Production method of high concentration ozone water

A production method and ozone water technology, applied in chemical instruments and methods, water/sewage treatment, water/sewage treatment equipment, etc., can solve the problems of low ozone amount, inability to reach the market, and inability to expand the production and sales of ozone water. , to achieve high ozone concentration, improve ozone yield, and achieve significant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

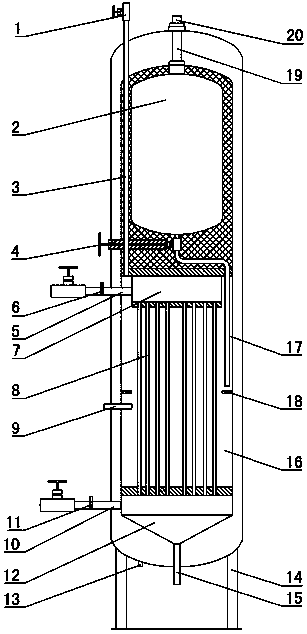

[0033] A method for producing high-concentration ozone water, comprising the steps of:

[0034] Step 1), performing corona discharge on oxygen to form a mixed gas of oxygen and ozone;

[0035] The liquid oxygen is stored in the liquid oxygen tank, and the liquid oxygen in the liquid oxygen tank passes through the vaporizer to form oxygen, and then removes impurities from the oxygen. The impurity removal of oxygen is carried out by heating oxygen to remove oily carbon monoxide, methane, acetylene and other flammable gas impurities in the ozone produced by industrial oxygen, so as to avoid affecting the production of ozone. The oxygen is removed by heating, and the heated oxygen exchanges heat with the oxygen before heating, so as to avoid energy waste.

[0036] The decontaminated oxygen enters the ozone generating device, and corona discharge is carried out in the ozone generating device to form a mixed gas of ozone and oxygen.

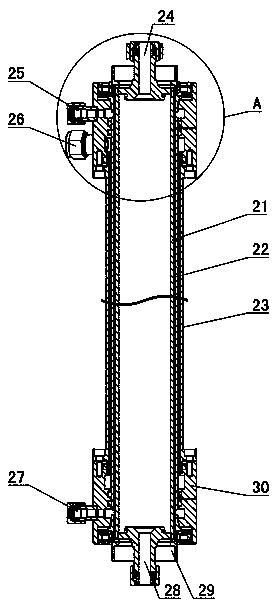

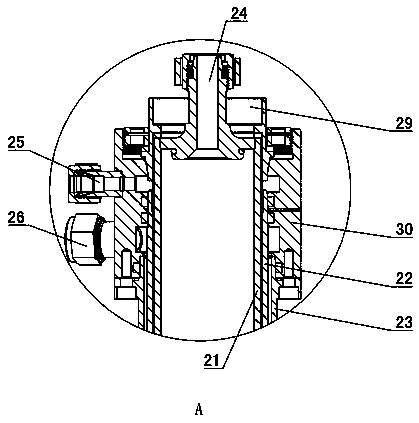

[0037] Such as Figure 1~2 Shown: The ozone g...

Embodiment 2

[0062] A method for producing high-concentration ozone water, comprising the steps of:

[0063] Step 1), performing corona discharge on oxygen to form a mixed gas of oxygen and ozone;

[0064] The liquid oxygen is stored in the liquid oxygen tank, and the liquid oxygen in the liquid oxygen tank passes through the vaporizer to form oxygen, and then removes impurities from the oxygen. The impurity removal of oxygen is carried out by heating oxygen to remove oily carbon monoxide, methane, acetylene and other flammable gas impurities in the ozone produced by industrial oxygen, so as to avoid affecting the production of ozone. The oxygen is removed by heating, and the heated oxygen exchanges heat with the oxygen before heating, so as to avoid energy waste.

[0065] The decontaminated oxygen enters the ozone generating device, and corona discharge is carried out in the ozone generating device to form a mixed gas of ozone and oxygen.

[0066] Step 2), under the pressure condition o...

Embodiment 3

[0072] A method for producing high-concentration ozone water, comprising the steps of:

[0073] Step 1), performing corona discharge on oxygen to form a mixed gas of oxygen and ozone;

[0074] The liquid oxygen is stored in the liquid oxygen tank, and the liquid oxygen in the liquid oxygen tank passes through the vaporizer to form oxygen, and then removes impurities from the oxygen. The impurity removal of oxygen is carried out by heating oxygen to remove oily carbon monoxide, methane, acetylene and other flammable gas impurities in the ozone produced by industrial oxygen, so as to avoid affecting the production of ozone. The oxygen is removed by heating, and the heated oxygen exchanges heat with the oxygen before heating, so as to avoid energy waste.

[0075] The decontaminated oxygen enters the ozone generating device, and corona discharge is carried out in the ozone generating device to form a mixed gas of ozone and oxygen.

[0076] Step 2), under the pressure of 0.2Mpa, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com