Method and device for preventing scaling and blocking of garbage landfill site by utilizing slag and landfill gas

A landfill and landfill gas technology, applied in landfill technology, solid waste removal, waste fuel, etc., can solve the problem of low processing efficiency, high processing cost, and long processing time (it takes several weeks) To achieve the effect of reducing energy consumption, maintaining normal operation, and reducing the risk of fouling and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

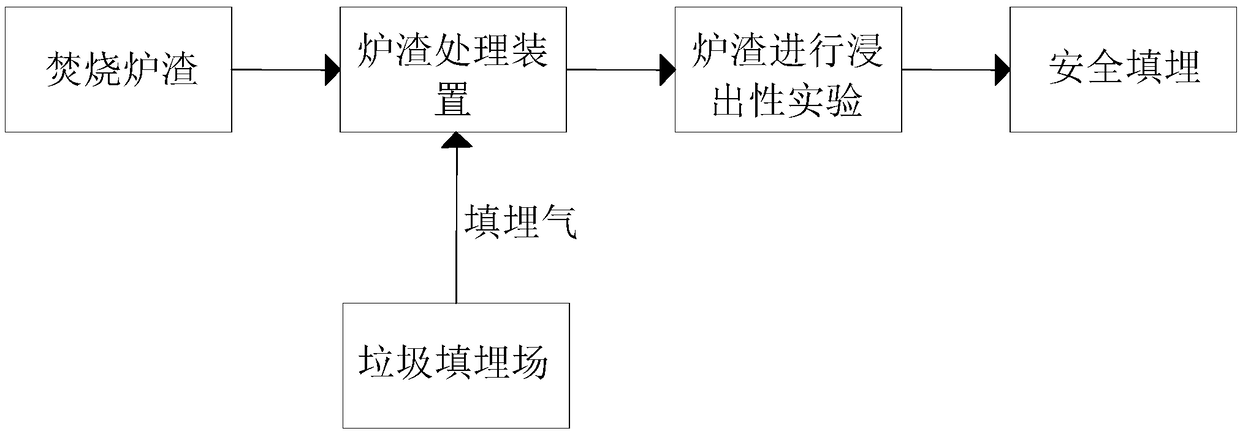

[0049] A method for preventing scaling and clogging of landfills by using the above-mentioned device, such as figure 1 shown, including the following steps:

[0050] 1) The slag in the grate opening of the waste incinerator (see XRD for the slag before the reaction) Figure 4 ) is collected, and 50g of slag is taken to the treatment room, and the airtight treatment room is closed;

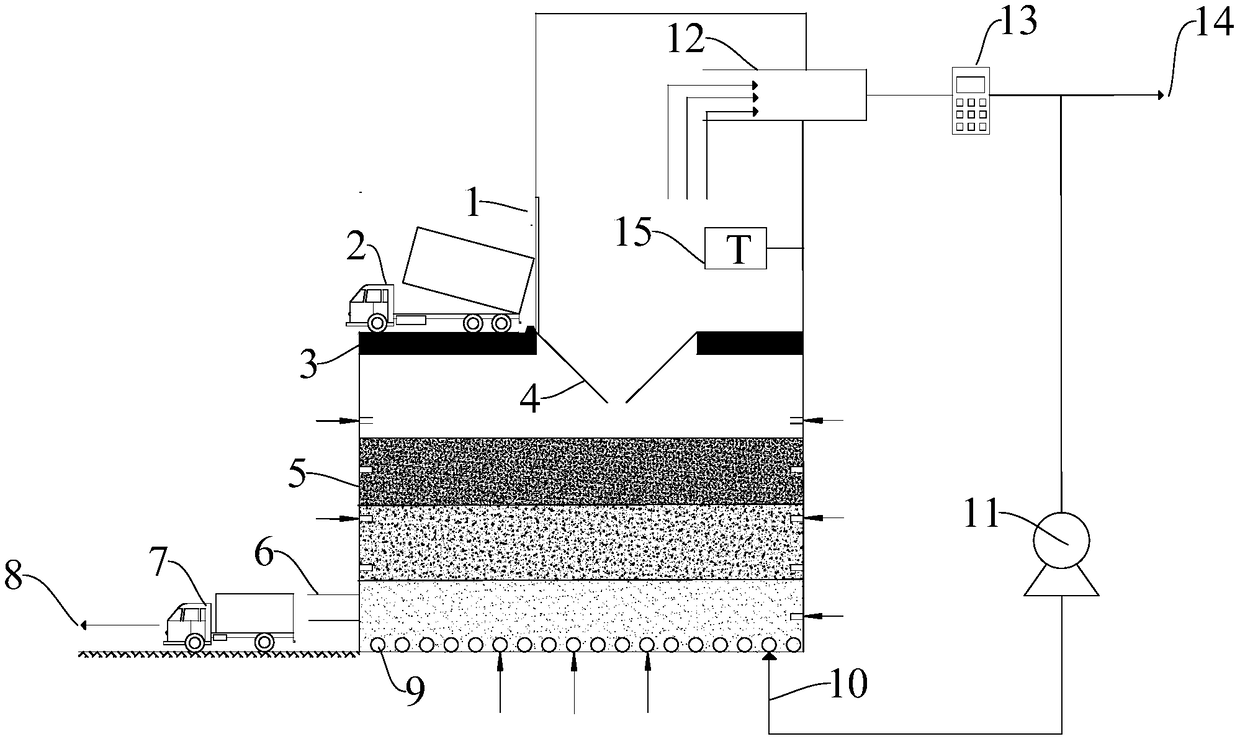

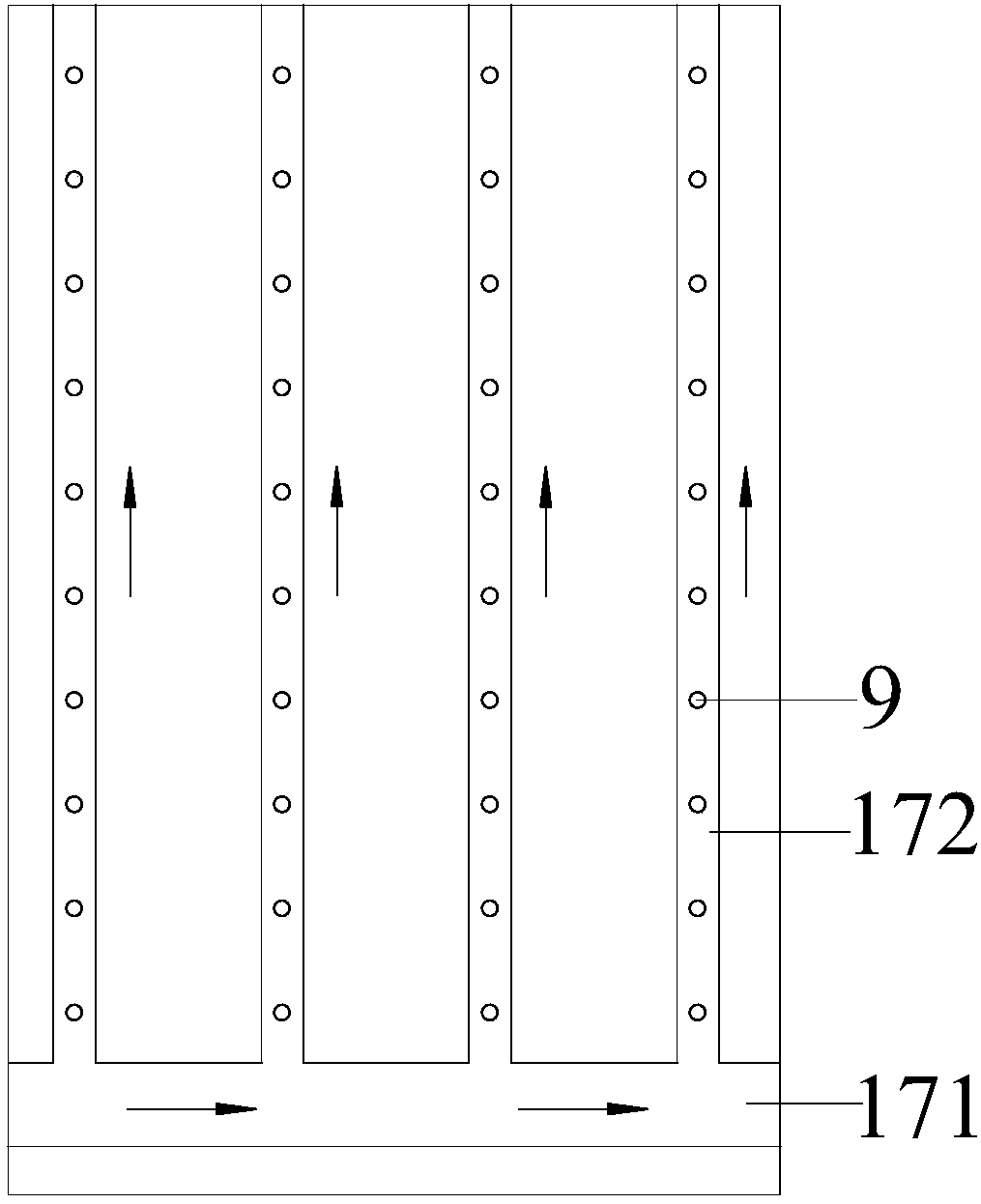

[0051] 2) The landfill gas composed of 60% methane and 40% carbon dioxide is transported to the treatment room through the intake pipeline, and the air guide pipes are evenly arranged on the bottom and both sides of the treatment room, and the intake flow rate is 50mL / min to ensure that the slag and landfill gas Fully contact for reaction, the reaction temperature is 35°C;

[0052] 3) Install a gas monitor at the exhaust port to monitor CO at any time 2 The CO concentration in the landfill gas enters the processing room through the circulation pump to continue processing. After 8 hours of reacti...

Embodiment 2

[0060] A method for preventing scaling and clogging of landfills by using the above-mentioned device, comprising the following steps:

[0061] 1) Collect the slag in the grate opening of the garbage incinerator, take 50g and fill it into the treatment room, and seal the treatment room;

[0062] 2) The landfill gas composed of 60% methane and 40% carbon dioxide is transported to the treatment room through the intake pipeline, and the air guide pipes are evenly arranged on the bottom and both sides of the treatment room, with a flow rate of 31.32mL / min to ensure sufficient slag and landfill gas Contact for reaction, the reaction temperature is 20°C;

[0063] 3) Install a gas monitor at the exhaust port to monitor CO at any time 2 Concentration, enter the treatment room through the circulation pump to continue processing, after 7 hours of reaction, the CO in the landfill gas 2 The concentration is 19.14% (lower than 20%), and the collected and reacted landfill gas is directly t...

Embodiment 3

[0070] A method for preventing scaling and clogging of landfills by using the above-mentioned device, comprising the following steps:

[0071] 1) Collect the slag in the grate opening of the garbage incinerator, take 50g of the slag to the treatment room, and seal the treatment room;

[0072] 2) The landfill gas composed of 60% methane and 40% carbon dioxide is transported to the treatment room through the intake pipeline, and the air guide pipes are evenly arranged on the bottom and both sides of the treatment room, and the intake flow rate is 50mL / min to ensure that the slag and landfill gas Fully contact for reaction, the reaction temperature is 30°C;

[0073] 3) Install a gas monitor at the exhaust port to monitor the CO2 concentration at any time, and enter the treatment room through the circulation pump to continue processing. After a reaction time of 8 hours, the CO2 concentration in the landfill gas is 19.2% (less than 20%). The landfill gas is directly transported to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com