A weaving method for cooling tower bamboo lattice filling

A cooling tower and water spraying technology, which is applied in the direction of sugarcane machining, mechanical equipment, etc., can solve the unpredictability of the service life of bamboo grid water spraying filler, can not effectively solve the problem of connecting bamboo slices and bamboo slices, and can not be continuous Mechanized production and other issues, to achieve the effect of simple and fast paving method, improve anti-corrosion and anti-mildew characteristics, and reduce on-site paving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

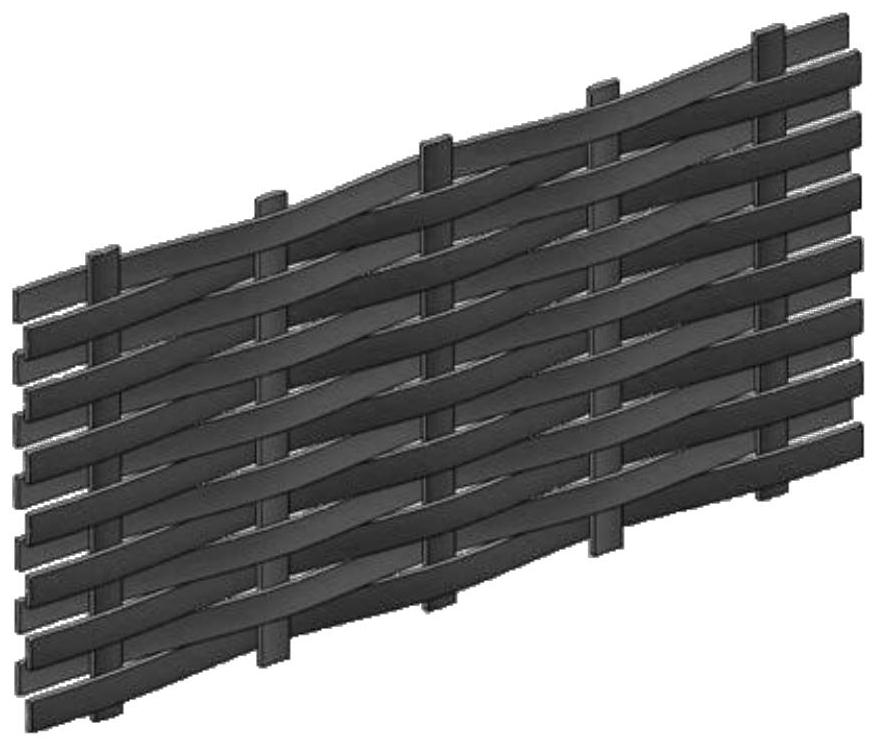

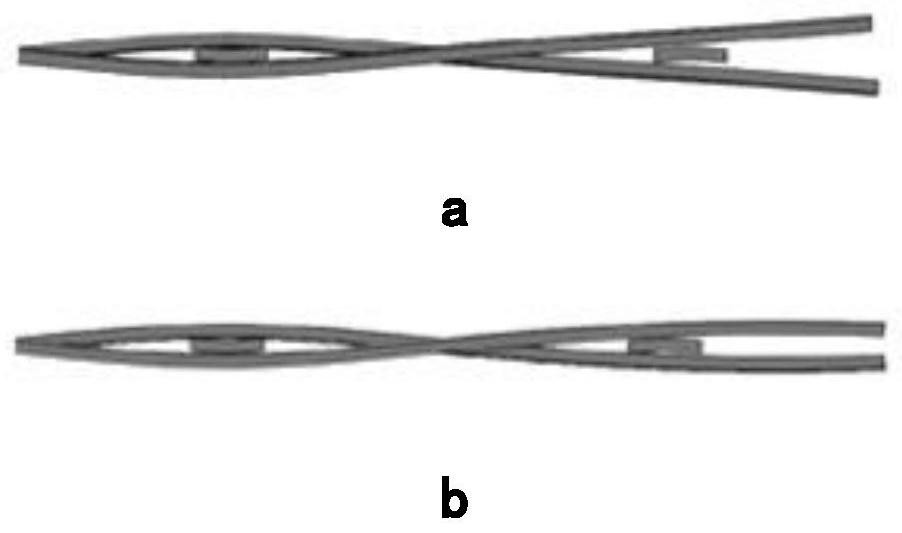

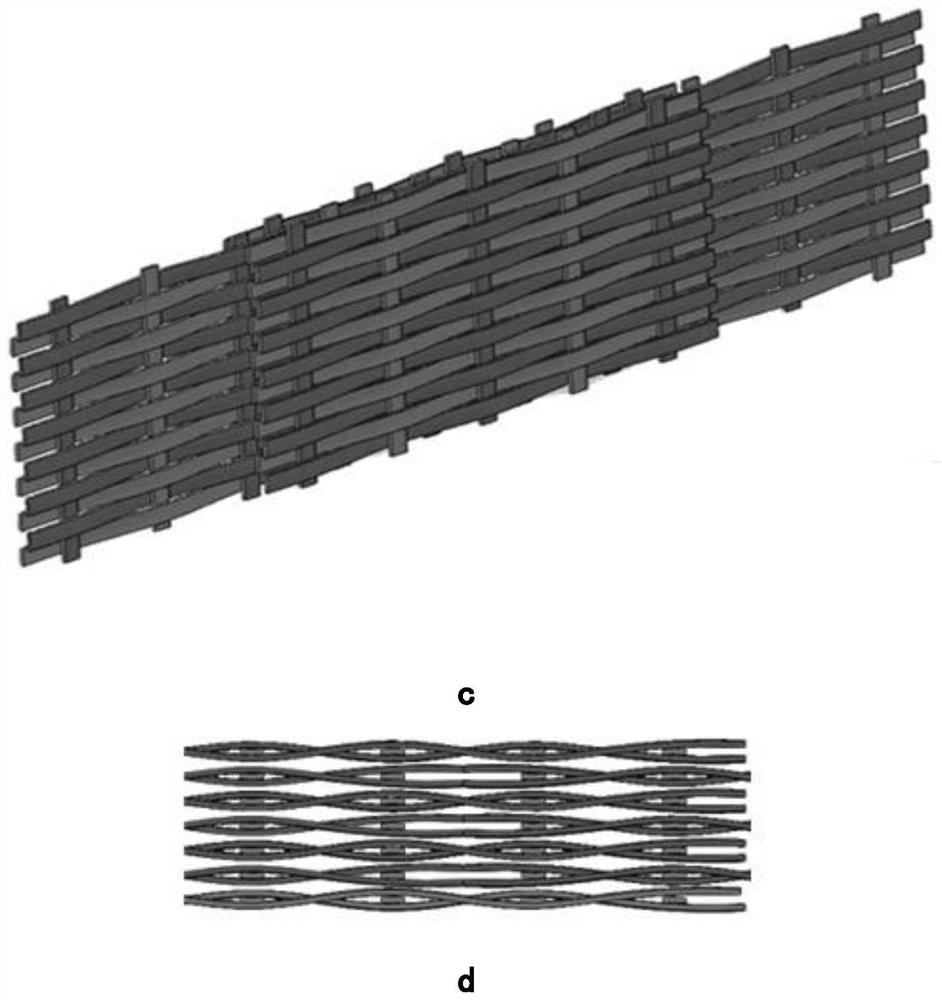

[0028] A method for weaving cooling tower bamboo grid water-sprinkling fillers, comprising the following steps:

[0029] S1. Select the 4-5 year old moso bamboo or other bamboo species that grow well, sort according to the diameter of the round bamboo, preferably the excellent bamboo with a diameter of about 12cm-15cm and a bamboo wall thickness of 1cm, and cut upwards from the height of about 150cm from the ground 300cm to 900cm long bamboo tube, this length can be adjusted according to the different growth conditions of bamboo species;

[0030] S2. Saw the above-mentioned bamboo tube into bamboo sections with a length of 300cm and 150cm, and then use a bamboo splitter to divide the bamboo section into 3-4 equal bamboo slices along the growth direction. The final specifications of the bamboo slices are: horizontal weaving Bamboo slices are 300cm long * 4cm wide * 1cm thick; radially woven bamboo slices are 150cm long * 4cm wide * 1cm thick; in actual production, the length ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com