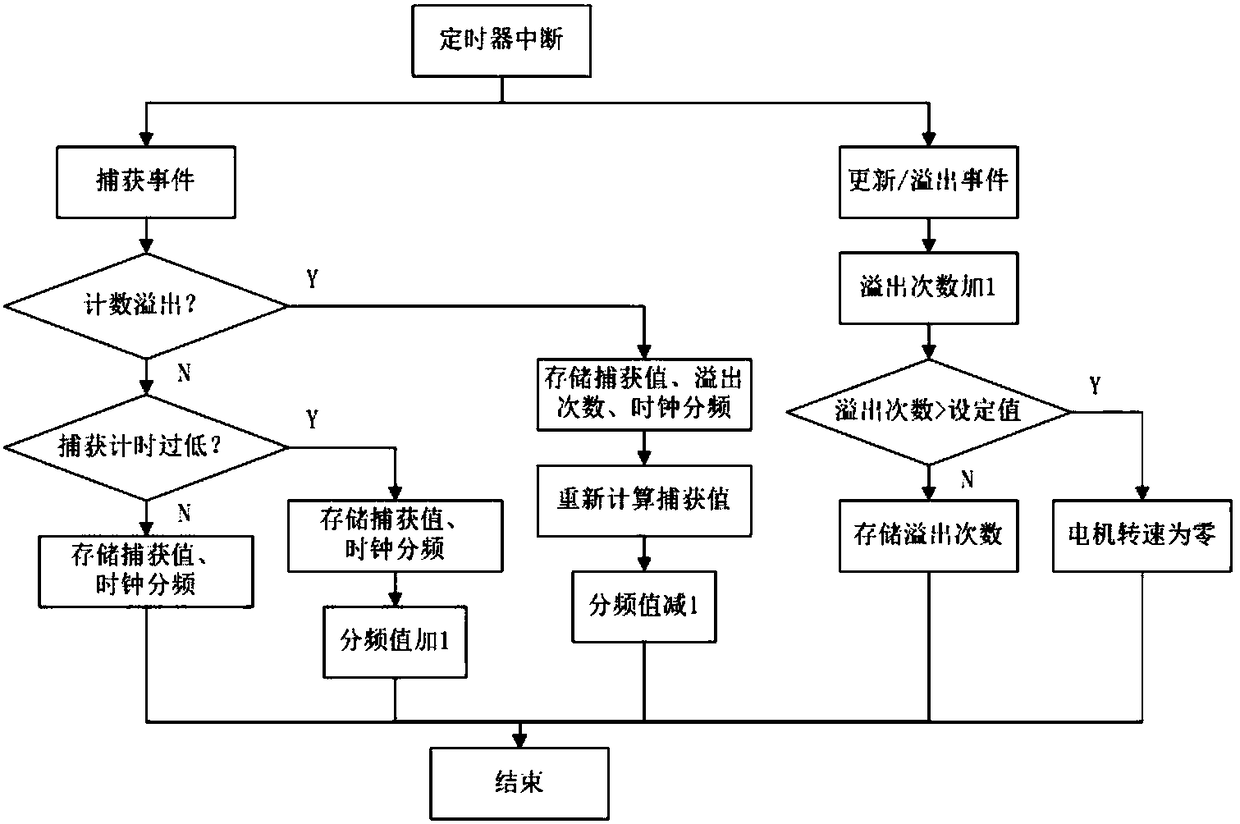

[0021] image 3 It is a flow chart of the process of setting the frequency division value of the input capture timer when calculating the rotational speed of a rotor position detection method of a permanent magnet synchronous motor for vehicles. Configu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com